9

9

Table 3

WELDING THICKNESS (mm) Ø ELECTRODE (mm)

1,5 ÷ 3

3 ÷ 5

5 ÷ 12

≥ 12

2

2,5

3,2

4

Table 4

Ø ELECTRODE (mm) CURRENT (A)

1,6

2

2,5

3,2

4

30 ÷ 60

40 ÷ 75

60 ÷ 110

95 ÷ 140

140 ÷ 190

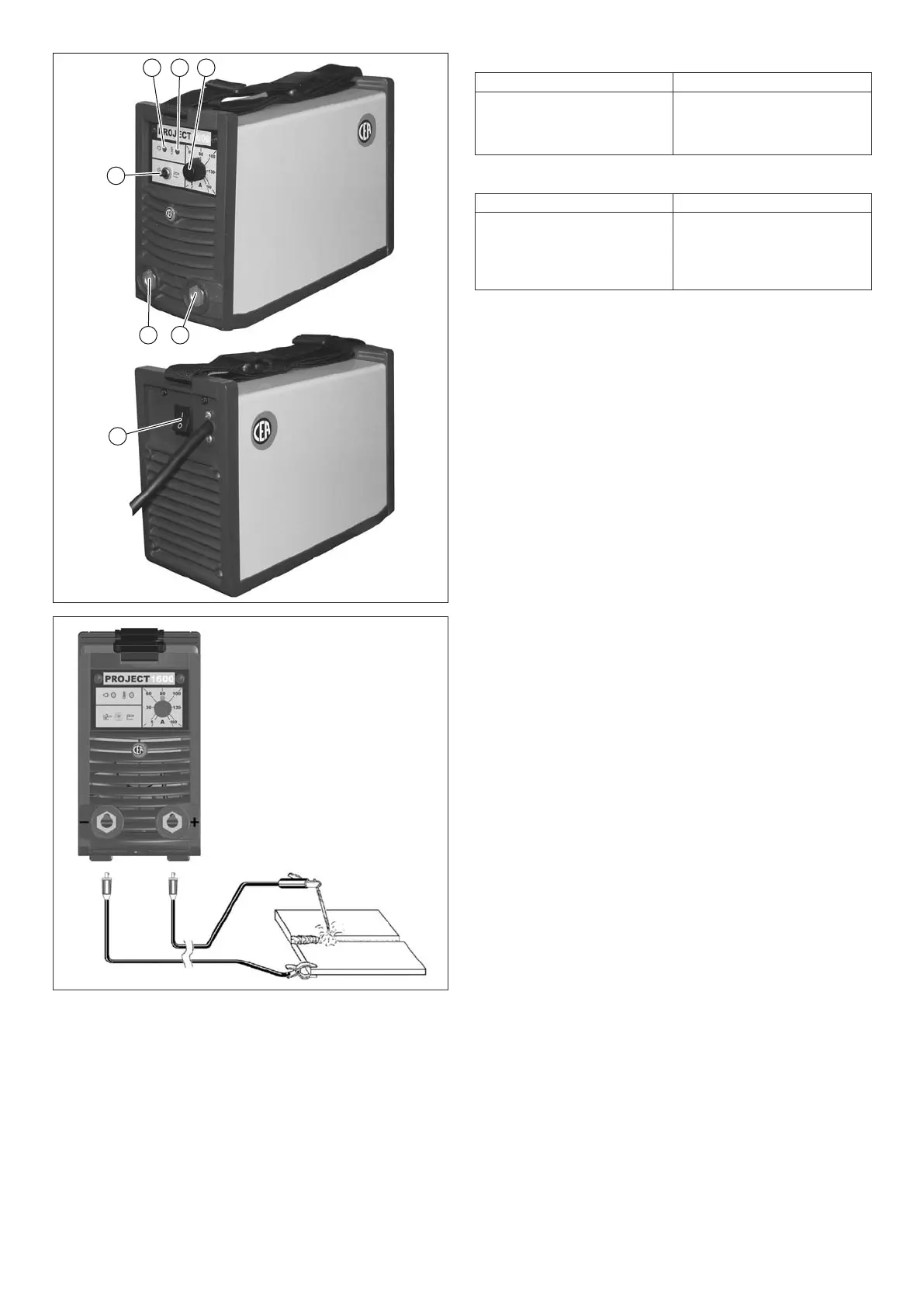

FIG. B

1 2 3

45

7

6

FIG. A

2000HA28

4) Start the welding machine by selecting position 1 on the

line switch (Pos. 7, Fig. A).

5) The white LED (Pos. 1, Fig. A) indicates that the welding

machine is powered and ready to work.

