Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53300170-01 Printed in U.S.A. Form 30MP-4T Pg 1 8-17 Replaces: 30MP-3T

Controls, Start-Up, Operation,

Service, and Troubleshooting

CONTENTS

Page

SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . . . . .2,3

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Conventions Used in this Manual . . . . . . . . . . . . . . . . 3

Basic Controls Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Main Base Board (MBB). . . . . . . . . . . . . . . . . . . . . . . . . . 7

AUX Board (AUX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Energy Management Module (EMM) . . . . . . . . . . . . . . 7

Current Sensor Board (CSB) . . . . . . . . . . . . . . . . . . . . . 7

Expansion Valve (EXV) Board . . . . . . . . . . . . . . . . . . . . 7

Enable/Off/Remote Control Switch . . . . . . . . . . . . . . . 7

Emergency On/Off Switch. . . . . . . . . . . . . . . . . . . . . . . . 7

Board Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control Module Communication . . . . . . . . . . . . . . . . . 7

Carrier Comfort Network

®

Interface . . . . . . . . . . . . . 13

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

• COOLER LEAVING FLUID SENSOR

• COOLER ENTERING FLUID SENSOR

• CONDENSER LEAVING FLUID SENSOR

• CONDENSER ENTERING FLUID SENSOR

• COMPRESSOR RETURN GAS

TEMPERATURE SENSOR

• OUTDOOR-AIR TEMPERATURE SENSOR

• DUAL LEAVING WATER TEMPERATURE SENSOR

• DISCHARGE TEMPERATURE THERMISTOR

• SPACE TEMPERATURE SENSOR

Energy Management Module . . . . . . . . . . . . . . . . . . . . 16

Loss-of-Cooler Flow Protection . . . . . . . . . . . . . . . . . 16

Condenser Flow Protection . . . . . . . . . . . . . . . . . . . . . 16

Thermostatic Expansion Valves (TXV) . . . . . . . . . . 16

Electronic Expansion Valves (EXV) . . . . . . . . . . . . . 17

Capacity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

• MINUTES LEFT FOR START

• MINUTES OFF TIME

• CAPACITY CONTROL OVERRIDES

Time, Day, and Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operation of Machine Based on Control Method. . 21

Cooling Set Point Select . . . . . . . . . . . . . . . . . . . . . . . . 25

Ice Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cooler Pump Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Alarm Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cooler Pump Sequence of Operation . . . . . . . . . . . 27

Condenser Pump/Condenser Fan Output

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Configuring and Operating Dual Chiller Control. . 27

Temperature Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Demand Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

• DEMAND LIMIT (2-Stage Switch Controlled)

• EXTERNALLY POWERED DEMAND LIMIT

(4 to 20 mA Controlled)

• DEMAND LIMIT (CCN Loadshed Controlled)

Cooling Set Point (4 to 20 mA) . . . . . . . . . . . . . . . . . . 34

Page

Digital Scroll Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36,37

System Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

START-UP AND OPERATION. . . . . . . . . . . . . . . . . 37-40

Actual Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Check Refrigerant Charge. . . . . . . . . . . . . . . . . . . . . . . 38

Check Compressor Oil Level. . . . . . . . . . . . . . . . . . . . 39

Adjust Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operating Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

• TEMPERATURES

• VOLTAGE — ALL UNITS

OPERATION SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . 40

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-52

Service Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Electronic Components . . . . . . . . . . . . . . . . . . . . . . . . . 41

• CONTROL COMPONENTS

Electronic Expansion Valve (EXV). . . . . . . . . . . . . . . 41

EXV Troubleshooting Procedure . . . . . . . . . . . . . . . . 42

Compressor Replacement . . . . . . . . . . . . . . . . . . . . . . 44

30MP Cooler and 30MPW Condenser . . . . . . . . . . . 44

• BRAZED-PLATE COOLER AND CONDENSER

HEAT EXCHANGER REPLACEMENT

• BRAZED-PLATE COOLER AND CONDENSER

HEAT EXCHANGER CLEANING

Water Treatment . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Check Refrigerant Feed Components . . . . . . . . . . . 45

• FILTER DRIER

• MOISTURE-LIQUID INDICATOR

• THERMOSTATIC EXPANSION VALVE (TXV)

• MINIMUM LOAD VALVE

• PRESSURE RELIEF DEVICES

Check Unit Safeties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Thermistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Pressure Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chilled Water Flow Switch . . . . . . . . . . . . . . . . . . . . . . 47

Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Replacing Defective Modules . . . . . . . . . . . . . . . . . . . 52

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Recommended Maintenance Schedule. . . . . . . . . . 52

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 52-71

Complete Unit Stoppage and Restart. . . . . . . . . . . . 52

• GENERAL POWER FAILURE

• UNIT ENABLE-OFF-REMOTE CONTROL SWITCH

IS OFF

• CHILLED FLUID PROOF-OF-FLOW SWITCH OPEN

• OPEN 24-V CONTROL CIRCUIT BREAKER(S)

• COOLING LOAD SATISFIED

• THERMISTOR FAILURE

• ENABLING AND DISABLING COMPRESSORS

• COMPRESSOR DISCHARGE CHECK VALVE

• LOW SATURATED SUCTION

• COMPRESSOR SAFETIES

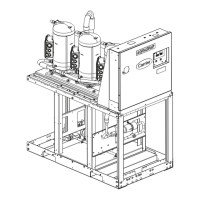

AquaSnap

®

30MPA,MPW015-071

Liquid Chillers with Scroll Compressors

and ComfortLink Controls

Loading...

Loading...