Page 16 For technical questions, please call 1-888-866-5797. Item 62380

SAFETY OPERATION MAINTENANCESETUP

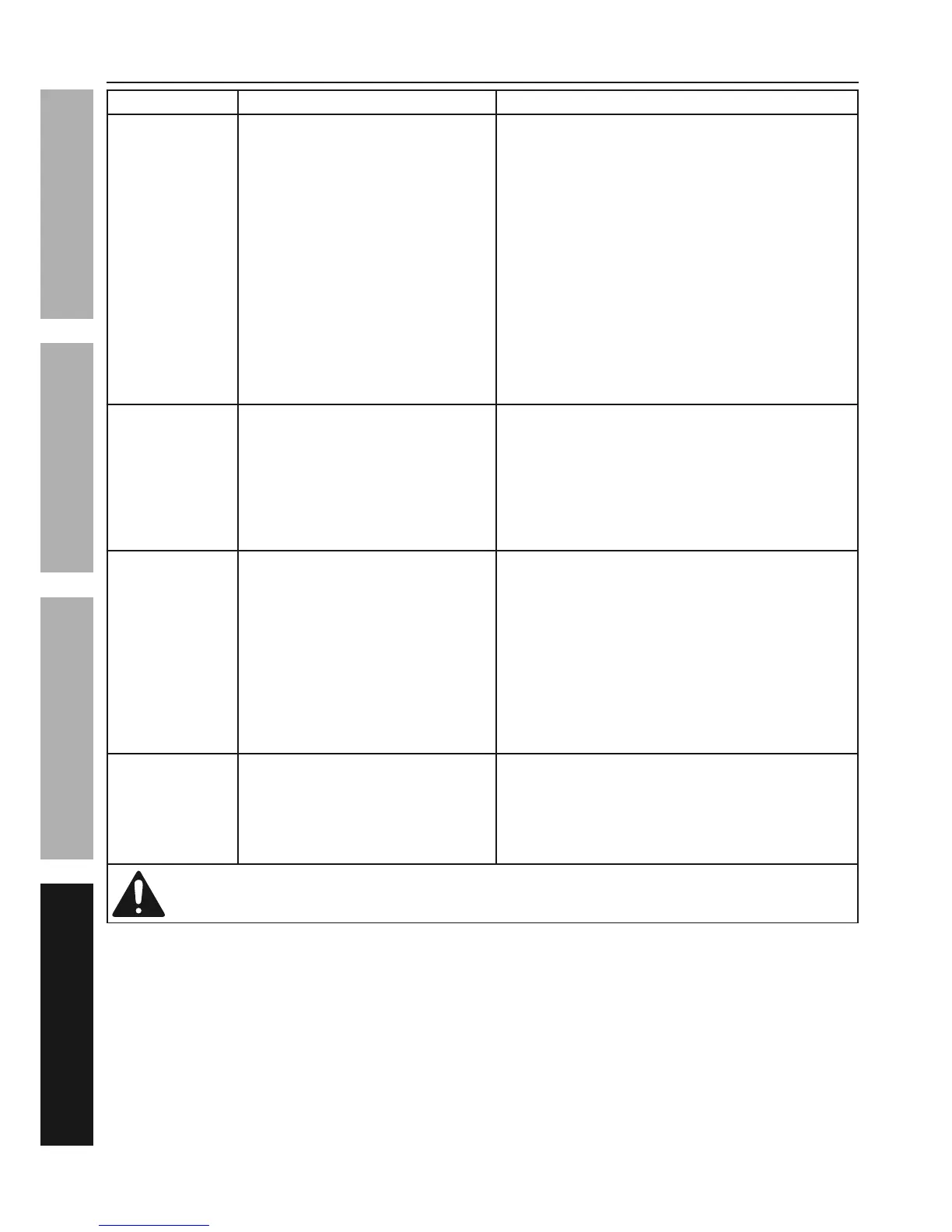

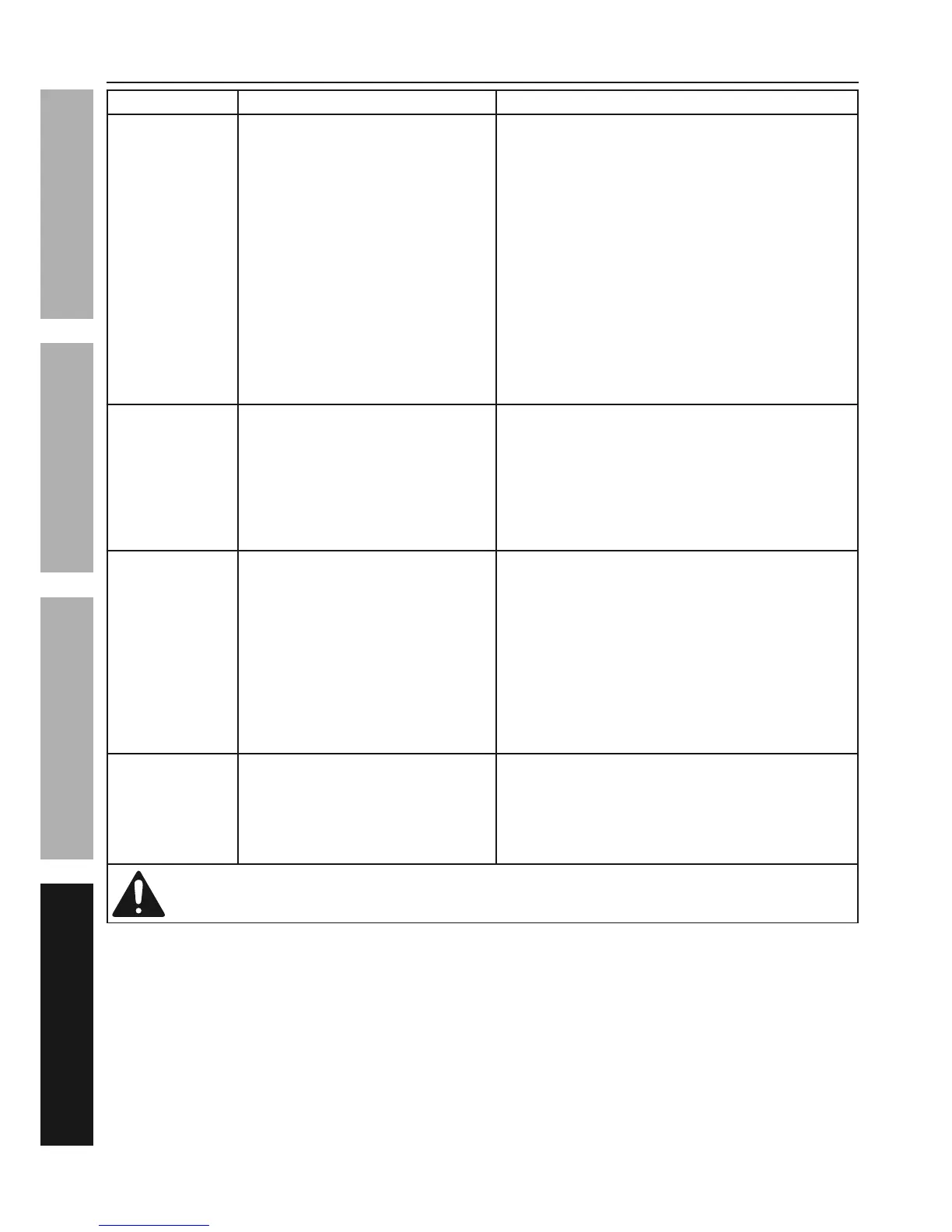

Troubleshooting

Problem Possible Causes Likely Solutions

Compressor does

not start or restart

1� Tank(s) already pressurized�

2� Power cord not plugged in properly�

3� Incorrect power supply�

4� No power at outlet�

5� Thermal overload switch tripped�

6� Building power supply circuit tripped or

blown fuse�

7� Cord wire size is too small or cord is

too long to properly power compressor�

8� Compressor needs service�

1� Check pressure gauges� If pressurized, no

problem� Compressor will start when needed�

2� Check that cord is plugged in securely�

3� Check that circuit matches compressor requirements�

4� Reset circuit breaker, or have outlet

serviced by a qualified technician�

5� Turn off Compressor and wait for it to cool down�

Press reset button� Resume operation�

6� Reset circuit or replace fuse� Check for low voltage

conditions� It may be necessary to disconnect

other electrical appliances from the circuit or

move the compressor to its own circuit�

7� Use larger diameter or shorter extension cord or

eliminate extension cord� See Recommended Wire

Gauge for Extension Cords in Safety section�

8� Have unit inspected by a qualified technician�

Compressor builds

pressure too slowly

1� Incorrect power supply�

2� Working environment too cold�

3� Safety valve leaking�

4� Loose fittings�

1� Check that circuit matches compressor requirements�

2� Move compressor to a warmer location�

