17

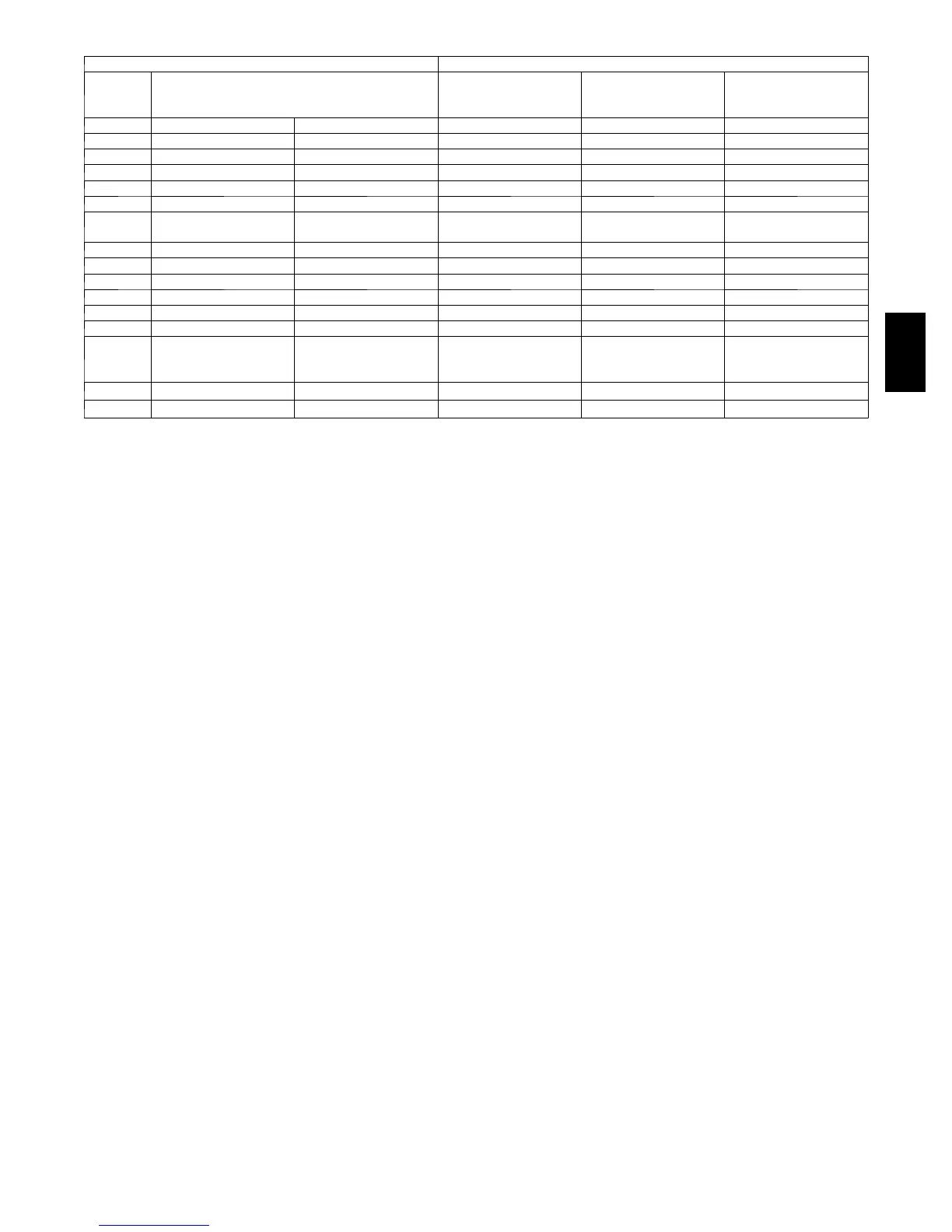

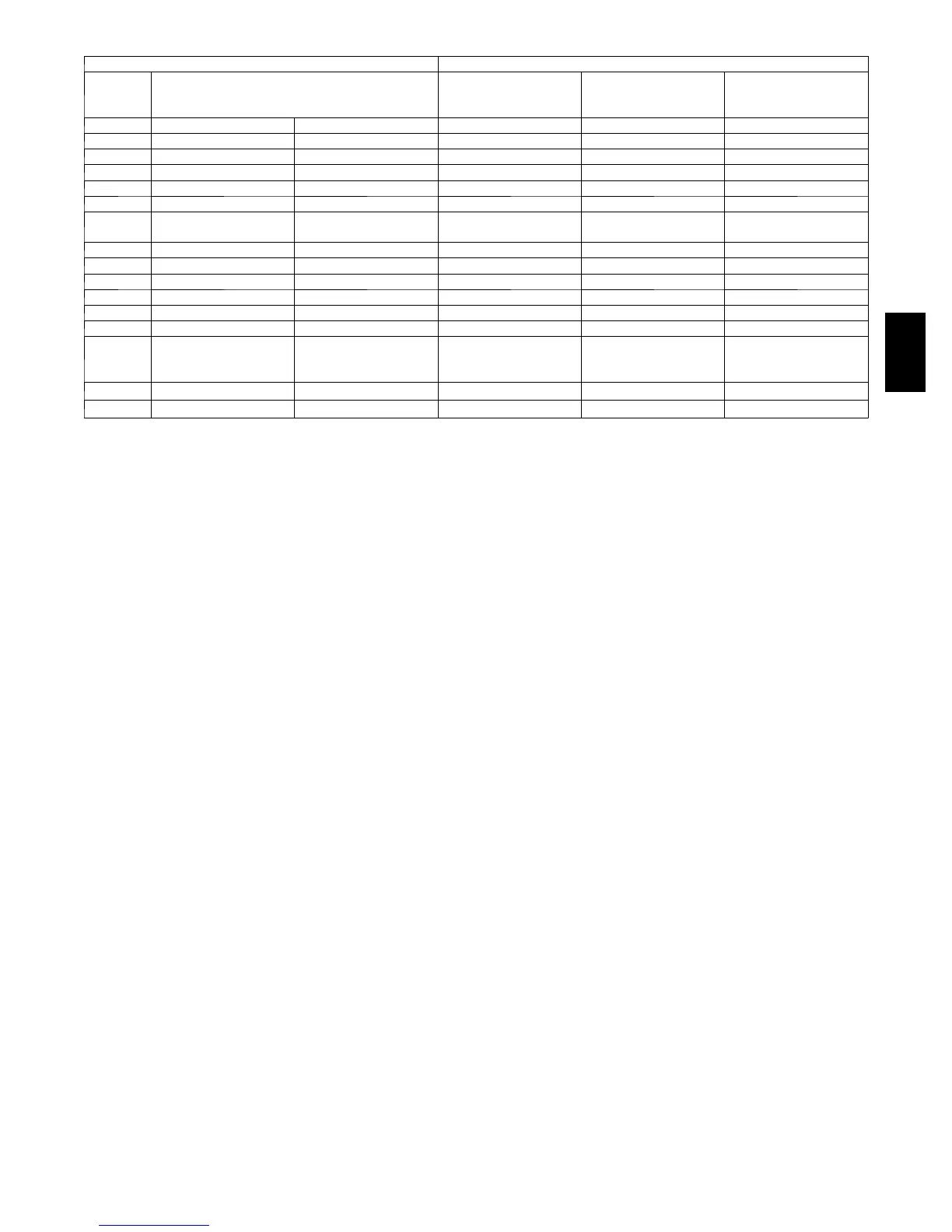

Table 7 – Wiring connection of FV Fan Coil Wiring Harness

16---IN PLUG ON WIRING HARNESS TO MOTOR WIRING HARNESS CONNECTION TO EASY SELECT BOARD

Pin on

1 6 --- P i n

Plug

Description

Pinon12---PinPlugor

Set---up Selection

Wire Color

Signal on Pin with

Screw Terminal

Jumpered to R *

1 Common Pin 9 on PL---1 Brown

2 W1 Pin 7 on PL---1 Violet 24V AC**

3 Common Auxiliary Heat Stage 1 Pin10onPL---1 Orange

4 On/Off Delay Selection On/Off Delay Selection White

5 AC/HP Size Selection AC/HP Size Selection Blue

6 Y1 Low Speed AC or HP Pin 3 on PL--- 1 Black ( --- ) 1 2 V D C * *

7

AC/HP CFM Adjust

Selection

AC/HP CFM Adjust

Selection

Black

8 Not Used N/A Not Used

9 System Type Selection System Type Selection Orange

10 Dehumidify Pin12onPL---1 Gray 0V (24VAC on no call)

11 Aux Heat Size Selection Aux Heat Size Selection Violet

12 24v AC Pin 8 on PL---1 Red 24VAC continuous

13 W2 Auxiliary Heat Stage 2 Pin 4 on PL---1 White 24V AC**

14 Y/Y2

Single Speed AC or HP,

High Speed 2---Speed

AC or HP

Pin 2 on PL---1 Y ellow ( --- ) 1 2 V D C *

15 G Fan Pin 1 on PL---1 Green 24V AC**

16 Not Used N/A Not Used

* Check voltages with 16---Pin Plug disconnected from motor.

** These signals will start motor.

PURONR (R--410A) QUICK REFERENCE GUIDE

S Puron refrigerant operates at 50--70 percent higher pressures than R--22. Be sure that servicing equipment and replacement

components are designed to operate with Puron

S Puron refrigerant cylinders are rose colored.

S Recovery cylinder service pressure rating must be 400 psig, DOT 4BA400 or DOT BW400.

