11-8

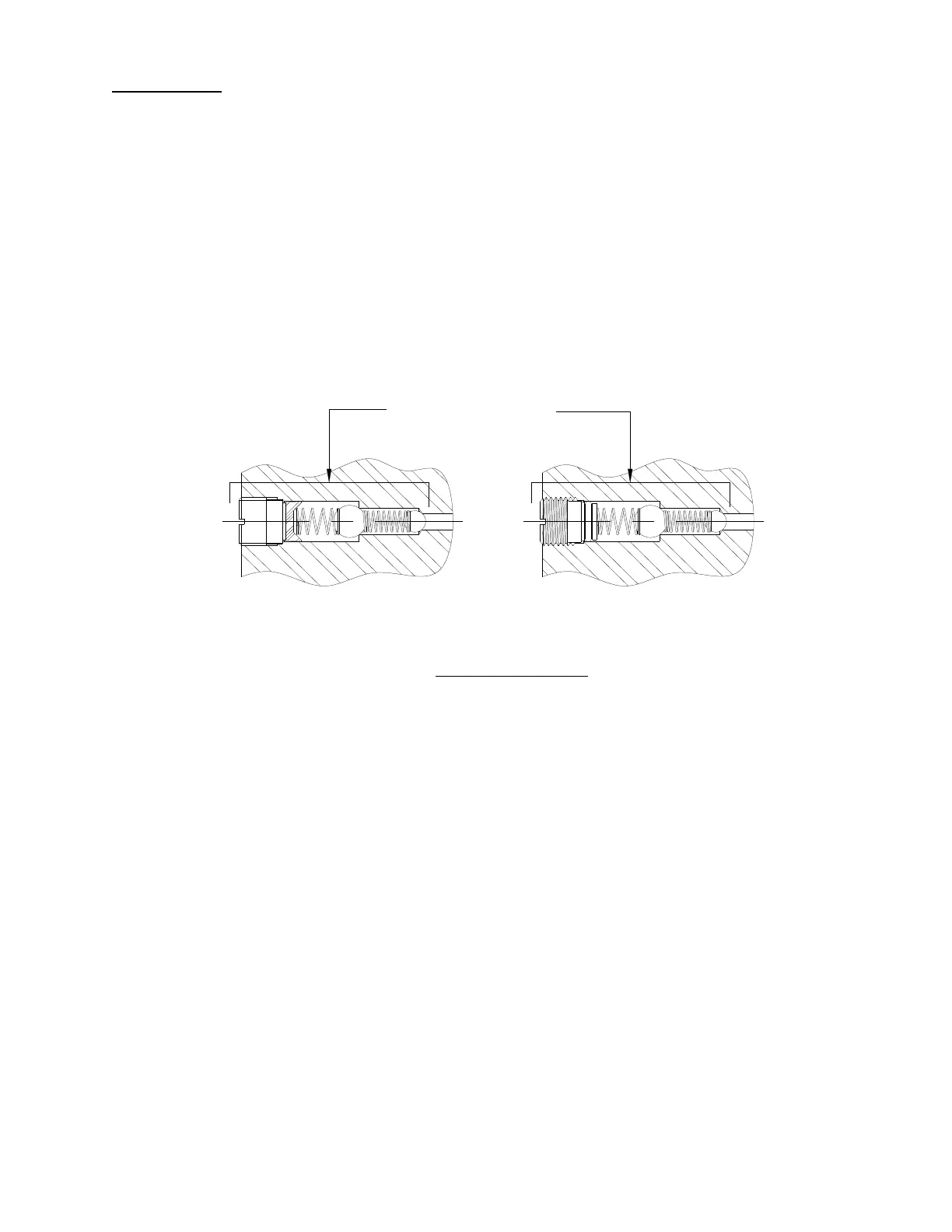

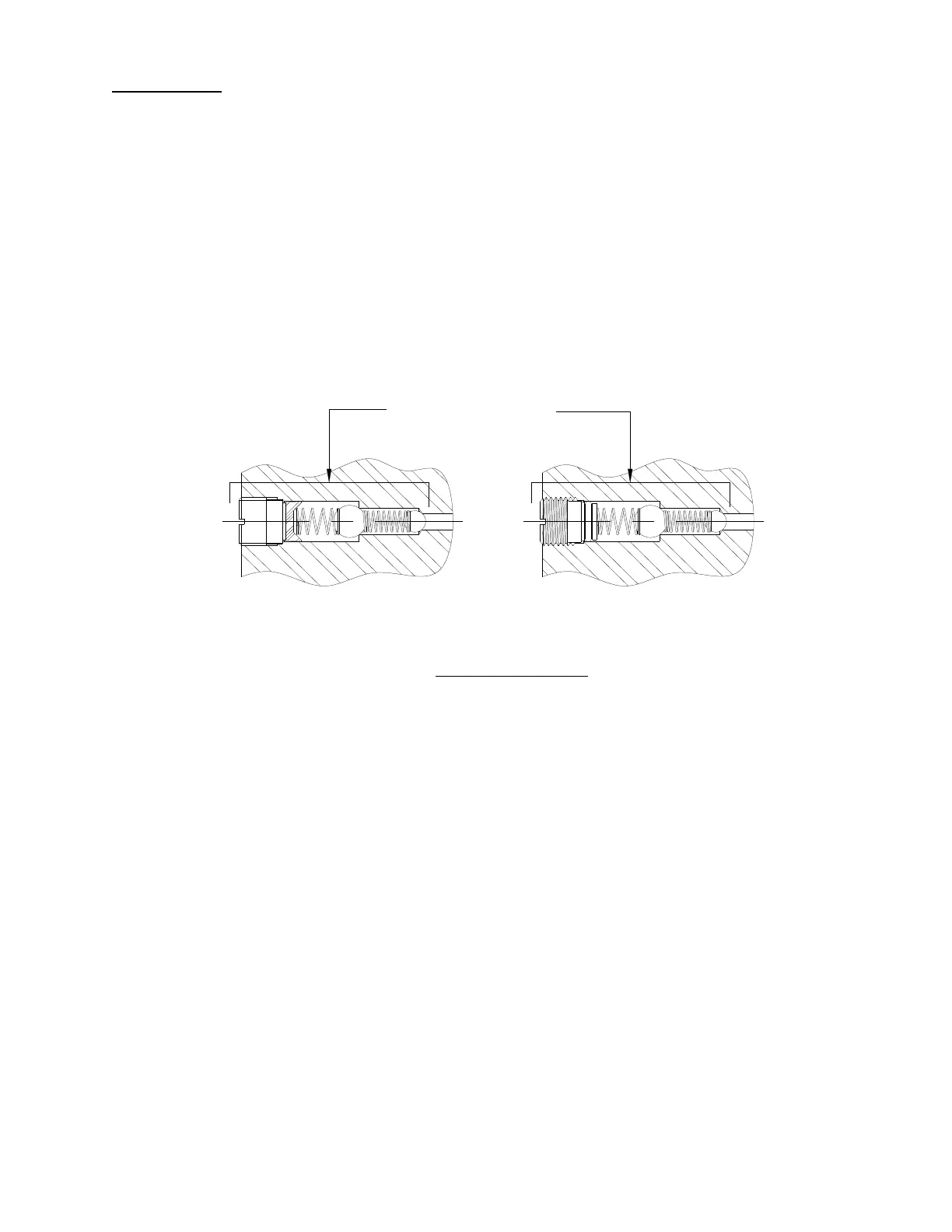

PUMP VALVES

If the pump fails to supply pressure or if the pump piston is under pressure at all times, the pump valves may need a

cleaning. Stand pump in upright position while removing valve plug and valve seal. Tilt pump to remove valve springs

and balls. Allow oil to drain from the reservoir through these valve holes to wash foreign matter from hole. Lay pump

on its side to clean and inspect valve chamber. Be careful not to mar or nick ball valve seats. Clean valve balls and

spring in a solvent. Replace rusted or corroded balls. Do not stretch ball springs. To reassemble, insert, in sequence,

small ball, small spring, large ball and large spring in cleaned chamber. Using the valve seal inserting tool (CP13-44),

assemble new valve seal. Finally, screw in valve seal plug.

This procedure should be carried out in all ball valve circuits. If the valves fail to operate properly after they have been

cleaned, it may be necessary to reseat the valve balls. Remove the springs and tap each ball lightly in its respective seat

using the 1/4" ball seating tool (CP13-42) for the small ball and 7/16" ball seating tool (CP13-43) for the large ball.

Remove balls to make sure they are not stuck to the seats. Reassemble pump valves as before.

OLD STYLE

VALVE PLUG VALVE PLUG

NEW STYLE

SECTION D-D

PUMP VALVE

REPAIR PARTS KIT

329045

Loading...

Loading...