INTRODUCTION

Basic instructions - Chain Wear Tables - Roller Chains

AXIAL-FLOW 5130, AXIAL-FLOW 6130, AXIAL-FLOW 7130

Chain wear

The individual joints in a roller chain articulat e as they en-

ter and leave the sprockets. This articulation results in

wear on the pins and bushings. Material that is worn away

from these surfaces will cause the chain to gradually elon-

gat e. Chains do not stretch. Material is worn from pin and

bushing.

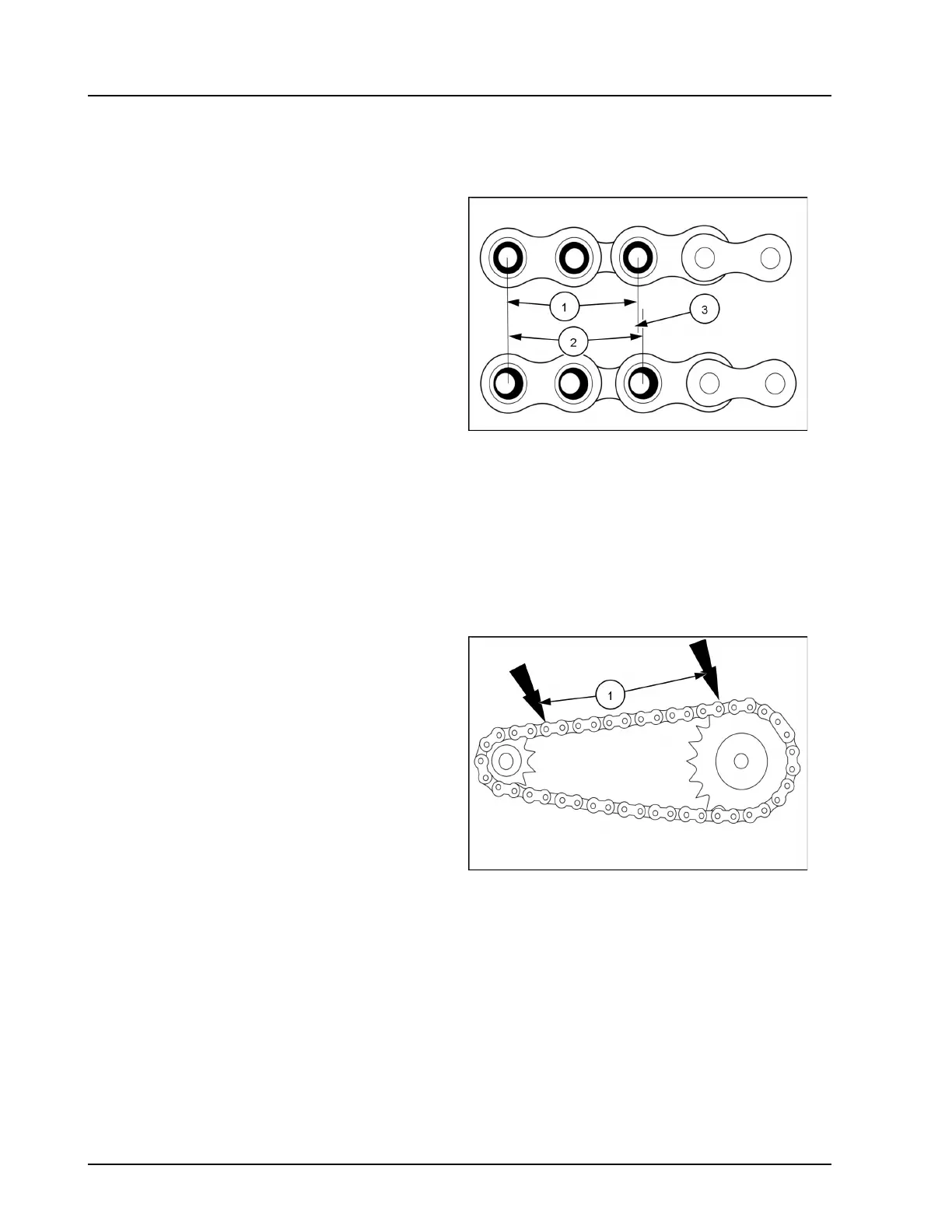

Critical dimensions of the chain are as follows:

•

(1) 2X pitch

•

(2) Wear plus 2X pitch

•

(3) Elongation due to pin and bushing wear

96091478

1

Elongat ion is normal and may be minimized by proper

lubrication and drive maintenance. The rate of wear is

dependent upon: the relationship between the load and

the amount of bearing area between pin and bushing, the

material and surface condition of the bearing surfaces, the

adequacy of lubrication, and the frequency and degree

of articulation between pins and bushings. The latter is

det ermined by the quantity of sprockets in the drive, their

speeds, the number of teeth and the length of the chain

in pitches.

