PROCEDURE

3) IN CASE OF HAMMER AND WEDGE JAMMING

10

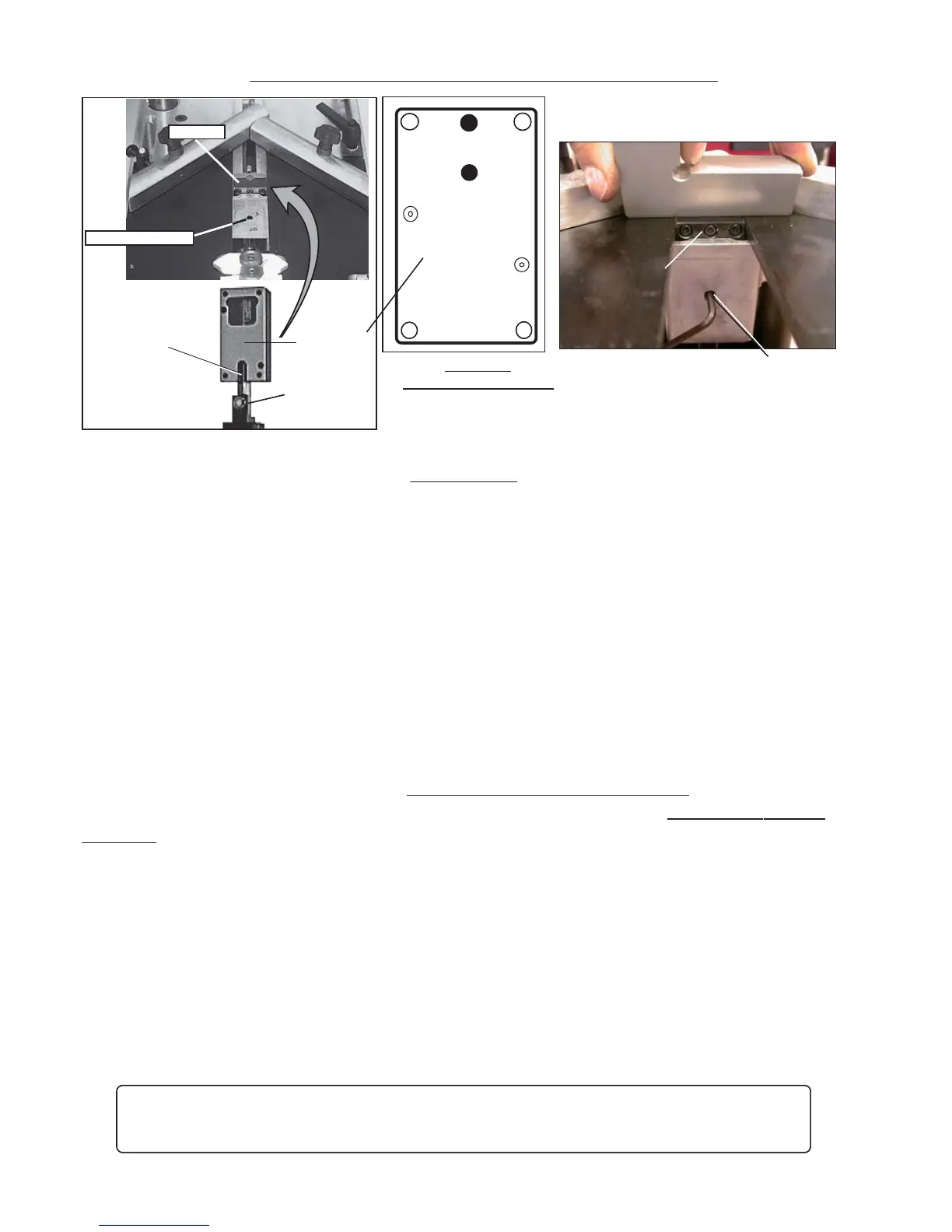

HAMMER

BLOCK H

BLOCK H

locking screw

HAMMER

RETAINING

SCREW

Z1394

A

BC

D

GF1

GF2

D

E

BLOC H

SCREW POSITIONS

If you have any difficulty to remove the block H from the machine, push down

with your hands the top presser’s bracket arm.This should free the block H that

is stuck with the hammer.

- Remove the cartridge that is on machine, and the top presser.

- Using the 3mm Allen key, loosen the locking screw of the wedge distributor Block H.

- Then lift the top presser’s bracket arm by hand. The wedge distributor will come out of its

housing. Remove it from the machine.

- The old hammer (wedge driver blade) is stuck in the wedge distributor : first try to remove it

with a pair of pliers. If not possible, unscrew the two central screws (GF1, GF2) that hold the

fixed (square) guide of Block H in place. Use for this the smaller (2.5mm) Allen key supplied

with the machine. Remove the fixed guide completely to free the old hammer. If still not possi-

ble to get rid of the old hammer, remove the four screws (A, B, C, D) and open the block H.

