23

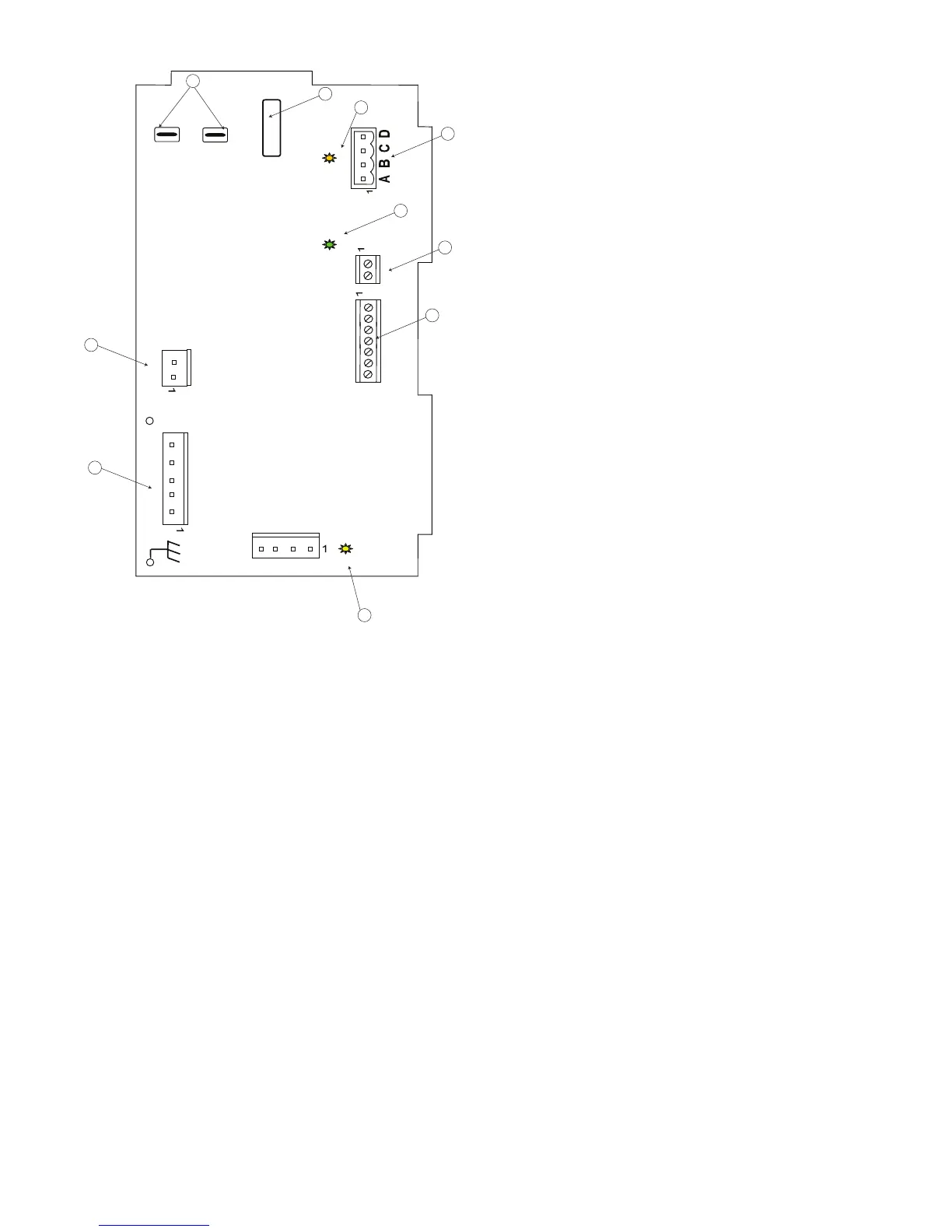

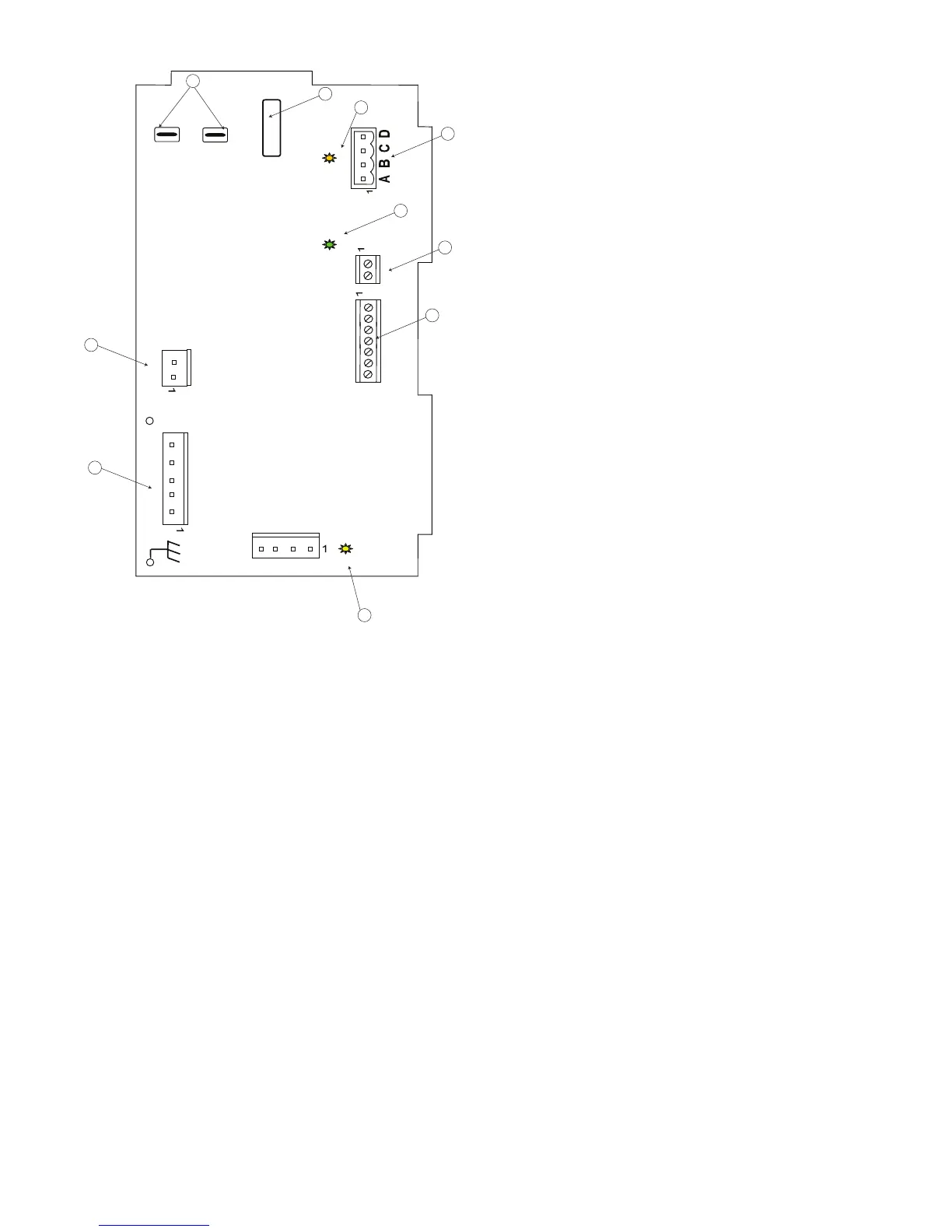

ECM BOARD

SEC-1

SEC-2

FUSE 3AMP

HEATER

STATUS

COMM

OAT

MOTOR

HPT

HUM C O Y W G R

OPN

COM

CLS

1

2

3

4

5

6

7

8

10

11

A150556

(1) SEC 1 and SEC 2 (7) Non--comm. t--stat emergency only

connections

(2) Transformer Power (8) Motor Power Indicator Light

(3) Status LED Light (9)

(4) ABCD Communicating Thermostat

Terminal Plug Connection.

(10) Heater Connection f or Field

Supply Electric Heat

(5) COMM Light (11) HPT

(6) OAT -- Outdoor Air Temp Sensor

Fig. 28 -- Detail of ECM Printed Circuit Board Connections

NOTE: CFM LED indication is an approximation. Utilize

conventional Test and Balance equipment for accurate airflow

measurement.

SCFM count indicator (see Fig. 28, item 6) blinks to indicate

approximate airflow in CFM and may flicker when the unit is off.

SEach blink of the LED represent approximately 100 CFM of air

delivery so if the LED blinks 12 times, pauses, blinks 12 times, etc.

the blower is delivering approximately 1200 CFM.

SAn annual “checkup” is recommended by a qualified refrigeration

mechanic.

SRecording the performance measurements of volts, amps, and water

temperature differences (both heating and cooling) is recommended.

This data should be compared to the information on the unit’s data

plate and the data taken at the original start-- up of the equipment.

SPeriodic lockouts are commonly caused by water flow problems.

The lockout (shutdown) of the unit is a normal protective measure in

the design of the equipment. If continual lockouts occur, call a

mechanic immediately and have them check for the following:

-- Water flow problems

