61

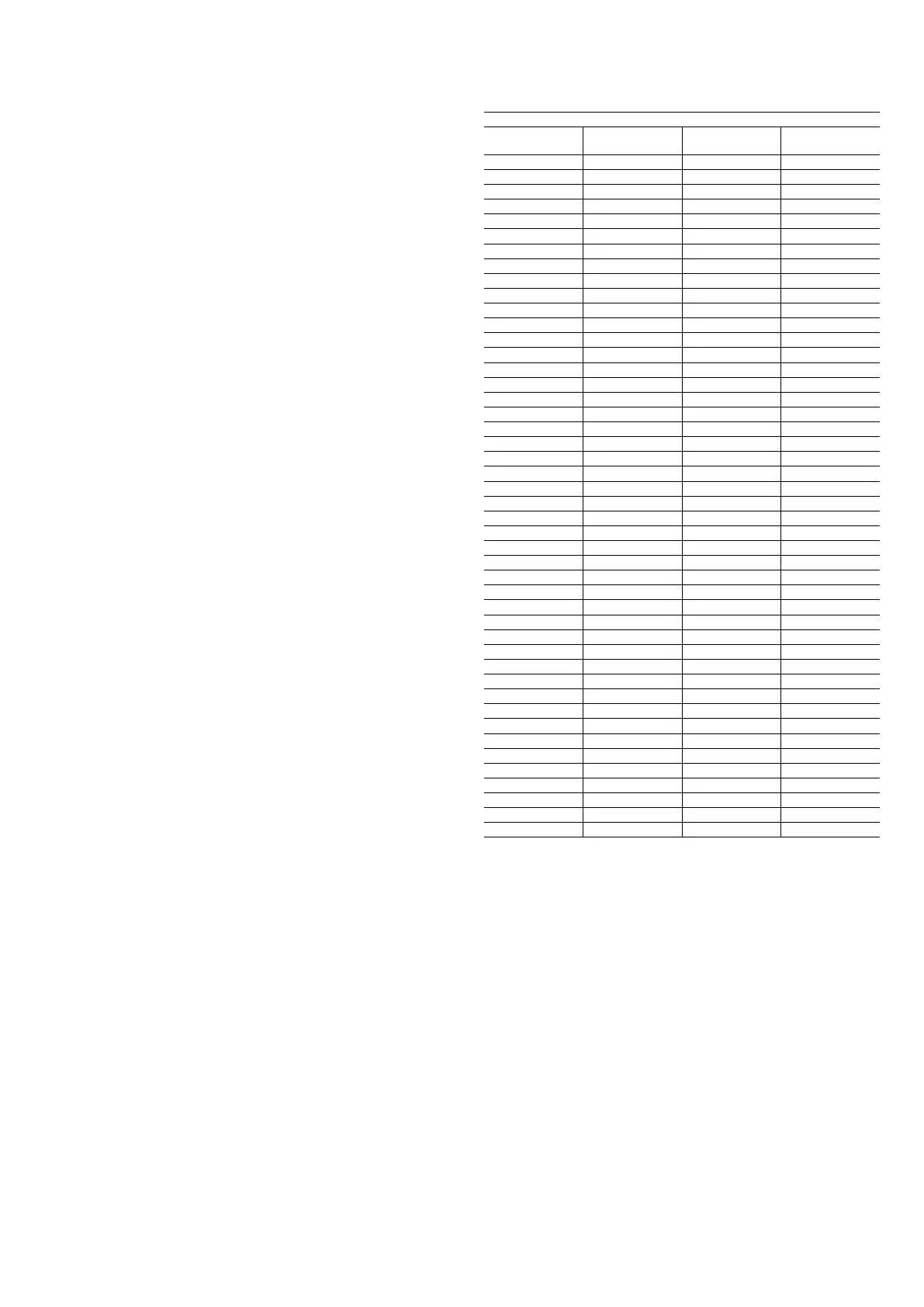

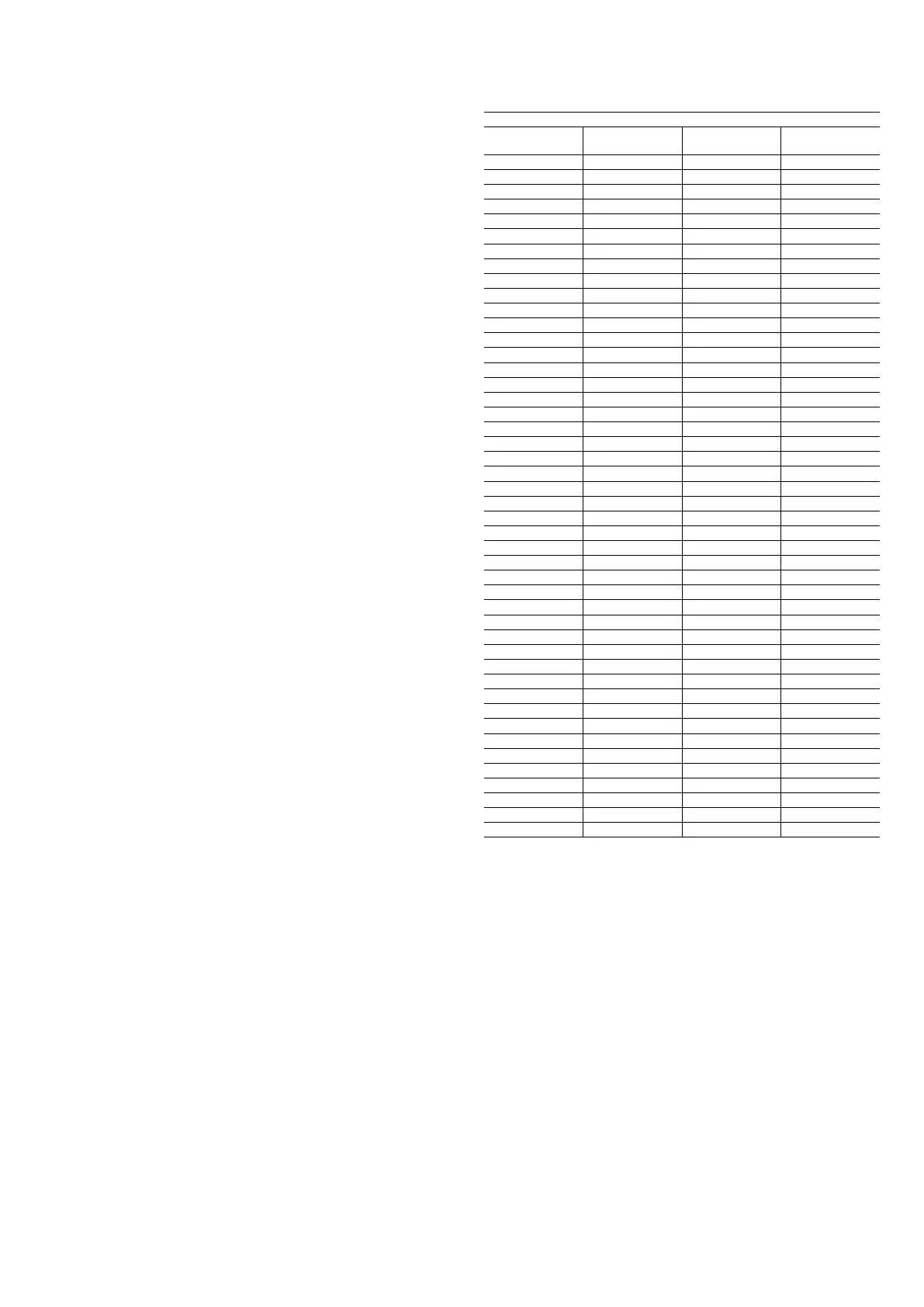

See the table below.

-20 297 25 1552

-19 312 26 1596

-18 328 27 1641

-17 345 28 1687

-16 361 29 1734

-15 379 30 1781

-14 397 31 1830

-13 415 32 1880

-12 434 33 1930

-11 453 34 1981

-10 473 35 2034

-9 493 36 2087

-8 514 37 2142

-7 535 38 2197

-6 557 39 2253

-5 579 40 2311

-4 602 41 2369

-3 626 42 2429

-2 650 43 2490

-1 674 44 2551

0 700 45 2614

1 726 46 2678

2 752 47 2744

3 779 48 2810

4 807 49 2878

5 835 50 2947

6 864 51 3017

7 894 52 3088

8 924 53 3161

9 956 54 3234

10 987 55 3310

11 1020 56 3386

12 1053 57 3464

13 1087 58 3543

14 1121 59 3624

15 1156 60 3706

16 1192 61 3789

17 1229 62 3874

18 1267 63 3961

19 1305 64 4049

20 1344 65 4138

21 1384 66 4229

22 1425 67 4322

23 1467 68 4416

24 1509 69 4512

70 4610

Aquasnap Puron units use high-pressure R-410A refrigerant

(the unit operating pressure is above 40 bar, the pressure

at 35°C air temperature is 50% higher than for R-22).

Special equipment must be used when working on the

refrigerant circuit (pressure gauge, charge transfer, etc.).

Level 2

The two cleaning products can be used for any of the

following coil finishes: Cu/Cu, Cu/Al, Cu/Al with Polual,

Blygold and/or Heresite protection.

Clean the coil, using appropriate products.

We recommend TOTALINE products for coil cleaning:

Part No. P902 DT 05EE: traditional cleaning method

Part No. P902 CL 05EE: cleaning and degreasing.

These products have a neutral pH value, do not contain

phosphates, are not harmful to the human body, and can

be disposed of through the public drainage system.

