5

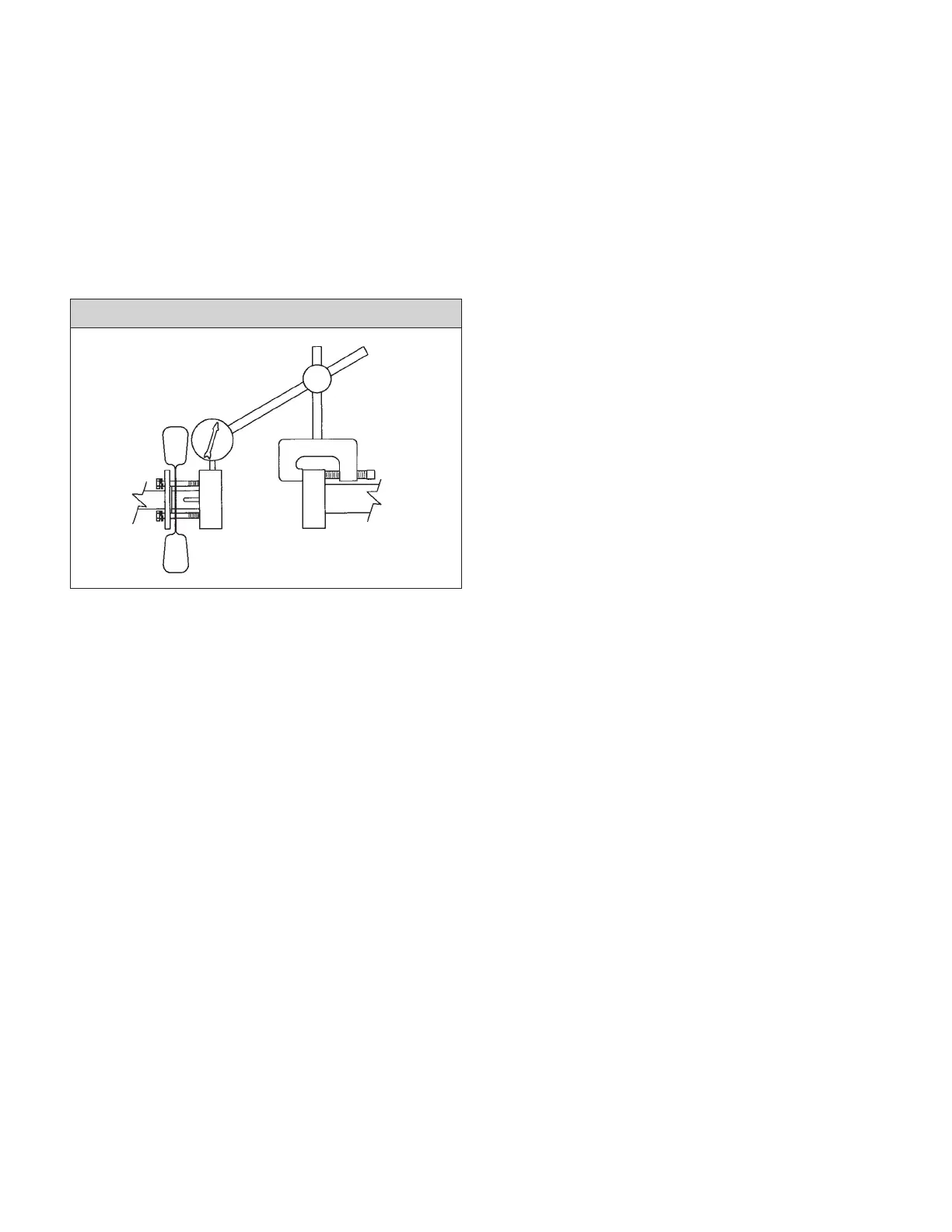

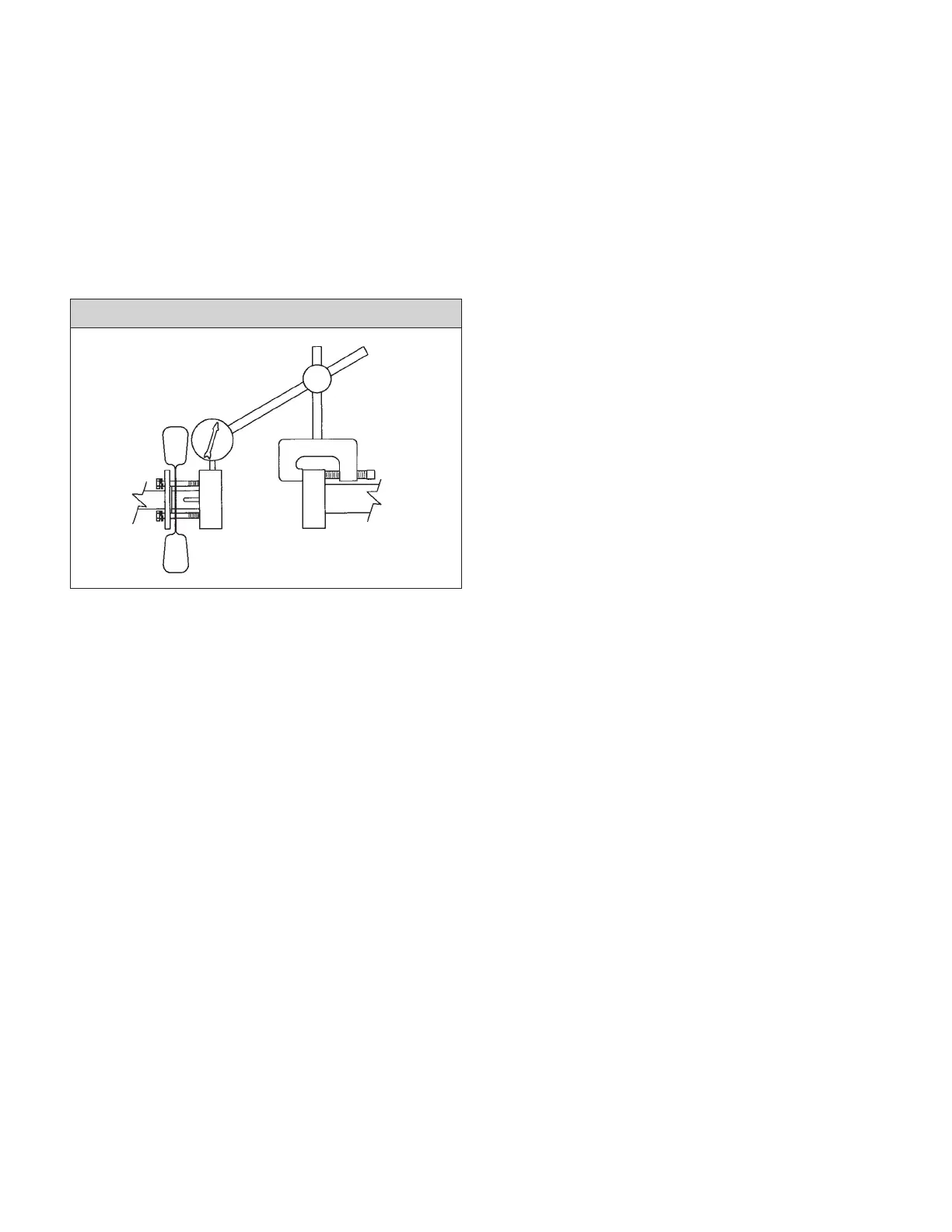

To check the offset alignment, mount the dial indicator as shown in

the illustration “INDICATOR SETUP TO READ OFFSET MISALIGN-

MENT” below, with the indicator button on the outside diameter of

the stationary hub, near the face of the hub closest to the end of the

shaft. It may be necessary, on the RA2096 pumps, to slide the cool-

ing fan (120) closer to the pump, to obtain enough clearance for

the dial indicator, dependent of course upon the type of indicator

used. If necessary, the fan could be removed, and replaced after

the motor alignment is completed. Rotate the shaft, to which the dial

indicator is clamped, allowing the indicator button to ride on the

outside diameter of the stationary coupling hub. The indicator dial

move ment will show the difference in the center locations of the two

shafts. Good practice suggest alignment to within 0.002" T.I.R.

Angular and offset alignment is adjusted by moving the motor side-

ways and up and down to bring the motor into exact alignment

with the bolted down pump. The motor is moved up and down by

adding and removing thin metal shims between the motor feet and

the baseplate. If misalignment is of major proportions, the base-

plate has been improperly installed on the foundation and must be

releveled before proceeding with alignment.

After each change, it is necessary to recheck both angular and off-

set alignment of the coupling. After the pump and driver are

aligned, tighten all hold-down bolts and then recheck alignment.

The closer the running alignment, the longer the running life will be.

INDICATOR SETUP TO READ OFFSET MISALIGNMENT

Loading...

Loading...