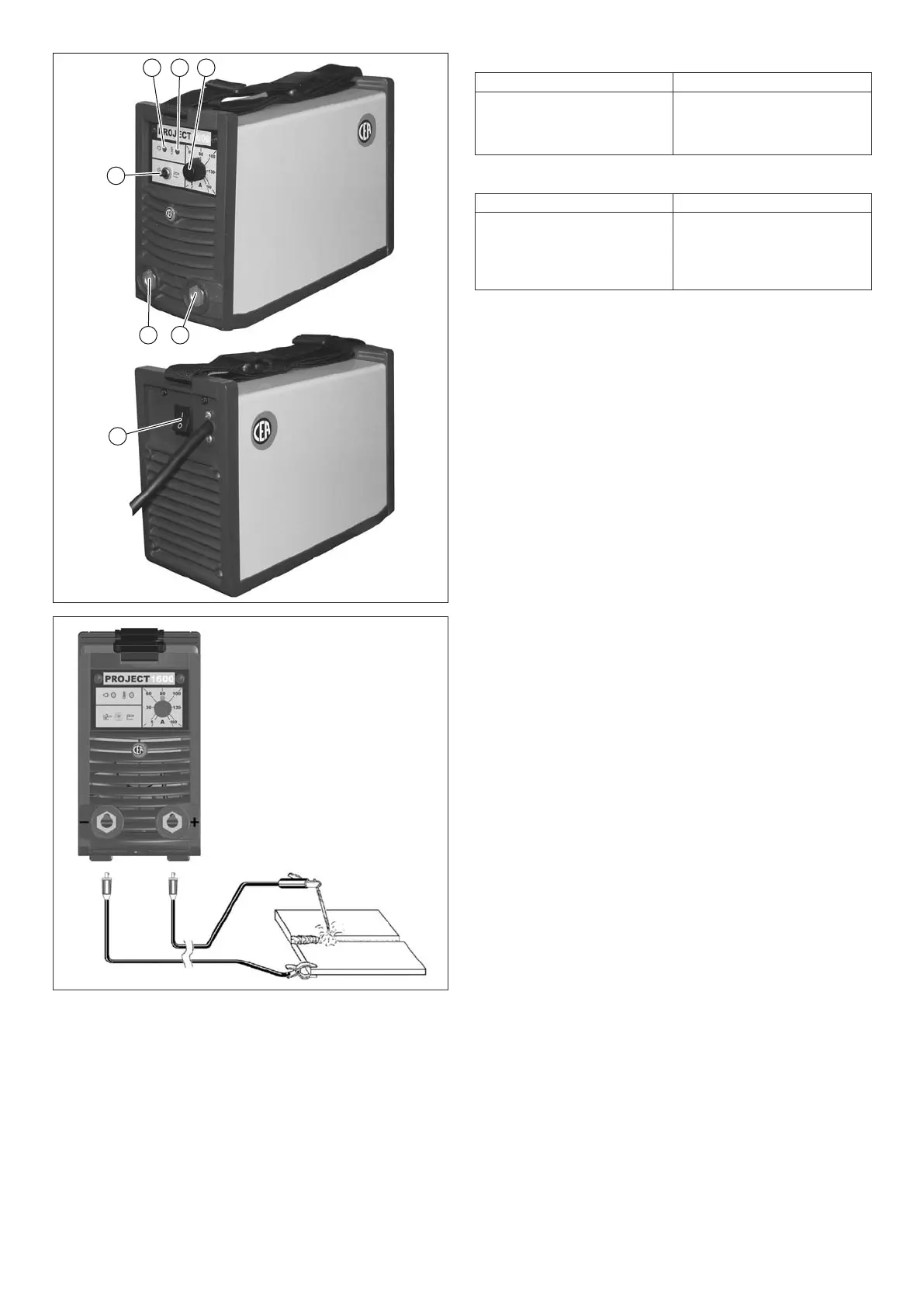

6) Carry out welding by moving the torch to the workpiece.

Strike the arc (press the electrode quickly against the met-

al and then lift it) to melt the electrode, the coating of which

forms a protective residue. Then continue welding by mov-

ing the electrode from left to right, inclining it by about 60°

compared with the metal in relation to the direction of weld-

ing.

PART TO BE WELDED

The part to be welded must always be connected to earth in or-

der to reduce electromagnetic emission. Much attention must

be afforded so that the earth connection of the part to be weld-

ed does not increase the risk of accident to the user or the risk

of damage to other electric equipment.

When it is necessary to connect the part to be welded to earth,

you should make a direct connection between the part and the

earth shaft. In those countries in which such a connection is

not allowed, connect the part to be welded to earth using sui-

table capacitors, in compliance with the national regulations.

WELDING PARAMETERS

Table 3 shows some general indications for the choice of elec-

trode, based on the thickness of the parts to be welded.

The values of current to use are shown in the table with the

respective electrodes for the welding of common steels and

low-grade alloys. These data have no absolute value and are

indicative data only. For a precise choice follow the instruc tions

provided by the electrode manufacturer.

The current to be used depends on the welding positions and

the type of joint, and it increases according to the thickness and

dimensions of the part.

The current intensity to be used for the different types of wel-

ding, within the field of regulation shown in table 4 is:

• High for plane, frontal plane and vertical upwards welding.

• Medium for overhead welding.

•

Low for vertical downwards welding and for joining small pre-

heated pieces.

A fairly approximate indication of the average current to use in

the welding of electrodes for ordinary steel is given by the fol-

lowing formula:

I = 50 x (Øe - 1)

Where:

I = intensity of the welding current

Øe = electrode diameter

Example:

For electrode diameter 4 mm

I = 50 x (4 -1) = 50 x 3 = 150A

Loading...

Loading...