S Puron systems should be charged with liquid refrigerant. Use a commercial type metering device in the manifold hose when

charging into suction line with compressor operating

S Manifold sets should be 700 psig high side and 180 psig low side with 550 psig low--side retard.

S Use hoses with 700 psig service pressure rating.

S Leak detectors should be designed to detect HFC refrigerant.

S Puron, as with other HFCs, is only compatible with POE oils.

S Vacuum pumps will not remove moisture from oil.

S Do not use liquid--line filter driers with rated working pressures less than 600 psig.

S Do not leave Puron suction line filter driers in line longer than 72 hours.

S Do not install a suction--line filter drier in liquid line.

S POE oils absorb moisture rapidly. Do not expose oil to atmosphere.

S POE oils may cause damage to certain plastics and roofing materials.

S W rap all filter driers and service valves with wet cloth when brazing.

S A factory approved liquid--line filter drier is required on every unit.

S Do NOT use an R--22 TXV.

S If indoor unit is equipped with an R--22 TXV or piston metering device, it must be changed to a hard shutoff Puron TXV.

S Never open system to atmosphere while it is under a vacuum.

S When system must be opened for service, recover refrigerant, evacuate then break vacuum with dry nitrogen and replace filter

driers. Evacuate to 500 microns prior to recharging.

S Do not vent Puron into the atmosphere.

S Do not use capillary tube coils.

S Observe all warnings, cautions,andbold text.

S All indoor coils must be installed with a hard shutoff Puron TXV metering device.

FV4C

Loading...

Loading...