INTRODUCTION

1.Priortoaddingdye,connecttheblacklighttothe

machinesbatteryandinvestigatesuspectedareas.

2.Oncesuspectedleakareasarefound,attemptto

tracetheleakcompletelytotheorigin.

NOTE:Attheorigin,theleakshouldbethebrightest

incolor.

3.Afterconrmationofthesuspectedleak,thoroughly

cleantheareaoftheleaktoremoveanyexistingu-

ids.Rechecktheareawiththeblacklighttoassure

theareaisclean.Goodcleaningisimportantforthe

followingreasons:

•

Fluidscapturedbythreadedjointsorother

cavitieswillcontinuetoshowsignsofleakage

unlesscompletelyclean.

•

Castingsurfacescanholdresidualoil.

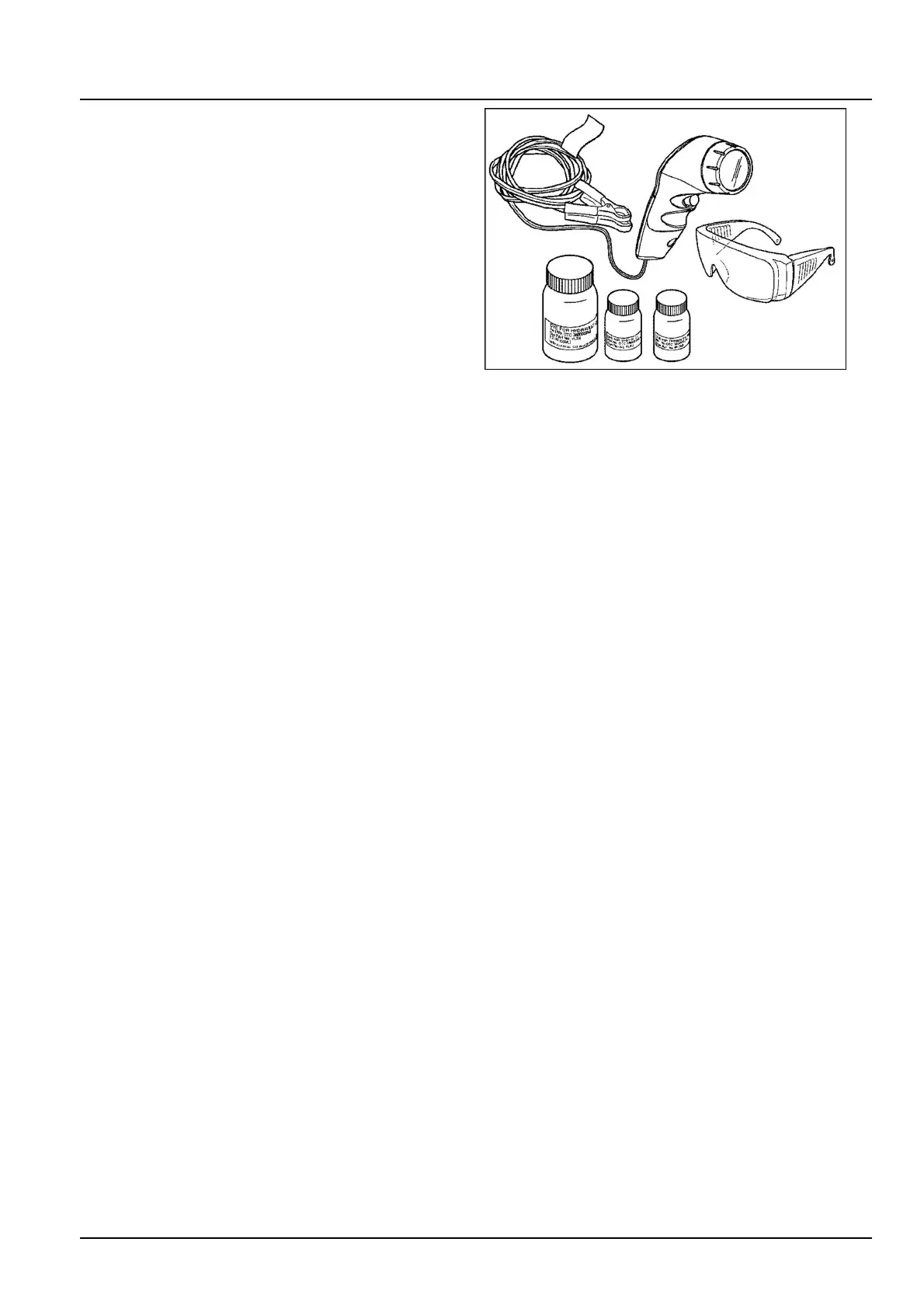

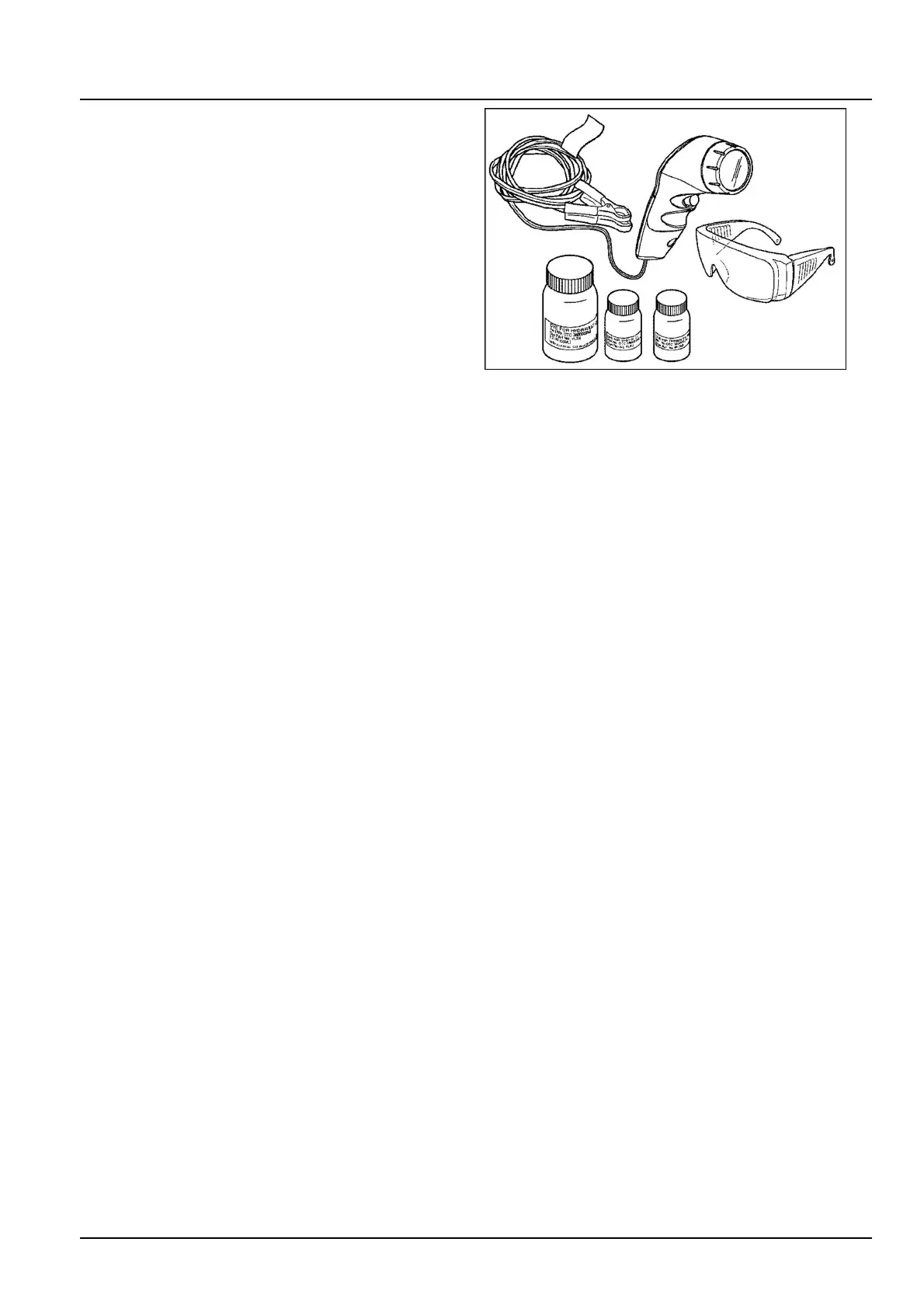

RCPH10TLB245ACL1

4.Usetheentirecontentsofthebottleofdyeinthe

system/systemsofthesuspectedleak.

5.Runtheunitfor5to10minutesandcyclethrough

suspectsystemfunctionstoensurethatthedyeis

availabletoallpossibleleakpoints.

NOTE:Thehydraulicoilshouldbeheatedto71°C

(160°F),engineatnormaloperatingtemperature,

andtransmissionshouldbeinthenormaloperating

rangeonthegauge.

6.Useacleanclothandwipethedipstickortheinside

surfaceofthellertubeoneachofthe3sumps.

7.Viewtracesofdyeduidontheclothundertheblack

lighttoensuregoodsamples.

8.Usethese3samplesasyourbaselinewheninspect-

ingtheunitwiththeblacklight.

NOTE:Highhourengineoilcanreducetheeffec-

tivenessofthedye.Inthiseventchangetheoil.

9.Avoidcommonerrors.

•

Fanairowblowingleakinguid.

•

Gravitypullingleakpathsdown.

•

Whenpaintatajointisnotbroken,thejointis

notleaking.

NOTE:Itisnotnecessarytochangeoilsafterthis

check.

4744159427/09/2012

35

Loading...

Loading...