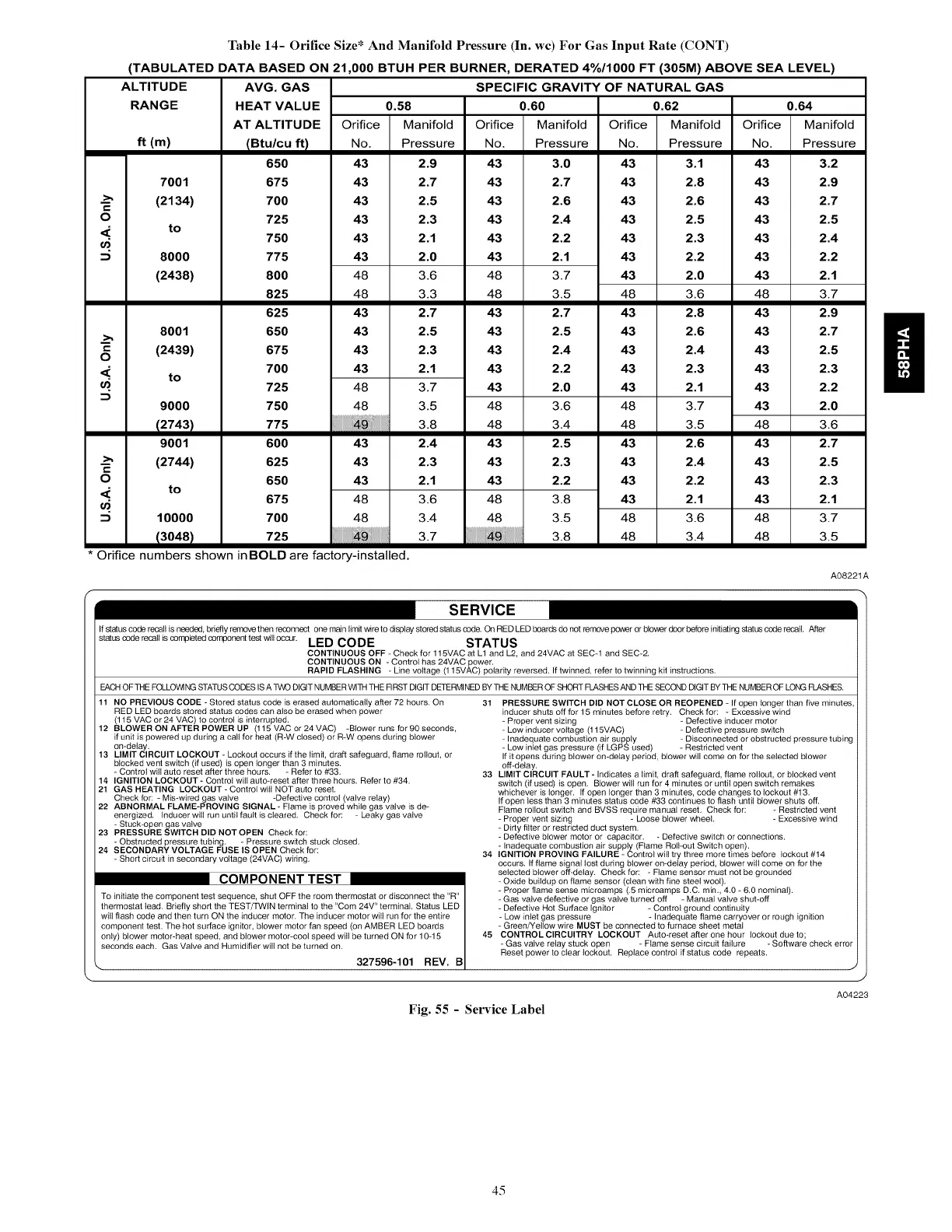

Table 14- Orifice Size* And Manifold Pressure (In. wc) For Gas Input Rate (CONT)

(TABULATED DATA BASED ON 21,000 BTUH PER BURNER, DERATED 4%/1000 FT (305M) ABOVE SEA LEVEL)

ALTITUDE AVG. GAS SPECIFIC GRAVITY OF NATURAL GAS

RANGE HEAT VALUE 0.58 0.60 0.62 0.64

ft (m)

AT ALTITUDE Orifice Manifold Orifice Manifold Orifice Manifold Orifice Manifold

/Btu/cu ft I No. Pressure No. Pressure No. Pressure No. Pressure

/

650 43 2.9 43 3.0 43 3.1 43 3.2

7001 675 43 2.7 43 2.7 43 2.8 43 2.9

--_ (2134) 700 43 2.5 43 2.6 43 2.6 43 2.7

C

O 725 43 2.3 43 2.4 43 2.5 43 2.5

to

750 43 2.1 43 2.2 43 2.3 43 2.4

8000 775 43 2.0 43 2.1 43 2.2 43 2.2

(2438)