- Remove the old hammer. Assemble the Block H back again.

Putting a new hammer (driver blade) :

- Put a drop of grease in the bottom hole of the wedge distributor (block H).

- Insert a new hammer into block H with

the hole of the hammer downwards.

- Re-position the wedge distributor in its housing on the machine with the

window towards the

cartridge.

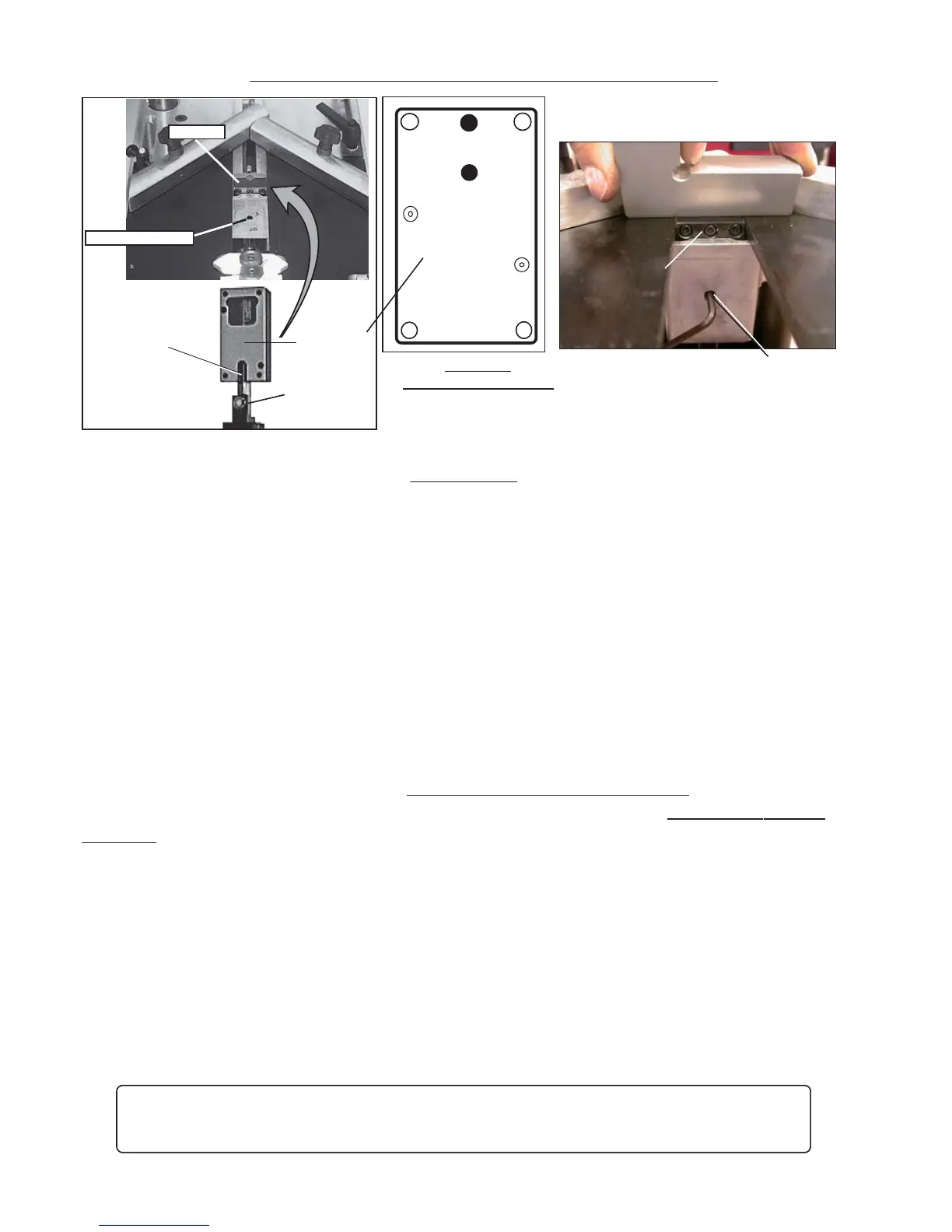

- If the upper end of the hammer stays out of the block H, push it fully in with a piece of wood

or moulding.

While keeping the moulding in place (on block H) and pressing on it, pull up the top presser’s

bracket arm Po (Fig1 p1) with a quick movement.

The new hammer must have taken its position in the mechanism automatically.

- Check with your finger or with a ruler that the block H does not stay out of the machine

(higher than the work level) and tighten the locking screw of block H. No need to tighten too

much.

- The machine is ready to work again.

fig 0

RULER

WEDGE

DISTRIBUTOR

(BLOCK H)

SLIDING

TABLE

LOCKING SCREW

Loading...

Loading...