-- Water temperature problems

Unit capacity and water flow charts should be used for system

checks. Refer to Table 9.

Using the Owner’s/User Manual furnished with unit, the installing

technician should explain system operation to the consumer with

particular emphasis on indoor fan coil operation sounds and filter

maintenance.

ECM Sequence of Operation

The GC is designed for installation with a communicating User

Interface. This blower will not respond to commands provided by a

common thermostat except under certain emergency situations

described in Blower Start Up and Troubleshooting section of this

document.

The User Interface uses temperature; humidity and other data

supplied from system components to control heating or cooling

system for optimum comfort. The blower will be commanded by

User Interface to supply airflow. The blower will operate at

requested airflow for most modes.

The nominal requested airflow will be 350 cfm per ton of nominal

cooling capacity as defined by unit size. Actual airflow request will

be adjusted from nominal using indoor and outdoor temperature

and indoor humidity data to optimize the system operation for

occupant comfort and system efficiency. Refer to User Interface

literature for further system control details.

Airflow during electric heater operation must be greater than a

minimum level for safe operation. If User Interface instructs blower

to turn on electric heat and the requested airflow is less than the

minimum value required for safe operation of installed heater, the

ECM board will override requested value with the value shown in

Table 10, Blower Airflow Delivery Chart -- Electric Heating

Modes.

Loading...

Loading...