17

A150195

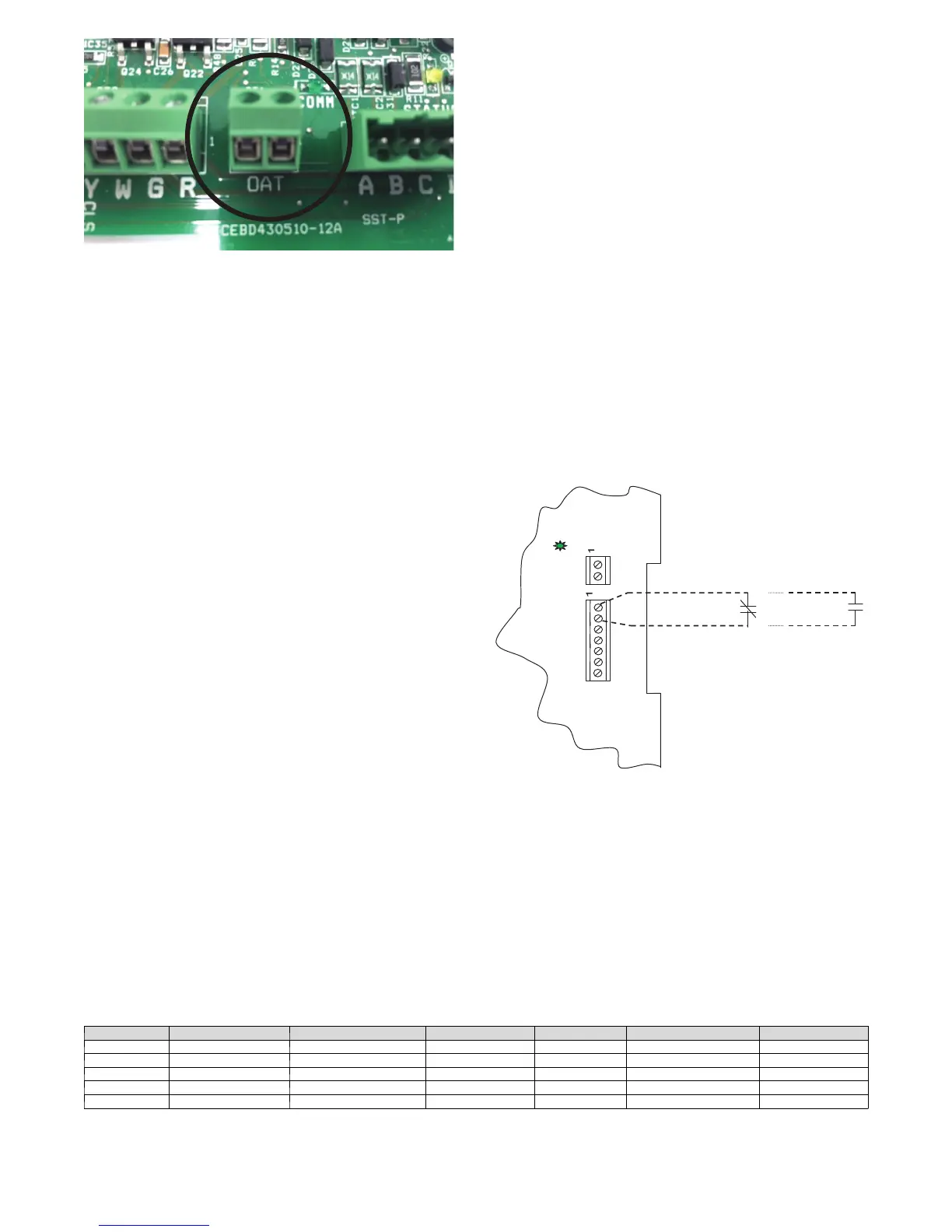

Fig. 20 -- OAT Sensor Connection

Outdoor Air Thermistor

A 2 -- screw terminal strip is provided for connection of an outdoor

temperature thermistor. The installation of an outdoor temperature

sensor using the ECM board terminals is optional. OAT input can

be used to supply outdoor temperature data for system level

functions and for temperature display on User Interface. If an OAT

is added, it will be used for system level functions.