3� Listen for air leaking from valve�

If leaking, replace with identical valve with same rating�

DO NOT SEAL OR TAMPER WITH SAFETY VALVE.

4� Reduce air pressure, then check all fittings with

a soap solution for air leaks and tighten as needed�

Do not overtighten�

Compressor not

building enough

air pressure

1� Air filters need cleaning/replacing�

2� Check Valve needs service�

3� Compressor not large enough for job�

4� Loose fittings�

5� Hose or hose connections too narrow�

6� High altitude reducing air output�

1� Check inlet and outlet filters�

Clean and/or replace as needed�

2� Have technician clean or replace, as needed�

3� Check if accessory CFM is met by Compressor�

If Compressor cannot supply enough air flow (CFM),

you need a larger Compressor�

4� Reduce air pressure, then check all fittings with

a soap solution for air leaks and tighten as needed�

Do not overtighten�

5� Replace with wider hose and/or hose connections�

6� Higher altitudes require compressors with greater output�

Fuses blow/

circuit breaker

trips repeatedly

1� Incorrect size fuse, circuit overload�

2� Wrong gauge wire or length

of extension cord�

3� Defective check valve or under loader�

1� Check for proper fuse, use time-delay fuse,

disconnect other electrical appliances from circuit

or operate compressor on its own branch circuit�

2� Check for proper gauge wire and cord length�

3� Take compressor to service center�

Follow all safety precautions whenever diagnosing or servicing the compressor.

Disconnect power supply before service.

Loading...

Loading...