11-6

AIR BLEEDING

Air accumulation in a hydraulic system will cause erratic action. This may appear as pump failure to the inexperienced

user. For this reason, it is advisable to air bleed each pump before attempting to operate. To remove air from the pump,

open release valve with the pump in an upright position. Operate the pump slowly through the full piston stroke about a

dozen times. Close the release valve. Pump should be ready for use.

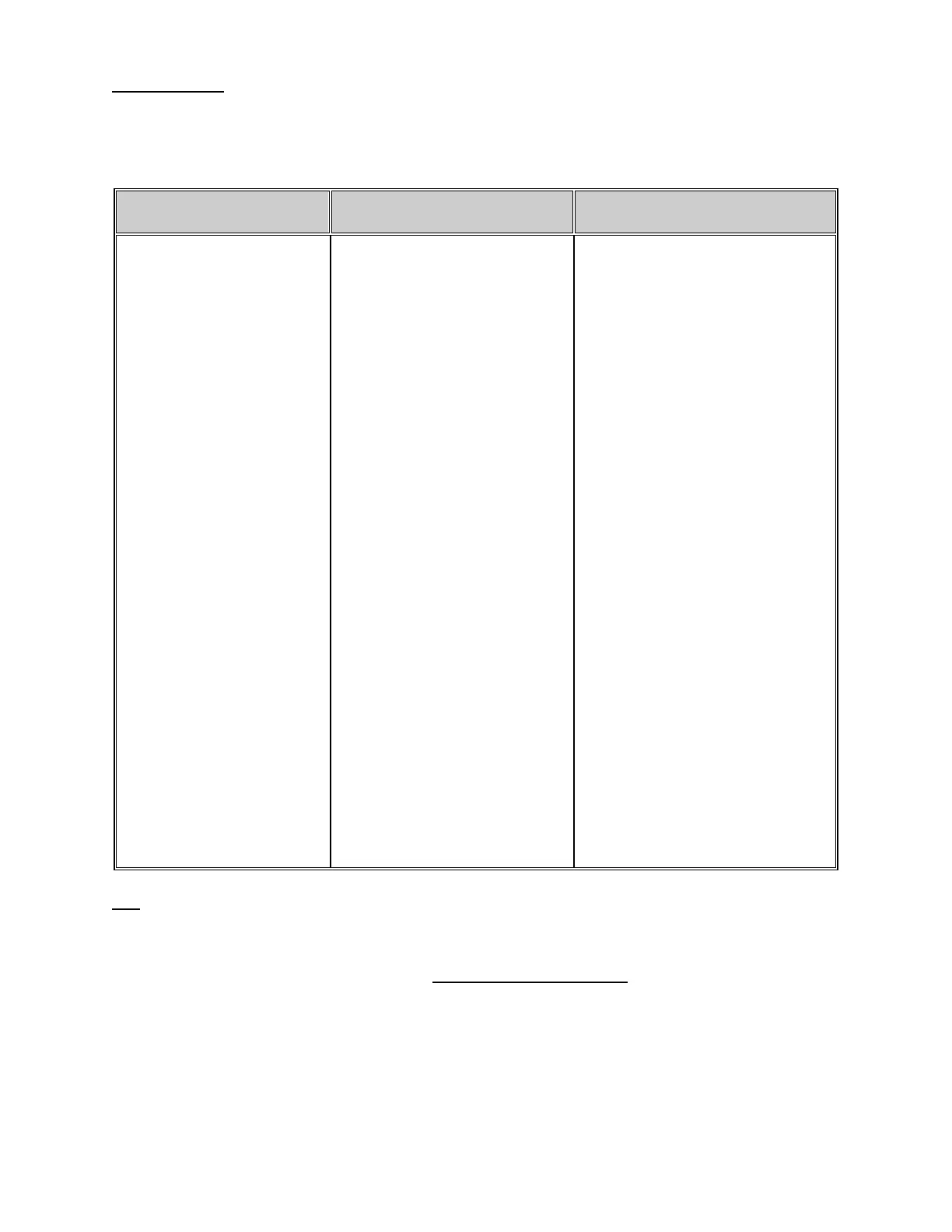

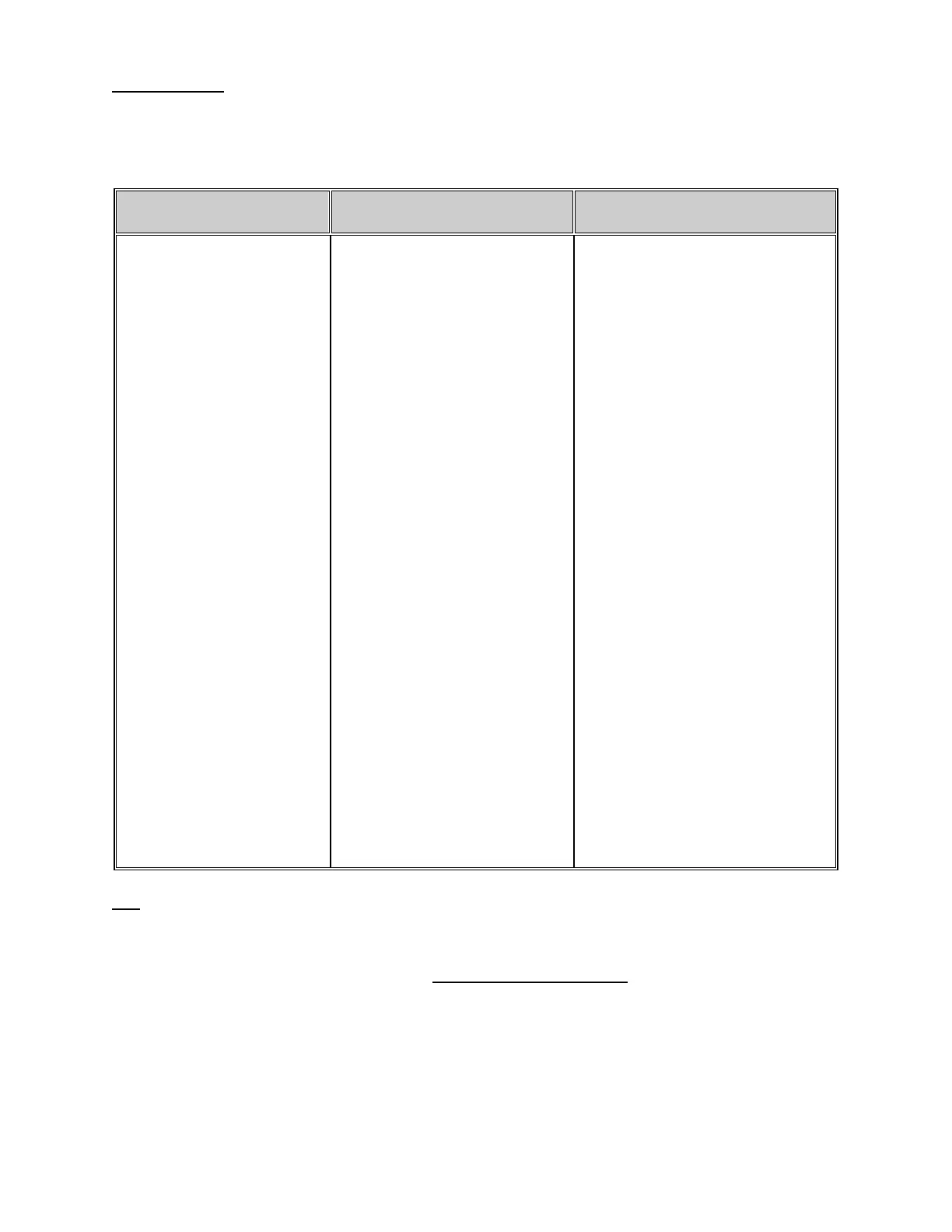

TROUBLE POSSIBLE CAUSE CORRECTIVE REPAIR INSTRUCTIONS

(Refer to pump Repair Section)

Pump will not hold pressure

Pump fails to supply pressure

Pump piston does not draw a full

charge. (This is evident by a cushion

effect at the top of the pump stroke.)

Pump piston raises by itself under

pressure

Pump functions properly but will

generate only a given pressure below its

normal pressure maximum

Pump fails to supply greater output at no

load than under load

1 -

2 -

3 -

4 -

1 -

2 -

3 -

4 -

5 -

6 -

Release valve ball not seating properly

Ball Valves not seating properly

Overload valve ball not seating

properly

Large pump relief valve seal faulty

Lack of oil

Air bound pump

Release valve ball not seating properly

Small ball in ball valve circuit not

seating properly

Overload valve ball not seating

properly

Large pump relief valve seal faulty

Air bound system

Lack of oil

Large ball in ball valve circuit not

seating properly

Overload valve not set properly

Large pump relief valve not set

properly

Refer - "Release Valve"

Refer - Pump Valve

Refer - Overload Valve

Refer - Large Pump Relief Valve

Refer - Oil

Air Bleeding Section

Refer - Release Valve

Refer - Pump Valve

Refer - Overload Valve

Refer - Relief Valve

Air Bleeding Section

Refer - Oil

Refer - Pump Valve

Refer - Overload Valve

Refer - Relief Valve

OIL

If the pump fails to operate, check the oil level before attempting any repairs.

CAUTION: Use only Hydraulic Oil when refilling. NEVER USE BRAKE FLUID

Loading...

Loading...