Page 17For technical questions, please call 1-888-866-5797.Item 62380

SAFETYOPERATIONMAINTENANCE SETUP

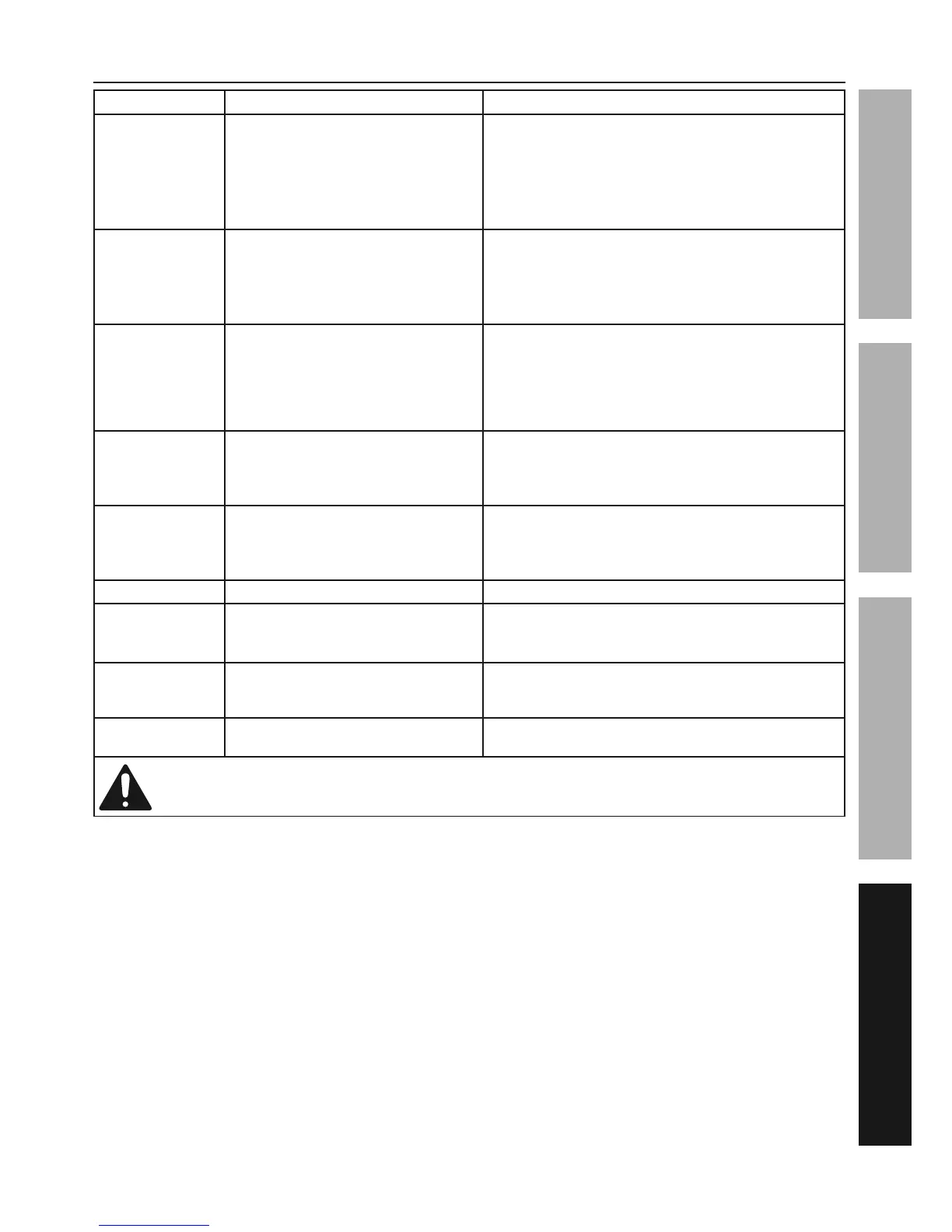

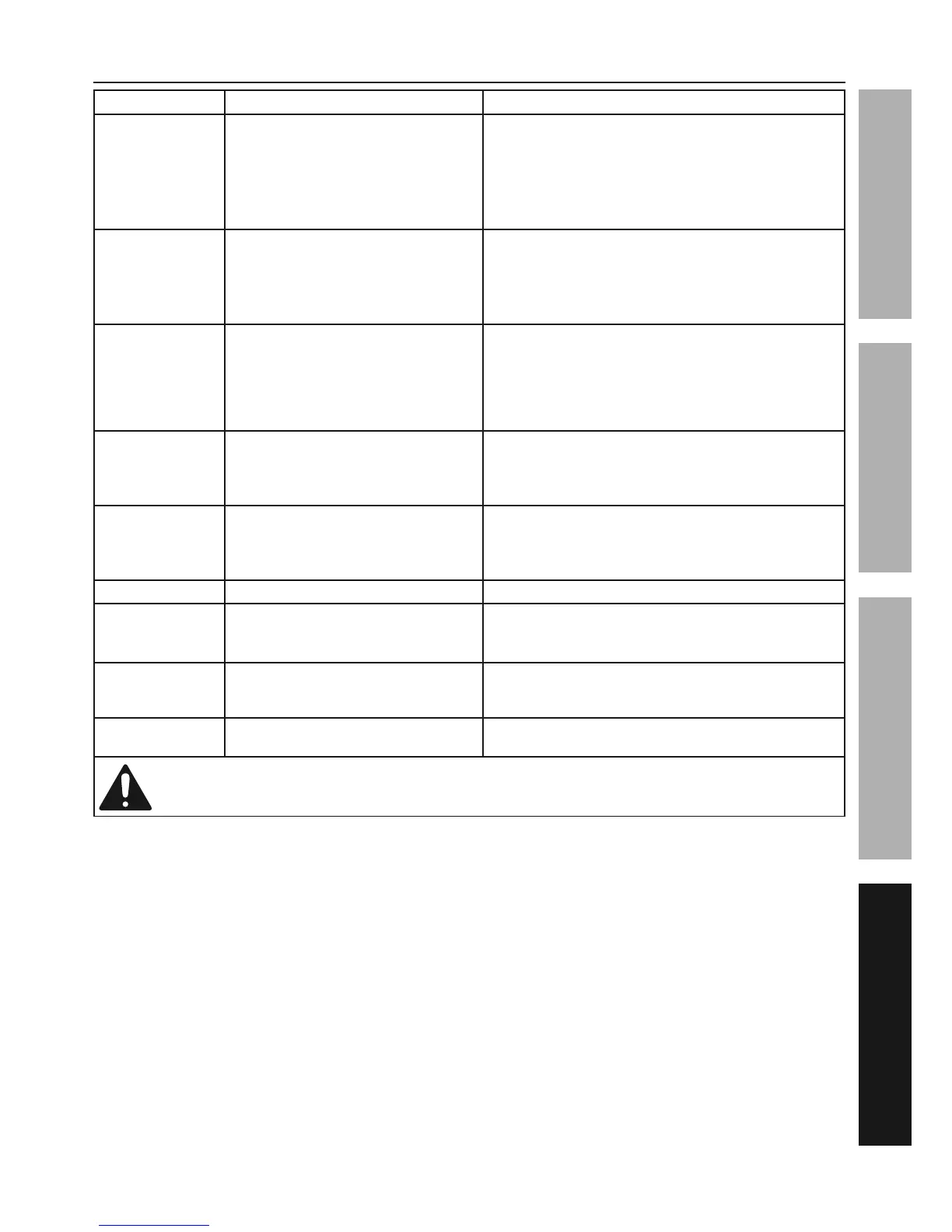

Problem Possible Causes Likely Solutions

Overheating 1� Air filters need cleaning/replacing�

2� Unusually dusty environment�

3� Extension cord used�

4� Unit not on level surface�

1� Check inlet and outlet filters�

Clean and/or replace as needed�

2� Clean and/or replace filters more often or

move unit to cleaner environment�

3� Eliminate extension cord�

4� Reposition unit on a level surface�

Thermal overload

protector cuts

out repeatedly

1� Low voltage�

2� Lack of proper ventilation/

room temperature too high�

3� Wrong gauge wire or length

of extension cord�

1� Check with voltmeter�

2� Move compressor to well-ventilated area�

3� Check for proper gauge wire and cord length�

Compressor

starts and stops

excessively

1� Loose fittings�

2� Compressor not large enough for job�

1� Reduce air pressure, then check all fittings with a soap

solution for air leaks and tighten as needed�

Do not overtighten�

2� Check if accessory CFM is met by Compressor�

If Compressor doesn’t reach accessory CFM,

you need a larger Compressor�

Excessive noise,

vibration

1� Loose fittings�

2� Unit not on level surface�

1� Reduce air pressure, then check all fittings with a soap

solution for air leaks and tighten as needed�

Do not overtighten�

2� Reposition unit on a level surface�

Moisture in

discharge air

1� Too much moisture in air�

2� Excessive water in air

tank High humidity�

1� Install inline air filter/dryer, and/or relocate

to less humid environment�

2� Drain tank Move to area of less

humidity; use air line filter�

Safety Valve “pops” Safety valve needs service� Pull on test ring of safety valve� If it still pops, replace�

Compressor runs

continuously

1� Defective pressure switch�

2� Excessive air usage�

1� Take compressor to qualified technician�

2� Decrease air usage; compressor not large

enough for tool’s requirement�

Air leaks from

pump or fittings

Loose fittings� Reduce air pressure, then check all fittings with a soap

solution for air leaks and tighten as needed�

Do not overtighten�

Air leaks from tank Defective or rusted tank� Have tank replaced by a qualified technician�

Drain moisture from tank daily to prevent future corrosion�

Follow all safety precautions whenever diagnosing or servicing the compressor.

Disconnect power supply before service.

Troubleshooting (cont.)

Loading...

Loading...