SECTION 58 - DRIVELINES - CHAPTER 3

58-3

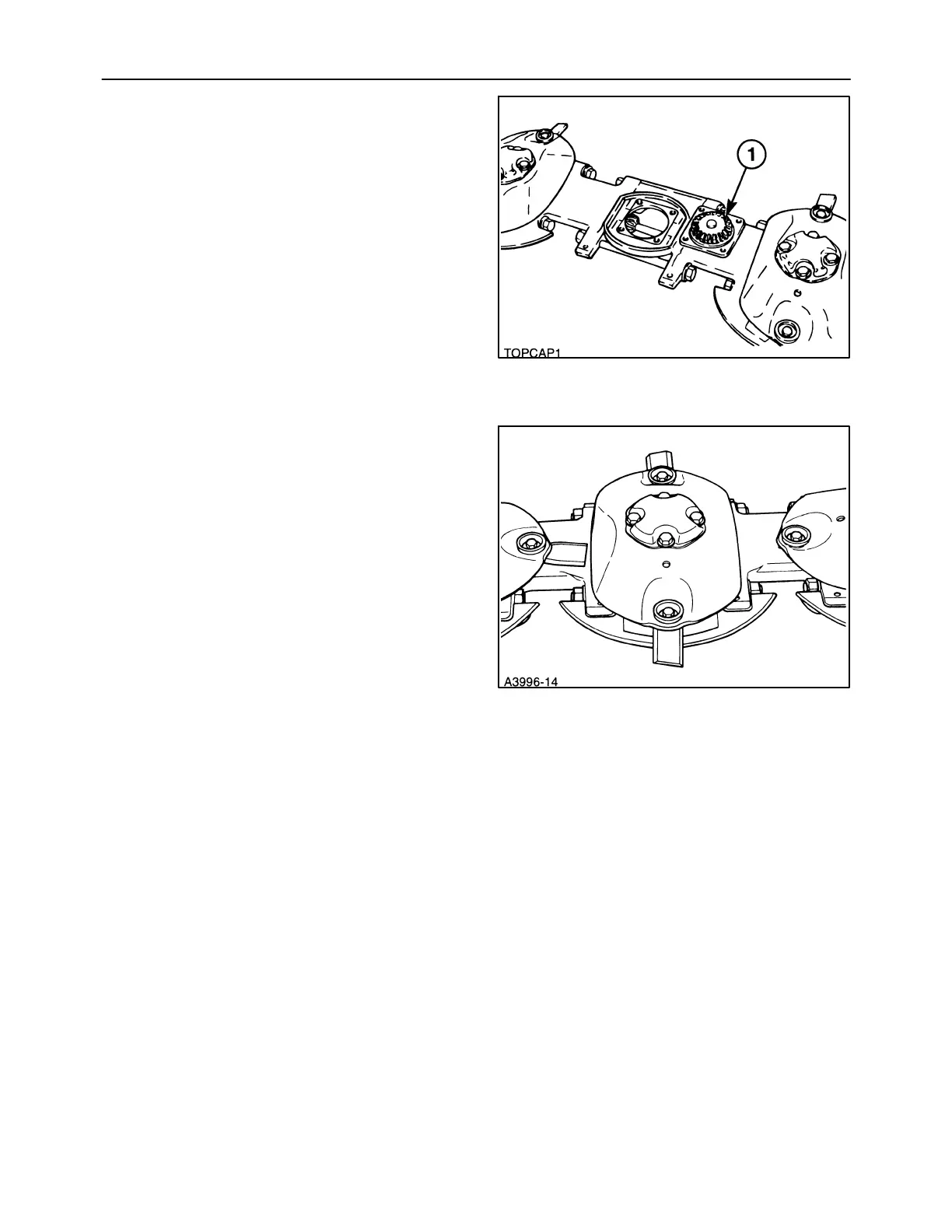

If a problem is found with a specific module, the

extent of the damage can be quickly determined by

removing the disc and the top cap assembly, 1, of the

affected module. If damage is limited to the top cap

assembly components, the lower module can be

flushed out to remove contaminants, and a new top

cap assembly installed to complete the repair.

The cutterbar uses small diameter, high profile discs,

which are 3/16 inch and hardened for long wear. The

profile of the discs provides a natural lifting action,

which helps fluff the cut crop for faster drying.