Using two wires of field--supplied thermostat wire cable, wire one

lead of thermistor to one screw terminal and the other lead to

remaining screw terminal; there is no polarity to be observed. It is

strongly recommended that two wires be used to connect the

thermistor to eliminate noise interference in temperature reading. If

there are not two spare wires available in cable, one wire may be

used to connect thermistor to OAT screw terminal 1 and the other

lead of the thermistor can be wired to 24VAC COM (C) wire. OAT

screw terminal 1 is terminal located closest to the ABCD system

communications and is marked with a small number 1 next to the

terminal strip.

NOTE: Mis--wiring OAT inputs will not cause damage to either

ECM board or thermistor. If the thermistor is wired incorrectly, no

reading will appear at User Interface. Re--wire thermistor correctly

for normal operation.

Electronic Air Cleaner Connections

When using an electronic air cleaner, use airflow sensor part no.

KEAAC0101AAA. The airflow sensor turns on electronic air

cleaner when blower is operating.

Humidifier Connections

The ECM board terminal marked “HUM” is provided for low

voltage (24VAC) control of a humidifier. No humidistat is required

as User Interface monitors indoor humidity. When commanded to

operate humidifier, the ECM board will ener gize the “HUM”

output to turn humidifier on and de-- energize HUM output to turn

humidifier off. Wire “HUM” and “C” terminals directly to

humidifier as shown in Fig. 18 or 19.

System Shutdown Accessories

The G thermostat terminal input can be configured through the

User Interface to recognize accessories that will shut the system

down in response to a malfunction. The ECM board can be

configured to recognize either Normally Open or Normally Closed

(default) contact devices through the User Interface Set-- Up

screens. Wire the accessory device contacts in series with the R and

G thermostat connections at the ECM board board. The User

Interface will respond to the accessory device signal by ordering a

shutdown of the system and will display SYSTEM

MALFUNCTION on its screen. Refer to the User Interface

Installation Instructions for more detail. See Fig. 21.

Generator

The ECM board G thermostat terminal input can be configured

through the User Interface to recognize a Generator Normally

Open dry-- contact output to signal the system that a generator

malfunction condition exists. Wire the generator output in series

with the R and G thermostat connections at the ECM board. The

User Interface will display GENERATOR MALFUNCTION when

the G thermostat input is energized. This function requires the

addition of a Generator Self Test Verifier (Part No. GSV200) which

must be purchased separately. V isit www.GeneratorVerifier.com for

details and ordering information. Refer to the User Interface

Installation Instructions for more detail. See Fig. 21.

Ventilation Accessory

The G thermostat terminal input can be configured through the

User Interface to recognize a Normally Open dry--contact output to

signal the system that a Ventilation Accessory requires blower

operation. Blower operation can be configured for Low, Med or

High speed when the G terminal is ener gized. Wire the Accessory

output in series with the R and G thermostat connections at the

ECM board. Refer to the User Interface Installation Instructions for

more detail. See Fig. 21.