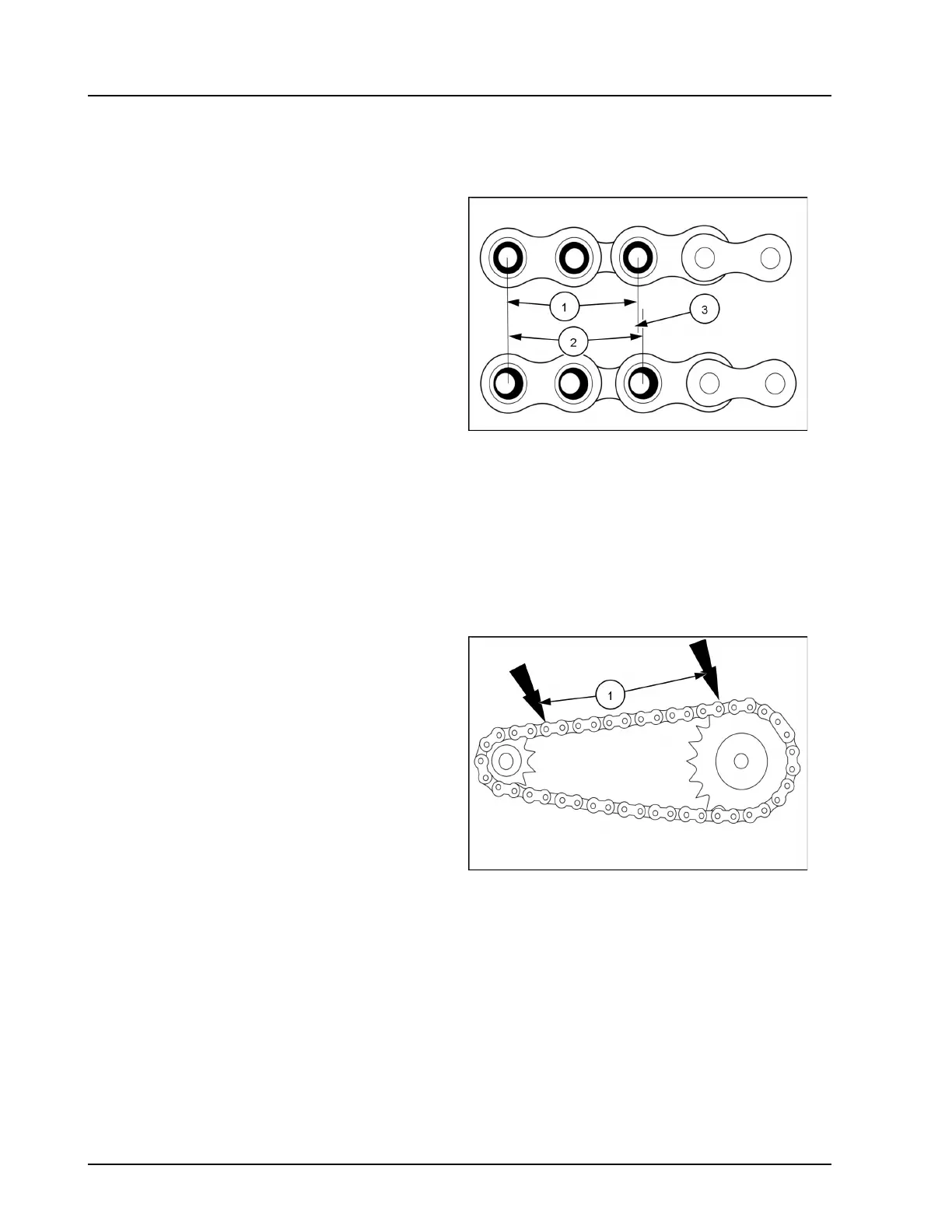

An accurate wear measurement (1) can be made by us-

ing the above illust ration. Measure as closely as possible

from the center of one pin to the center of another. The

more pitches (pins) cont ained within the measurement in-

crease the accuracy. If the measured value exceeds the

nominal by more than the allowable percentage the chain

should be replaced. The maximum allowable wear elon-

gat ion is approximately 3 % for most industrial applica-

tions, based upon sprocket design. The allowable chain

wear in percent can be calculated using the relationship:

200 / (N), where (N) is the number of teeth in the large

sprocket. This relationship is often useful since the nor-

mal maximum allowable chain wear elongation of 3 % is

valid only up to 67 teeth in the large sprocket. In drives

having xed center distances, chains running in parallel

or where smoother operation is required, wear should be

limited to approximately 1.5 %.

For example, if 12 pitches (12 pins) of a #80 chain were

measured and the result was 313.944 mm (12.360 in) or

greater (using 3 % as the maximum allowable wear), the

chain should be replaced. Anything less than 313.944

mm (12.360 in) would still be acceptable by most indus-

trial standards.

96091469

2

47506838 04/04/2013

18

Loading...

Loading...