The discs are equipped with 2 inch wide knives,

which are retained with 1/2 inch bolts and hardened

knife nuts. The knives are reversible for long life, and

always have the beveled edge up. An arrow is

stamped on both sides of the knife to show the

direction of rotation.

Heat treated knife bolt protectors serve as a wear

surface to guard the bolt from deterioration, and can

be rotated to extend life. The knives can be easily

changed in any position on the cutterbar.

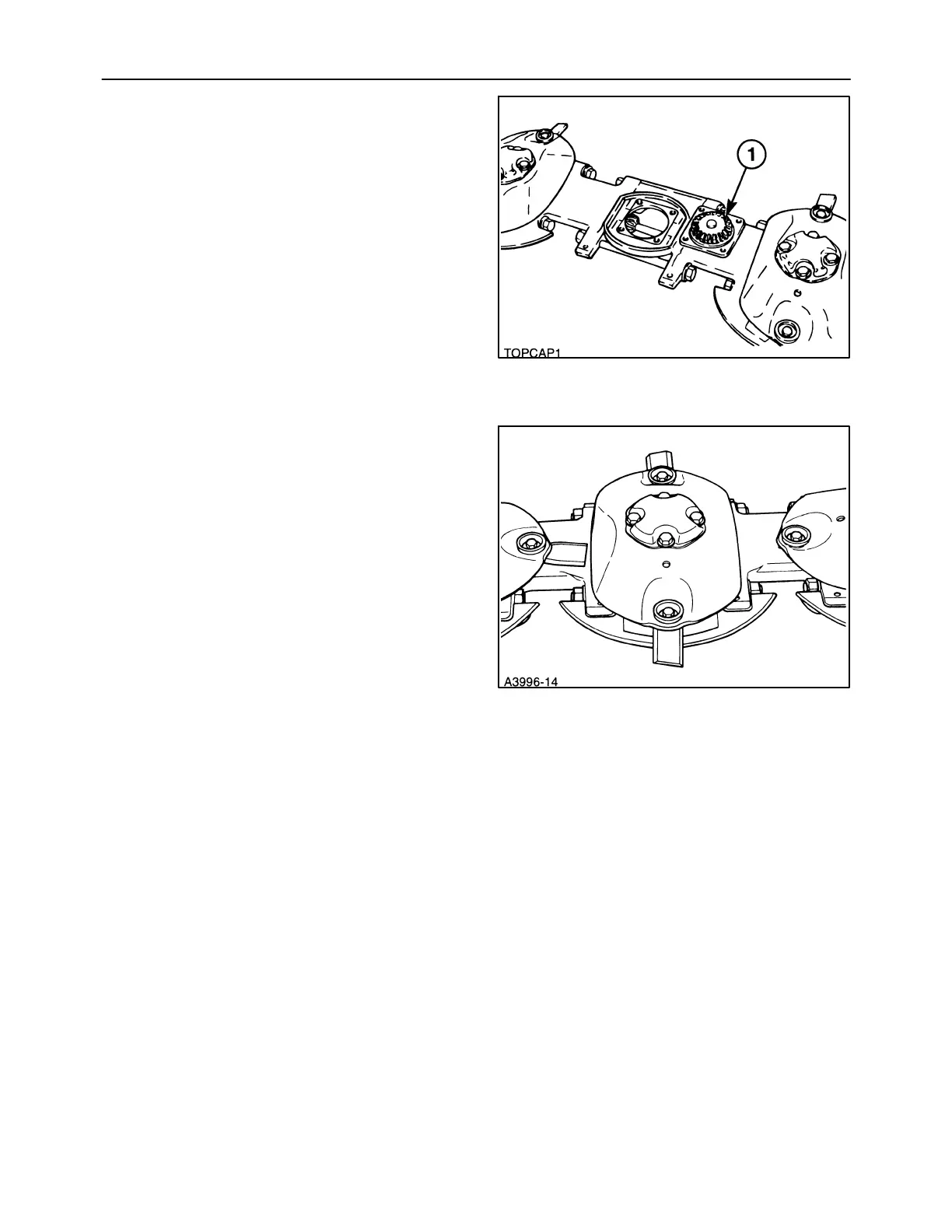

Each disc module is protected by a hardened ductile

iron rock guard and a skid shoe.

Skid shoes are 1/4 inch thick and 8 inch wide; they

extend behind the module several inches for

optimum flotation and extended wear life of the shoe.

3

4

Loading...

Loading...