4 - 6

DIAGNOSTIC - SELECTION

CASE TRAINING CENTER

AUGUST 2000

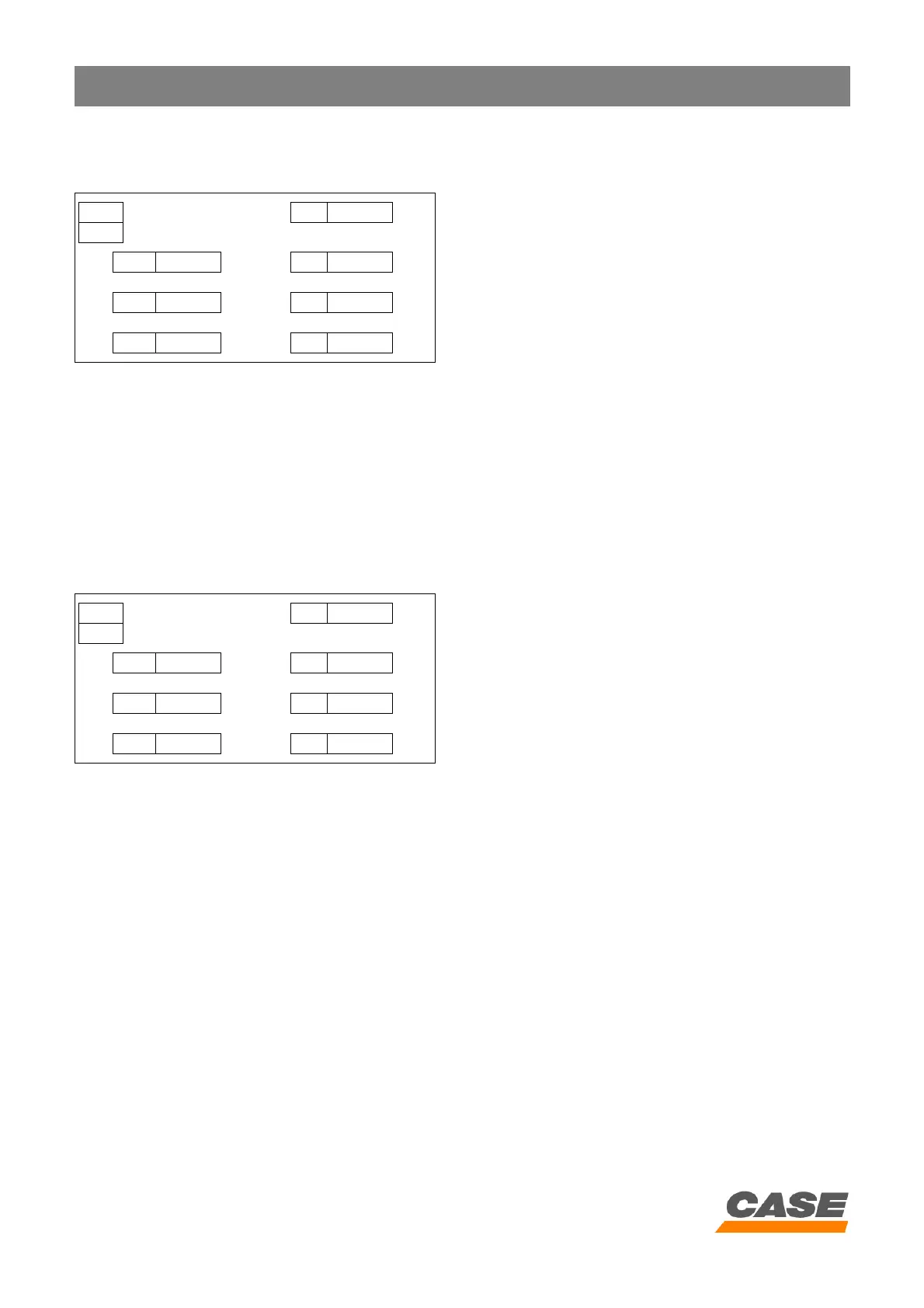

3. Previous failures in the engine DIAG3

This screen is connected to the previous screen (DIAG2) as concerns failures involving the hourmeter.

Example:

The screen above shows that the failure code 0032 (electronic regulator rack position detector) occurred at 1200

H and that failure code 0016 (fuel temperature sender) occurred at 1000 H.

A. the number of hours shown indicates the time at which the failures occurred for the first time since the data was re-

initialised.

B. If you wish to erase the failure codes and the number of hours, press the work mode switch for 10 seconds.

C. When data is erased from screens DIAG2 and DIAG3. it is recorded in the electronic control box memory (this data

is only visible using an external computer).

