10

10

2000HA39

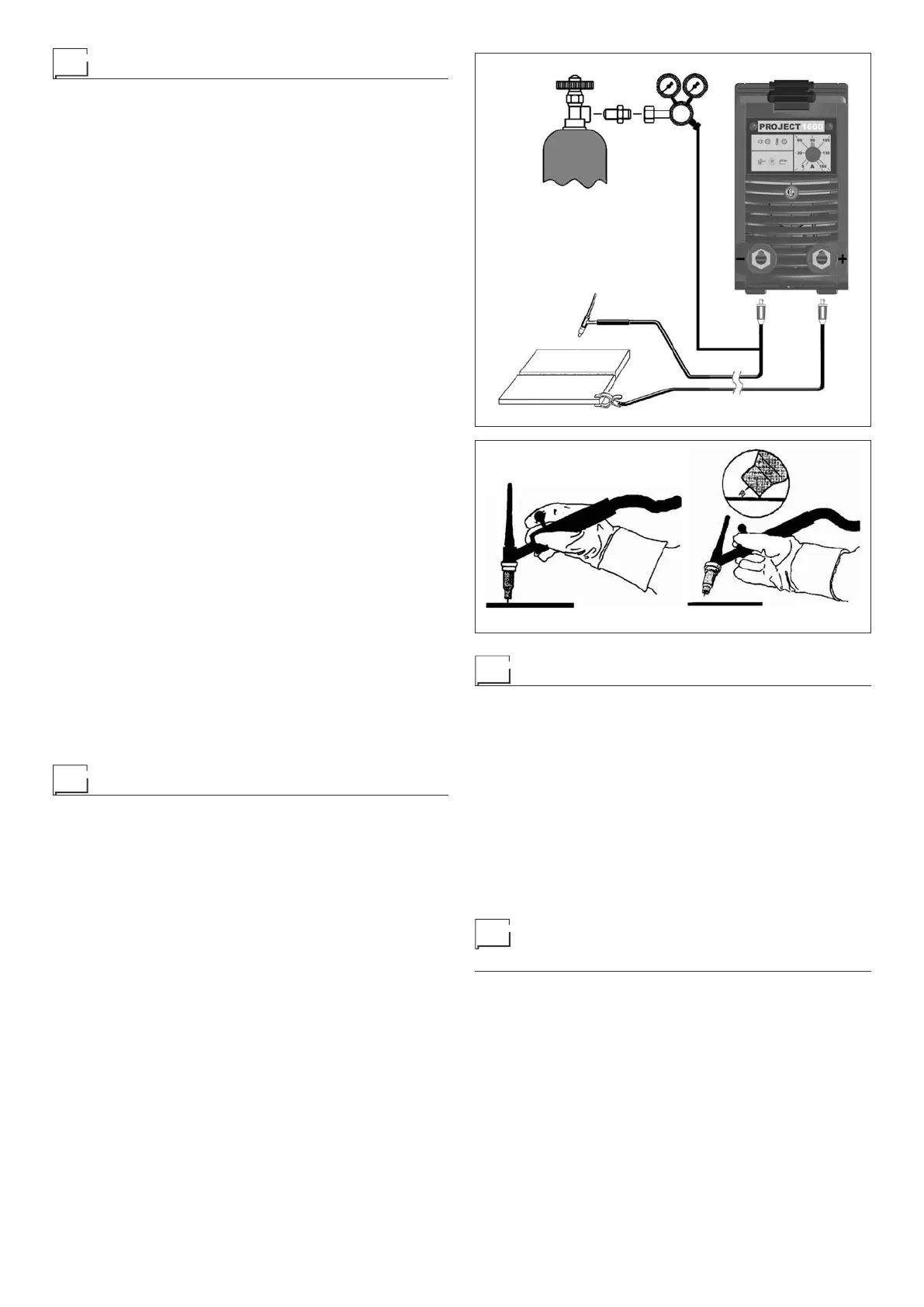

FIG. D

FIG. C

2000HA29

TIG welding (Fig. C)

TIG welding melts the metal of the workpiece, using an arc

struck by a tungsten electrode.

The fusion bath and the electrode are protected by gas (Argon).

This type of welding is used to weld thin sheet metal or when

elevated quality is required.

1) Connecting the welding cables:

•

Connect one end of the gas hose to the gas connecter

on the TIG torch and the other end to the Argon cylin-

der and open it.

• With the machine switched off:

-

Connect the earth cable to the snap-on connector

marked + (positive).

-

Connect the relative earth clamp to the workpiece or

to the workpiece support in an area free of rust, paint,

grease, etc..

-

Connect the TIG torch power cable to the snap-on con-

nector marked - (negative).

2) Adjust the welding current using the potentiometer (Pos. 3,

Fig. A).

3) Adjust the process switch (Pos. 6, Fig. A) to TIG (switch le-

ver moved to the left-hand side).

4) Start the welding machine by selecting pos. 1 on the line

switch (Pos. 7, Fig. A).

5) The white LED (Pos. 1, Fig. A) indicates that the welding

machine is powered and ready to work.

6) Adjust the gas flow by manually turning the valve on the

TIG torch.