800 48 3.6 48 3.7 43 2.0 43 2.1

825 48 3.3 48 3.5 48 3.6 48 3.7

C

O

625 43 2.7 43 2.7 43 2.8 43 2.9

m

8001 650 43 2.5 43 2.5 43 2.6 43 2.7

U

(2439) 675 43 2.3 43 2.4 43 2.4 43 2.5

700 43 2.1 43 2.2 43 2.3 43 2.3

to

725 48 3.7 43 2.0 43 2.1 43 2.2

9000 750 48 3.5 48 3.6 48 3.7 43 2.0

C

o

(2743) 775 3.8 48 3.4 48 3.5 48 3.6

/ /

9001 600 43 2.4 43 2.5 43 2.6 43 2.7

(2744) 625 43 2.3 43 2.3 43 2.4 43 2.5

650 43 2.1 43 2.2 43 2.2 43 2.3

to

675 48 3.6 48 3.8 43 2.1 43 2.1

10000 700 48 3.4 48 3.5 48 3.6 48 3.7

t3048) 725 3.7

* Orifice numbers shown in BOLD are factory-installed.

3.8 48 3.4 48 3.5

A08221A

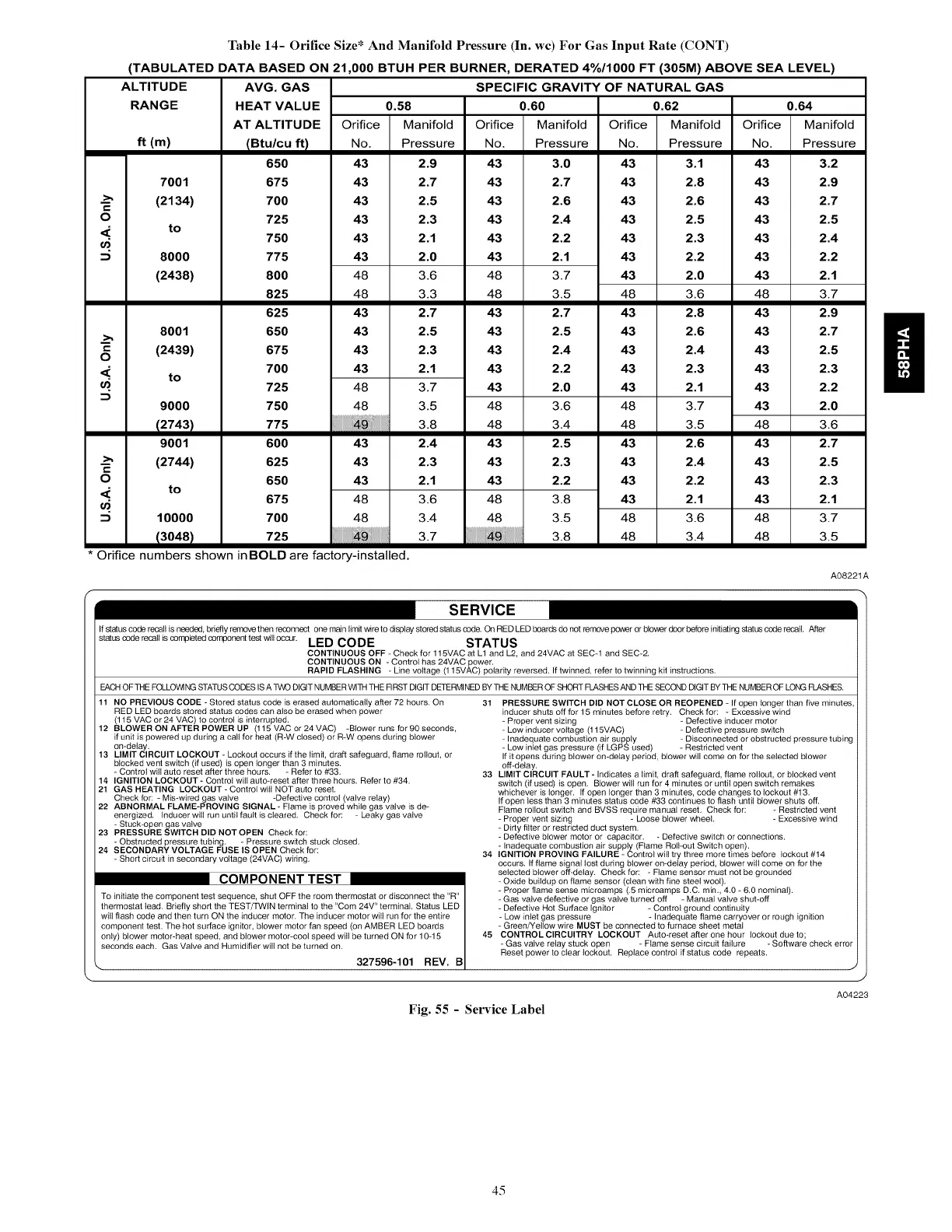

If status code recall is needed, briefly remove then recomect one main limit wire to display stored status code. On RED LED boards do not remove power or blower door before initiating statL_s cede recall After

staiL_S code recall is completed component test will occur. LED CODE STATUS

CONTINUOUS OFF - Check for 115VAC at L1 and L2, and 24VAC at SEC-1 and SEC-2,

CONTINUOUS ON - Control has 24VAC power,

RAPID FLASHING - Line voltage (115VAC) polarity reversed, If twinned, refer to twinning kit instructions,