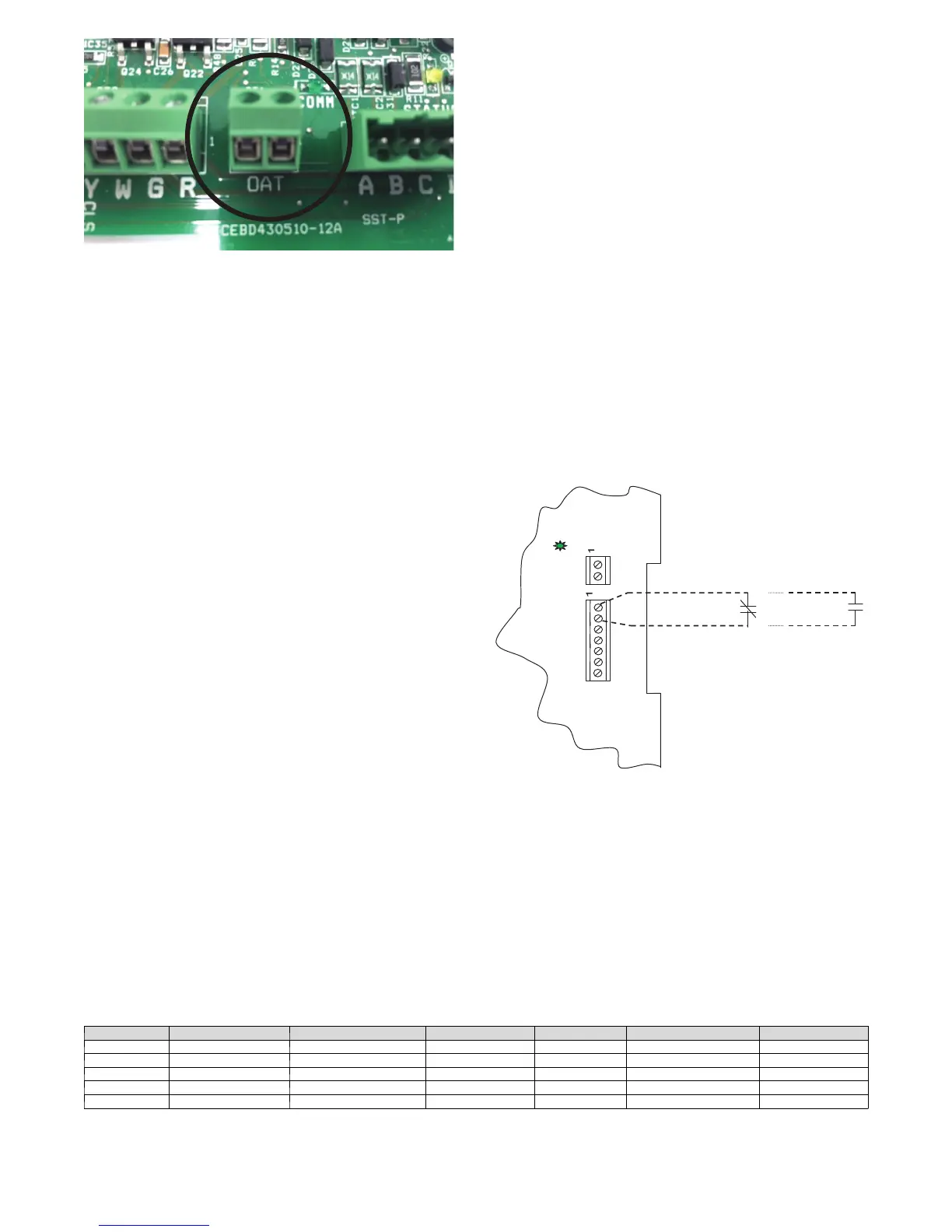

COMM

OAT

HUM C O Y W G R

CLS

OPN

COM

System

Shutdown

Device

System

Shutdown

Device

or

Generator

or

VentilationAccessor

A07121

Fig. 21 -- “G” Terminal Accessory Wiring

Compressor Start Accessories

In the event of the rare occurrence of compressor starting issues

such as dimming of the residential lights. Verify and correct

voltage issues and add hard start components. Table 7 lists Hard

Start components that are recommended in areas of poor power

conditions.

Table 7 – Recommended Hard Start Kits

Unit Size Compressor Hard Start Kit Start Cap Start MFD Start Cap Volts Start Relay

GC024 ZPS20K5E ---PFV KSAHS2501AAA HC95DE088 88---108 330 HN61HB540

GC036 ZPS30K5E ---PFV KSAHS2501AAA HC95DE088 88---108 330 HN61HB540

GC048 ZPS40K5E ---PFV KSAHS2801AAA HC95DE088 88---108 330 HN61HB553

GC060 ZPS51K5E ---PFV KSAHS2801AAA HC95DE088 88---108 330 HN61HB553

GC072 ZPS60K5E ---PFV N/A N/A 43 330 HN61HB553

Loading...

Loading...