9

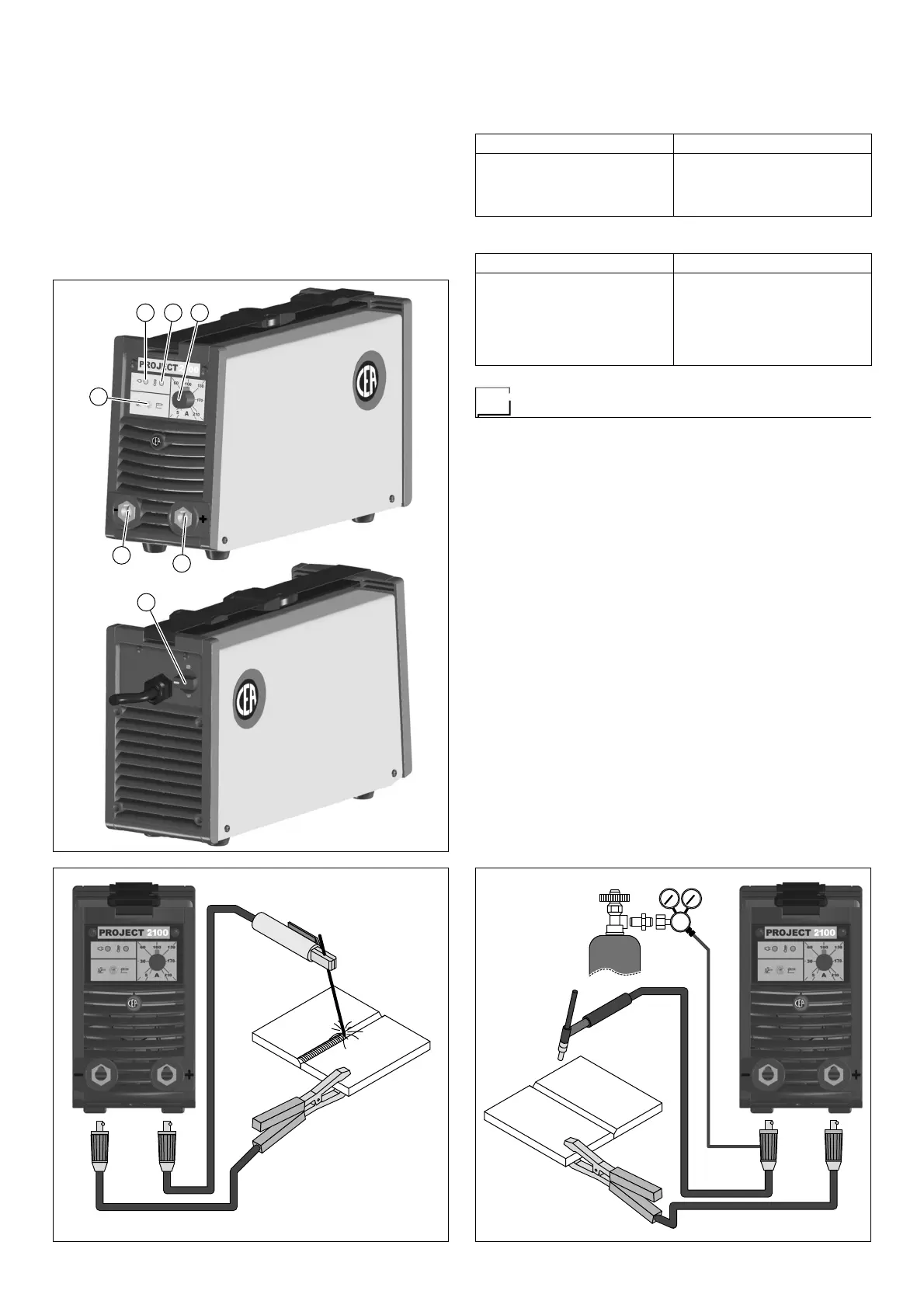

FIG. B

1 2 3

4

5

7

6

FIG. A

2000HB84

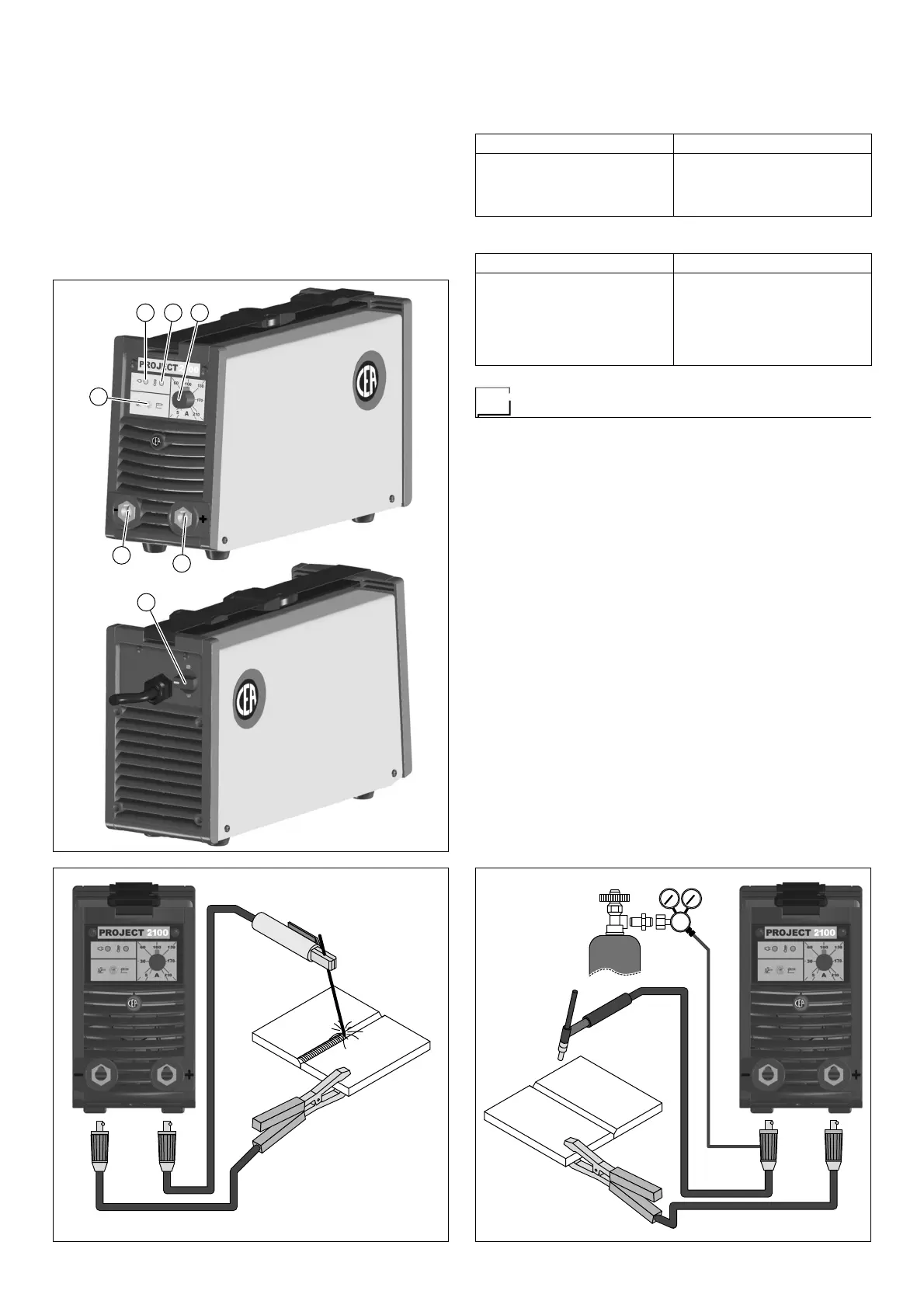

FIG. C

2000HB86

The current intensity to be used for the different types of wel ding,

within the field of regulation shown in table 4 is:

• High for plane, frontal plane and vertical upwards welding.

• Medium for overhead welding.

•

Low for vertical downwards welding and for joining small pre-

heated pieces.

A fairly approximate indication of the average current to use in the

welding of electrodes for ordinary steel is given by the fol lowing

formula:

I = 50 x (Øe - 1)

Where:

I = intensity of the welding current

Øe = electrode diameter

Example:

For electrode diameter 4 mm

I = 50 x (4 -1) = 50 x 3 = 150A

Table 3

WELDING THICKNESS (mm) Ø ELECTRODE (mm)

1,5 ÷ 3

3 ÷ 5

5 ÷ 12

12

2

2,5

3,2

4

Table 4

Ø ELECTRODE (mm) CURRENT (A)

1,6

2

2,5

3,2

4

5

30 ÷ 60

40 ÷ 75

60 ÷ 110

95 ÷ 140

140 ÷ 190

190 ÷ 210

TIG welding (Fig. C)

TIG welding melts the metal of the workpiece, using an arc struck

by a tungsten electrode.

The fusion bath and the electrode are protected by gas (Argon).

This type of welding is used to weld thin sheet metal or when el-

evated quality is required.

1) Connecting the welding cables:

•

Connect one end of the gas hose to the gas connecter on

the TIG torch and the other end to the Argon cylinder and

open it.

• With the machine switched off:

-

Connect the earth cable to the snap-on connector marked

+ (positive).

-

Connect the relative earth clamp to the workpiece or to the

workpiece support in an area free of rust, paint, grease,

etc..

-

Connect the TIG torch power cable to the snap-on con-

nector marked - (negative).

2) Adjust the welding current using the potentiometer (Pos. 3,

Fig. A).

3) Adjust the process switch (Pos. 6, Fig. A) to TIG (switch lever

moved to the left-hand side).

4) Start the welding machine by selecting pos. 1 on the line switch

(Pos. 7, Fig. A).

5) The white LED (Pos. 1, Fig. A) indicates that the welding ma-

chine is powered and ready to work.

6) Adjust the gas flow by manually turning the valve on the TIG

torch.

Loading...

Loading...