EACH OF THE FOLLOW1NG STATUS CODES IS A ]WO DIGIT NUMBER Wl]]-I THE FI RST DIGIT DETERMI NED BY THE NUMBER OF SHORT FLASHES AND THE SECOND DIGIT BY THE NUMBER OF LONG FLASHES.

11 NO PREVIOUS CODE - Stored status code is erased automatically after 72 hours, On 31 PRESSURE SWITCH DID NOT CLOSE OR REOPENED - If open longer than five minutes

RED LED boards stored status codes can also be erased when power inducer shuts off for15 minutes before retry, Checkfor: -Excassivewied

(115 VAC or 24 VAC) to control is interrupted, - Proper vent sizing - Defective inducer motor

12 BLOWER ON AFTER POWER UP (115 VAC or 24 VAC) -Btower runs for 90 seconds, - Low inducer vottage (115VAC) - Defective pressure switch

if unit is powered Lip during a cali for heat (R-W closed) or R-W opens during biower - Inadequate combustion air suppiy - Disconnected or obstructed pressure tubinco

on-delay, - Low inlet gas pressure (if LGPS used) - Restricted vent

13 LIMIT CIRCUIT LOCKOUT - Lockout occurs if the iimit, draft safeguard, flame rottout, or If it opene during biower on-detay period, biower will come on for the selected biower

blocked vent switch (if used) is open ionger than 3 minutes, off-delay,

- Controi will auto reset after three hours, - Refer to #33, 33 LIMIT CIRCUIT FAULT - Indicates a limit, draft safeguard, flame roitout, or biocked vent

14 IGNITION LOCKOUT - Controi will auto-reset after three hours, Refer to #34, switch (if used) is open, Btower will run for 4 minutes or until open switch remakes

21 GAS HEATING LOCKOUT - Controt will NOT auto reset, whichever is longer, If open ioeger than 3 minutes, code changes to iockout #13,

Check for: - Mis-wired gas valve -Defective control (valve relay) If open tess than 3 minutes status code #33 continues to flash until blower shuts off,

22 ABNORMAL FLAME-PROVING SIGNAL - Ftame is proved while gas valve is de- Flame roHout switch and BVSS require manual reset, Check for: - Restricted vent

energized, Inducer will run unfit fautt is cleared, Check for: - Leaky gas valve - Proper vent sizing - Loose blower wheel, - Excessive wind

- Stuck-opan gas valve - Dirty fliter or restricted duct system,

23 PRESSURE SWITCH DID NOT OPEN Check for: - Defective biower motor or capacitor, - Defective switch or connections,

- Obstructed pressure tubing, - Pressure switch stuck diosed, - Inadequate combustion air suppiy (Flame Roll-out Switch open),

24 SECONDARY VOLTAGE FUSE IS OPEN Check for: 34 IGNITION PROVING FAILURE - Coetroi will try three more times before iockout #14

- Short circuit in secondary voltage (24VAC) wiring, occurs, If flame signal iost during biower on-delay period, biower wilt come on for the

selected biower off-delay, Check for: - Flame sensor must not be grounded

- Oxide buildup on flame sensor (clean with fine steel weal),

- Proper flame sense microamps (.5 microamps D.C. rain., 4.0 - 6.0 nominal),

- Gas valve defective or gas valve turned off - Manual valve shut-off

- Defective Hot Surface Ignitor - Controi ground continuity

- Low iniet gas pressure - Inadequate flame carryover or rough ignition

- Green/Yellow wire MUST be connected to furnace sheet metal

45 CONTROL CIRCUITRY LOCKOUT Auto-reset after one hour iockout due to;

- Gas valve relay stuck open - Flame sense circuit failure - Software check error

Reset power to ctear lockout, Replace controt if status code repeats,

COMPONENT TEST

To initiate the component test sequence, shut OFF the room thermostat or disconnect the "R" I

I

thermostat lead, Briefly short the TESTfTWlN terminal to the "Corn 24V" terminal, Status LED

will flash code and then turn ON the inducer motor, The inducer motor will rue for the entire I

component test, The hot surface ignitor, biower motor fan speed (on AMBER LED boards

only) b_ower motor-heat speed, and b_ower motor-coot speed witt be turned ON for 10-15 I

seconds each, Gas Valve and Humidifier wilt not be turned on,

_ 327596-101 REV. B

A04223

Fig. 55 - Service Label

45

Loading...

Loading...