3

Step 4.— Connect Ducts to ERV/HRV

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in minor

property damage from sweating duct or loss of unit

efficiency and capacity .

If ERV/HRV duct work is installed in an unconditioned

space, insulated flexible duct is required.

CAUTION

!

Insulated flexible duct is required on both fresh-- air inlet and

exhaust--air outlet ducts connecting to exterior wall. When using

insulated flexible duct, the vapor barrier of the flexible ducts must

be taped very tight to prevent condensation problems. To reduce

pressuredrop, stretch the flex duct and support it in a proper manner

to avoid reduced airflow.

When connecting the ERV/HRV to a return--air duct system,

insulated flexible duct can be used. However, when metal or rigid

ducts are applied use approximately 18--in. of flexible duct at

ERV/HRV ports for fresh--air supply, and stale-- air return. When

using metal duct from fresh--air supply to system duct work, the

metal duct should be insulated (See Fig. 5).This can act as a silencer

when connecting ducts to return-- air duct system. This should

eliminate transmission of noise or vibration from unit to main duct

system.

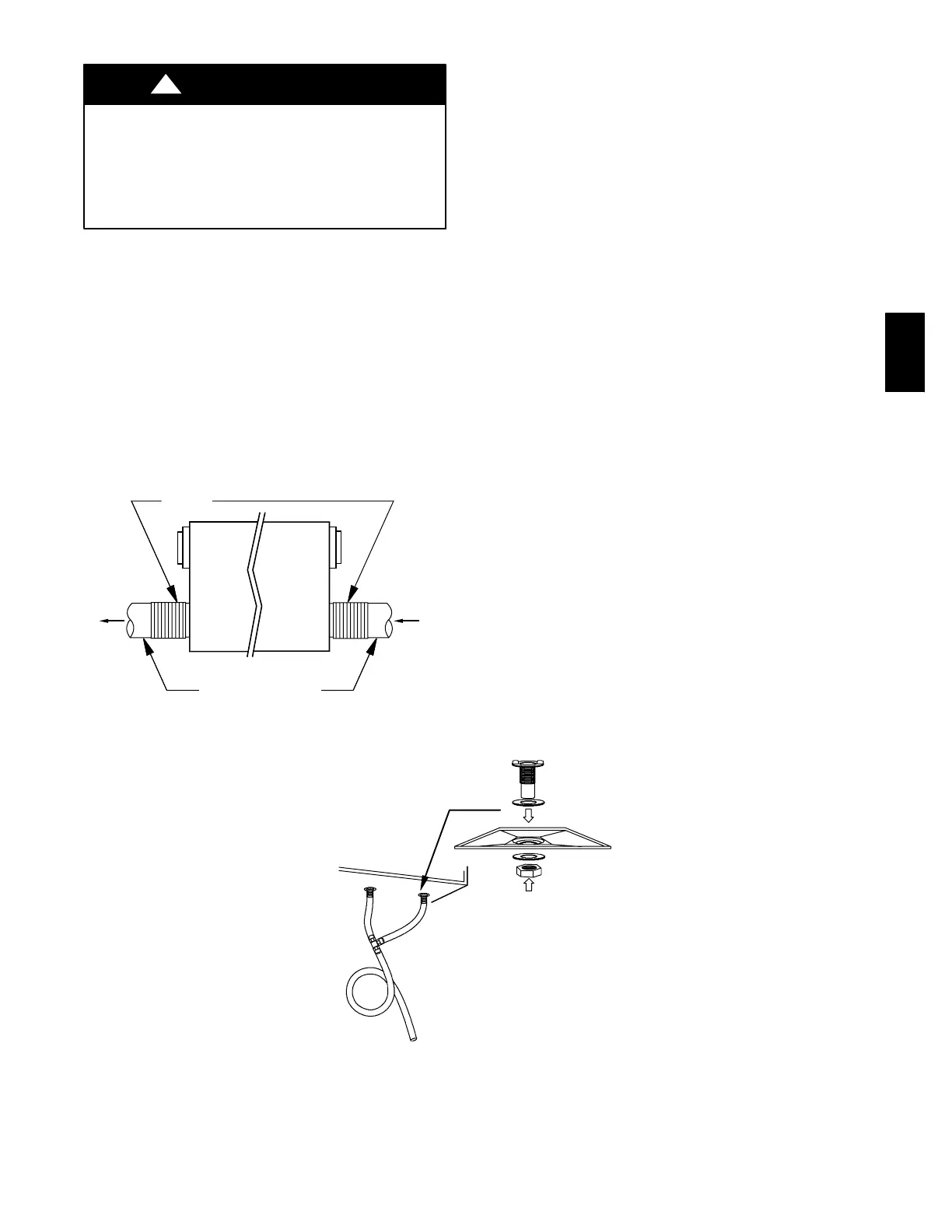

FLEXIBLE

DUCT

FRESH-AIR

SUPPLY

STALE-AIR

RETURN

DUCTS CONNECTING TO

RETURN-AIR DUCT SYSTEM

A98382

Fig. 5 -- Flexible Duct Fit--Up

Step 5.—Locate and Install Exterior Hoods

IMPORTANT: To prevent condensation problems, insulated

flexible ducts are required on both fresh -- air inlet and exhaust--air

outlet ducts connecting between ERV/HRV and exterior wall.

Fresh--air intake and stale--air exhaust must be separated by at least

6 ft. Fresh--air intake must be positioned at least 10 ft. from nearest

dryer vent, furnace exhaust, driveway, gas meter, or oil fill pipe.

Fresh--air intake must be positioned as far as possible from garbage

containers and potential chemical fumes. When possible, it is

advised tolocatetheintake and exhaust hoodson sameside of house

or building. The intake and exhaust hoods should never be located

on interior corners or in dead air pockets (See Fig. 7). Both intake

and exhaust hoods must be 18 in. from ground and at least 12 in.

above anticipated snow level.

After selecting proper hood locations, make appropriate size hole

through exterior wall, pass flexible duct through hole and insert

hood tube into duct. Tape duct vapor barrier tightly around hood

tube and insert assembly back into wall and fasten securely.

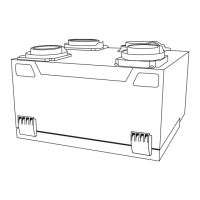

Step 6.—Condensate Drain

(For ERV, skip Step 6 and continue to Step 7.)

To connect condensate drain, proceed as follows:

1. Punch out holes in foam insulation and door, then insert

sleeved grommets into bottom of unit using the gasket

washer and nut (See Fig. 6).

2. Cut two sections of plastic tubing,about 12” long and attach

them to each drain.

3. Join the two short sections of plastic tubing to the “T”

connector and the main tube as shown.

4. Make a loop in the tubing below the “T” connector to create

a trap to prevent sewer gases from entering the ventilation

system (See Fig. 6).

5. Connect unit drain to building’s main drain. Provide slight

slope from unit for run--off.

A99268

Fig. 6 -- Condensate Drain With Loop Trap (HRV Only)

ERV/HRV

Loading...

Loading...