Depending on the degree of fouling both products can be

used diluted or undiluted.

For normal maintenance routines we recommend using 1 kg

of the concentrated product, diluted to 10%, to treat a coil

surface of 2 m

2

. This process can either be carried out using

a high-pressure spray gun in the low-pressure position. With

pressurised cleaning methods care should be taken not to

damage the coil fins. The spraying of the coil must be done:

- in the direction of the fins

- in the opposite direction of the air flow direction

- with a large diffuser (25-30°)

- at a minimum distance of 300 mm from the coil.

It is not necessary to rinse the coil, as the products used

are pH neutral. To ensure that the coil is perfectly clean, we

recommend rinsing with a low water flow rate. The pH

value of the water used should be between 7 and 8.

For MCHX condenser coils use only clean water with a pH

value between 7 and 8.

WARNING: Never use pressurised water without a large

diffuser. Do not use high-pressure cleaners for Cu/Cu and

Cu/Al coils! High pressure cleaners are only permitted

for MCHX coils (maximum permitted pressure 62 bar).

Concentrated and/or rotating water jets are strictly

forbidden. Never use a fluid with a temperature above

45°C to clean the air heat exchangers.

Correct and frequent cleaning (approximately every three

months) will prevent 2/3 of the corrosion problems.

Protect the control box during cleaning operations.

Check that:

• the insulating foam is intact and securely in place.

• the cooler heaters are operating, secure and correctly

positioned.

• the water-side connections are clean and show no sign

of leakage.

Loading...

Loading...