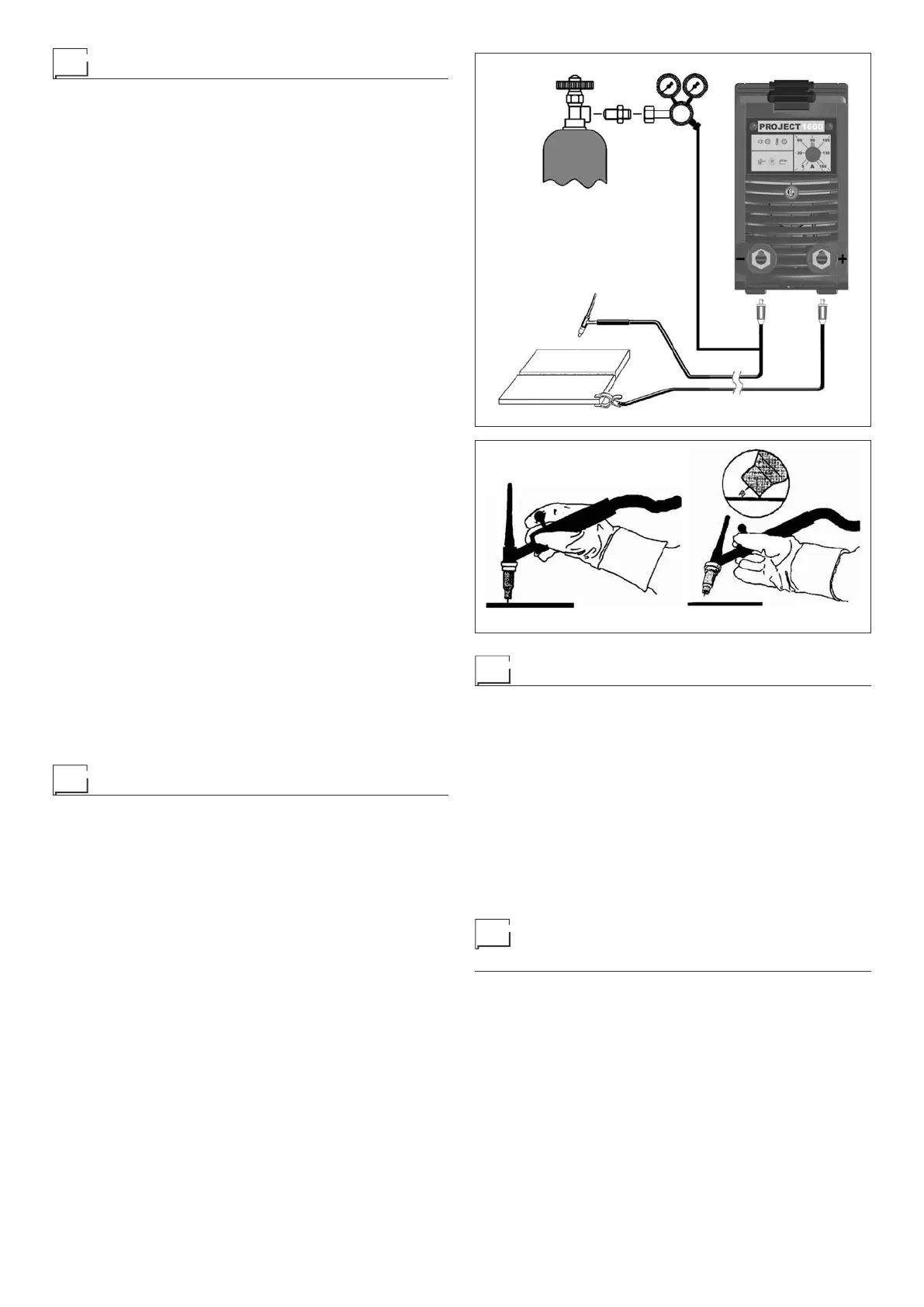

7) The “Lift” function strikes the arc when the TIG torch elec-

trode comes into contact with the workpiece and is then

removed (see Fig. D).

8) Carry out TIG welding.

PART TO BE WELDED

The part to be welded must always be connected to earth in or-

der to reduce electromagnetic emission. Much attention must

be afforded so that the earth connection of the part to be weld-

ed does not increase the risk of accident to the user or the risk

of damage to other electric equipment.

When it is necessary to connect the part to be welded to earth,

you should make a direct connection between the part and the

earth shaft. In those countries in which such a connection is

not allowed, connect the part to be welded to earth using sui-

table capacitors, in compliance with the national regulations.

Maintenance

ATTENTION: before carrying out any inspection of the inside

of the generator, disconnect the system from the supply.

SPARE PARTS

Original spare parts have been specially designed for our equi-

pment. The use of non-original spare parts may cause varia-

tions in performance or reduce the foreseen level of safety.

We decline all responsibility for the use of non-original spare

parts.

GENERATOR

As these systems are completely static, proceed as follow:

•

Periodic removal of accumulated dirt and dust from the inside

of the generator, using compressed air. Do not aim the air

jet directly onto the electrical components, in order to avoid

damaging them.

• Make periodical inspections in order to individuate worn ca-

bles or loose connections that are the cause of overhea ting.

Possible problems and remedies

The supply line is attributed with the cause of the most com-

mon difficulties. In the case of breakdown, proceed as follows:

1) Check the value of the supply voltage.

2) Check that the power cable is perfectly connected to the

plug and the supply switch.

3) Check that the power fuses are not burned out or loose.

4) Check whether the following are defective:

• The switch that supplies the machine.

• The plug socket in the wall.

• The generator switch.

NOTE: given the required technical skills necessary for the re-

pair of the generator, in case of breakdown we advise you to

contact skilled personnel or our technical service department.

Procedure for welder assembly

and disassembly

Proceed as follows:

•

Undo the 4 screws securing the cover to the front and rear

panel.

• Remove the cover from its seat.

Proceed the other way round to re-assemble the welder.

Loading...

Loading...