32

GAS PIPING

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber. Never

test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection

of leaks to check all connections. A fire or explosion may

result causing property damage, personal injury or loss of

life.

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Use proper length of pipe to avoid stress on gas control

manifold and gas valve.

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Gas valve inlet and/or inlet pipe must remain capped until

gas supply line is permanently installed to protect the valve

from moisture and debris. Also, install a sediment trap in the

gas supply piping at the inlet to the gas valve.

!

WARNING

Gas piping must be installed in accordance with national and local

codes. Refer to current edition of NFGC in the U.S.A. Refer to

current edition of NSCNGPIC in Canada.

Installations must be made in accordance with all authorities

having jurisdiction. If possible, the gas supply line should be a

separate line running directly from meter to furnace.

NOTE: Use a back --up wrench on the inlet of the gas valve when

connecting the gas line to the gas valve.

In the State of Massachusetts:

1. Gas supply connections MUST be performed by a licensed

plumber or gas fitter.

2. When flexible connectors are used, the maximum length

shall not exceed 36 in. (915 mm).

3. When lever handle type manual equipment shutoff valves

are used, they shall be T -- handle valves.

4. The use of copper tubing for gas piping is NOT approved

by the State of Massachusetts.

NOTICE

Refer to Table 8 for recommended gas pipe sizing. Risers must be

used to connect to furnace and to meter. Support all gas piping

with appropriate straps, hangers, etc. Use a minimum of one

hanger every 6 ft. (2 M). Joint compound (pipe dope) should be

applied sparingly and only to male threads of joints. Pipe dope

must be resistant to the action of propane gas.

FIRE OR EXPLOSION HAZARD

A failure to follow this warning could result in personal

injury, death, and/or property damage.

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use a

connector which has previously served another gas

appliance. Black iron pipe shall be installed at the furnace

gas control valve and extend a minimum of 2--in. (51 mm)

outside the furnace.

!

WARNING

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in furnace damage.

Connect gas pipe to furnace using a backup wrench to

avoid damaging gas controls and burner misalignment.

CAUTION

!

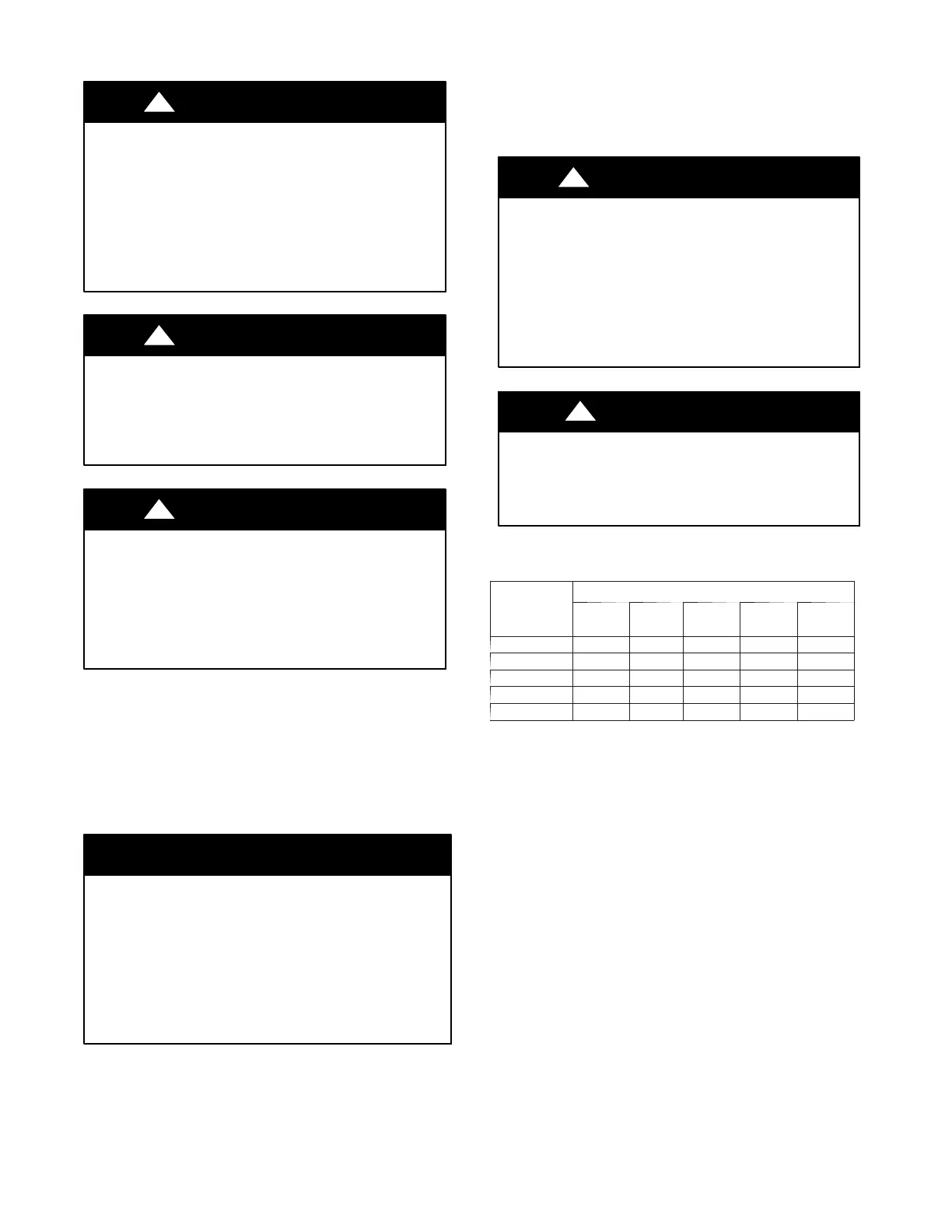

Table 8 – Maximum Capacity of Pipe

NOMINAL

IRON PIPE

SIZE

IN. (MM)

LENGTH OF PIPE --- FT (M)

10

(3.0)

20

(6.0)

30

(9.1)

40

(12.1)

50

(15.2)

1/2 (13) 175 120 97 82 73

3/4 (19) 360 250 200 170 151

1 ( 25) 680 465 375 320 285

1-1/4 (32) 1400 950 770 660 580

1-1/2 (39) 2100 1460 1180 990 900

* Cubic ft of gas per hr for gas pressures of 0.5 psig (14--- In. W.C.) or less and

a pressure drop of 0.5--- In. W.C. (based on a 0.60 specific gravity gas). Ref:

Table 8 a bove and 6.2 of the current edition NFPA54/ANSI Z223.1.

An accessible manual equipment shutoff valve MUST be installed

external to furnace casing and within 6 ft. (2 M) of furnace.

Install a sediment trap externally in the riser leading to furnace as

showninFig.30. Connect a capped nipple into lower end of tee.

Capped n ipple should extend below level of furnace gas controls.

Place a ground joint union between furnace gas control valve and

exterior manual equipment gas shutoff valve.

Loading...

Loading...