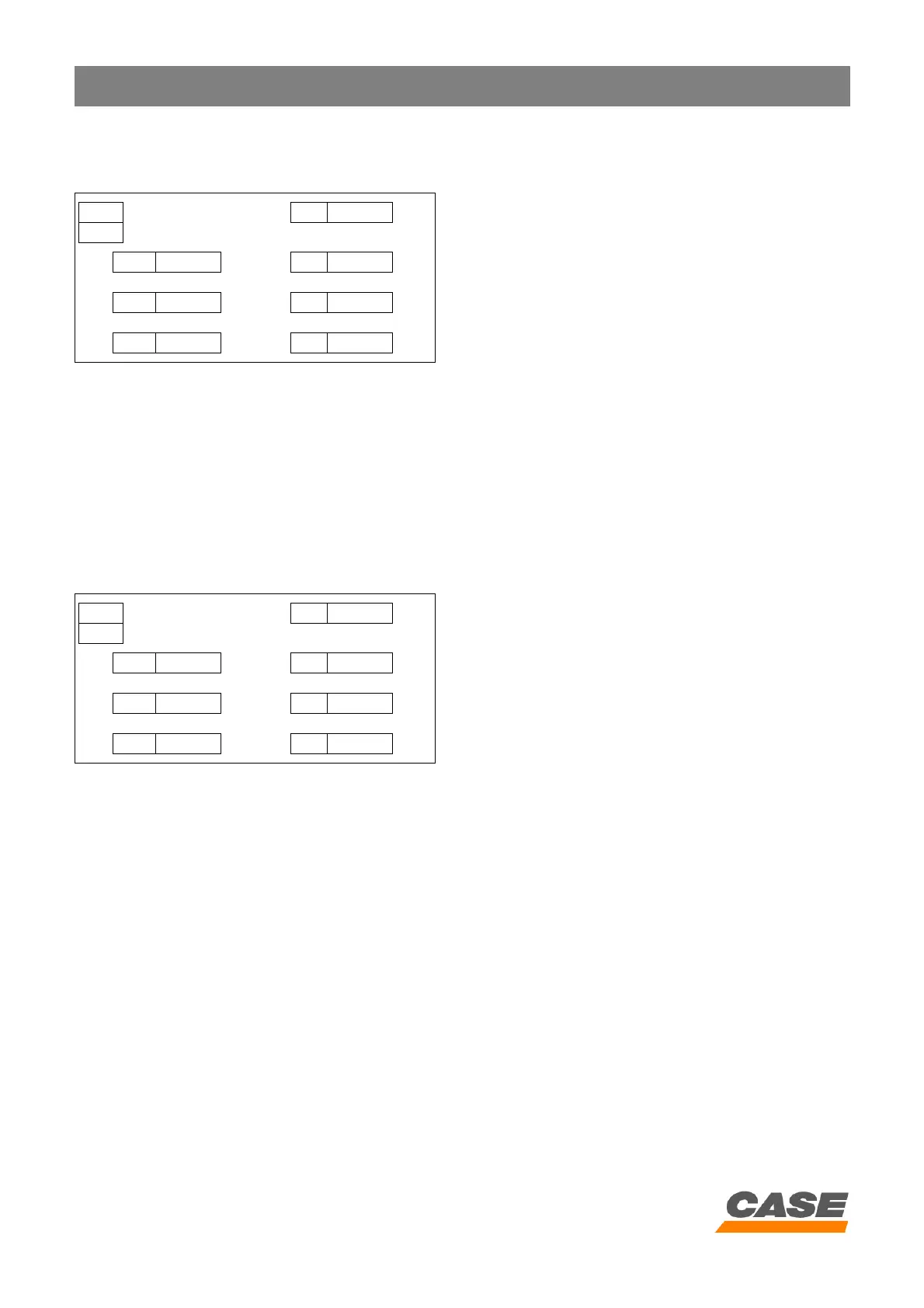

4. Excavator failure detection DIAG4

Failure code

Example:

The screen above shows a failure in the hydraulic oil temperature sender (0020).

DIAG MODE II H E 0000

3

E 1200 E 0000

E 1000 E 0000

E 0000 E 0000

E: Failure code

DIAG MODE II H M 0000

4

M 0020 M 0000

M 0000 M 0000

M 0000 M 0000

M: Failure code

M0000: No defect

M0010: Transistor output short-circuit

M0020: Hydraulic oil temperature sender

M0030: Fuel level sender

M0040: Pressure detector P1

M0050: Pressure detector P2

M0060: Pump regulating pressure detector

M0070: Starter motor switch

M0080: Attachment or travel pilot pressure switch

M0090: CAN communication circuit

M00A0: Electronic control box re-initialisation

M00B0: Engine electronic control box

M00C0: Boom cylinder pressure

Loading...

Loading...