Carver Inc 5-1

SECTION FIVE MAINTENANCE

Each CARVER Laboratory Press is thoroughly tested to provide trouble-free performance. Manufacturing and

assembly processes are closely controlled in our factory under rigid inspection and testing procedures. Follow these

instructions, and with proper care, your press should give many years of trouble-free service.

5.1 TROUBLESHOOTING

To maintain constant pressure, the hydraulic unit may require occasional pumping, especially when pressing against a

soft or yielding material. If the pressure drops slowly as shown on the gauge, it should be considered normal. If you are

experiencing problems with the operation of your hydraulic unit, it may be due to any of the following reasons:

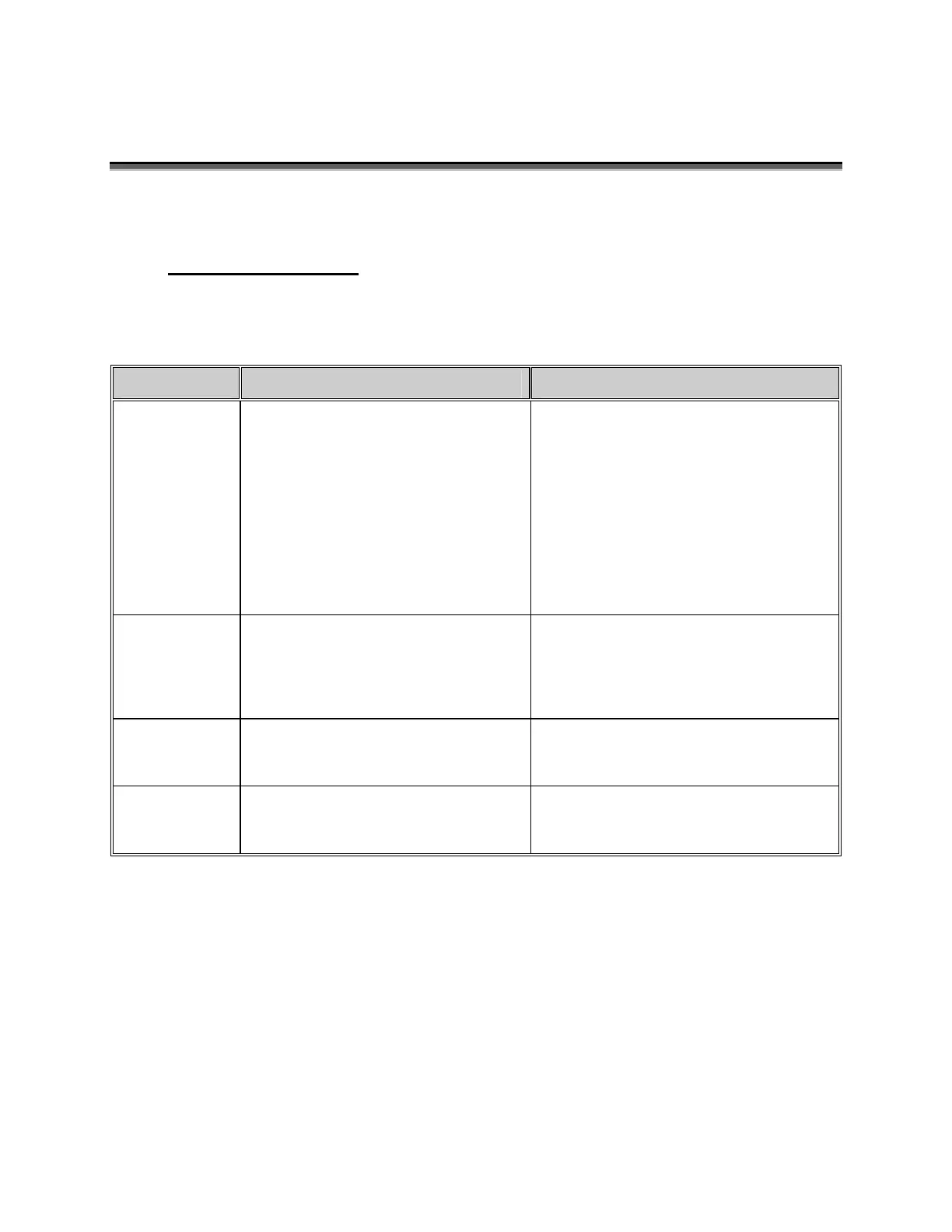

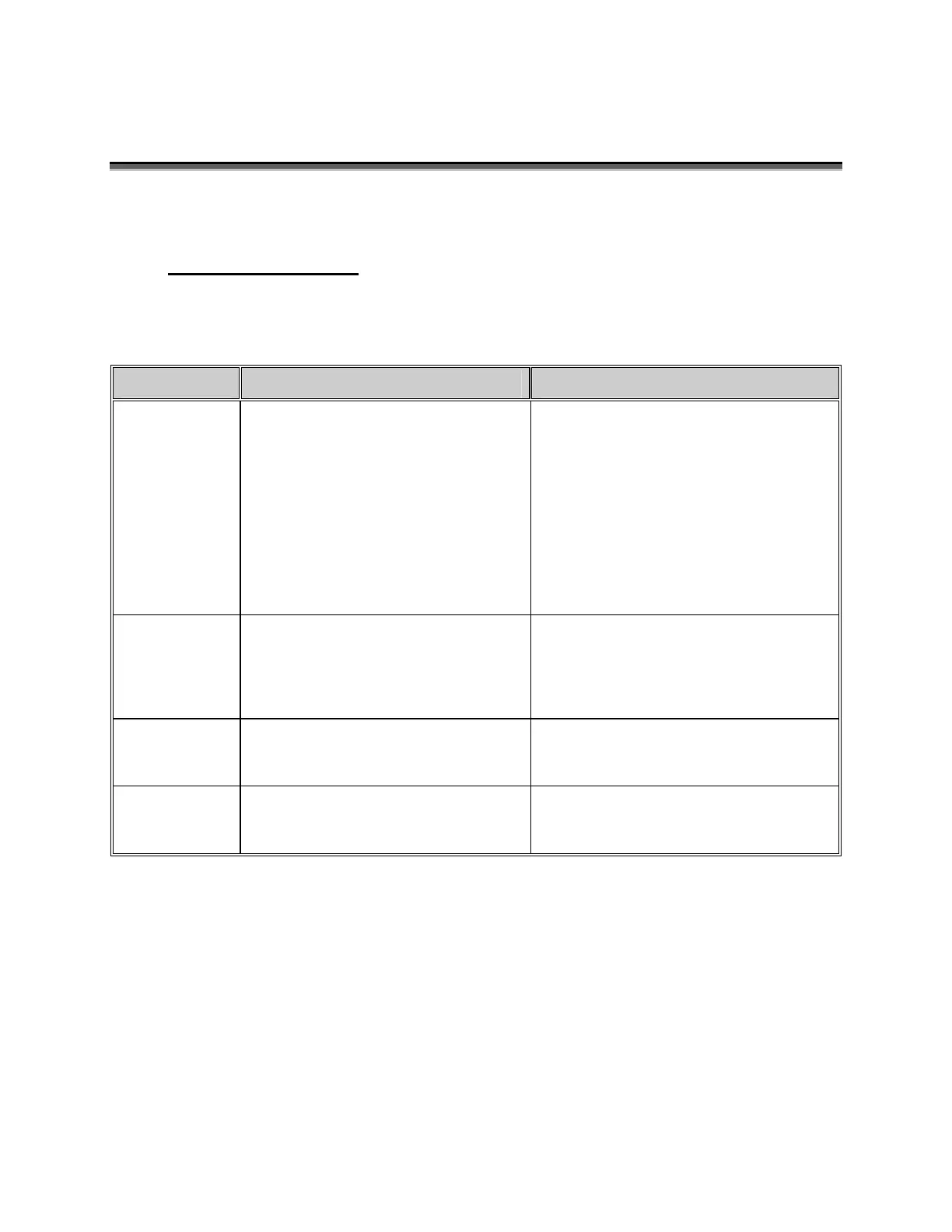

PROBLEM POSSIBLE CAUSE SOLUTION

Rapid drop in

pressure

a) Low oil level due to leakage.

b) Open release valve.

c) Worn or dislodged internal packing.

d) Dirty valve seat.

e) Air entrapment.

a) Tighten hydraulic connections and

refill with oil.

b) Close release valve.

c) Replace packing or seals where

necessary.

d) Remove release valve & clean valve

seat. Hydraulic unit may require

flushing with solvent, such as agitene.

e) Purge air from system (see Air Bleed

Procedure in Section 5).

No pressure when

pumping

a) Open release valve.

b) Worn packing in pump.

c) Release valve ball missing.

d) Release valve contaminated.

a) Close release valve.

b) Replace or rebuild hydraulic unit

pump.

c) Replace ball.

d) Remove and clean.

Slow drop in

pressure

a) Open release valve

b) Worn release valve seat.

c) Worn ram seal

a) Close release valve.

b) Contact factory for replacement.

c) Replace ram seal.

Oil leakage in

gauge coupling

a) Loose gauge fitting.

b) Gauge not sealing.

a) Tighten gauge fitting.

b) Add copper gauge seal (maximum of

two)

NOTE: Refer to the exploded view drawing accompanying this manual for the location of seals, packing, and gaskets

in the hydraulic unit.

Loading...

Loading...