8

Troubleshooting Guide

WARNING! INSPECTION, TESTING, SERVICING AND REPAIR OF THE EXHAUST BLOWER SHOULD BE PER-

FORMED ONLY BY QUALIFIED SERVICE PERSONNEL. THE UNIT SHOULD BE TURNED OFF AT THE DISCON-

NECT SWITCH WHEN SERVICING TO AVOID THE DANGER OF SOMEONE INADVERTENTLY TURNING THE

UNIT ON WHILE IT IS BEING SERVICED. IF ELECTRICAL TESTING IS REQUIRED, EXTREME CARE MUST BE

EXERCISED DUE TO EXPOSED LIVE CIRCUITS!

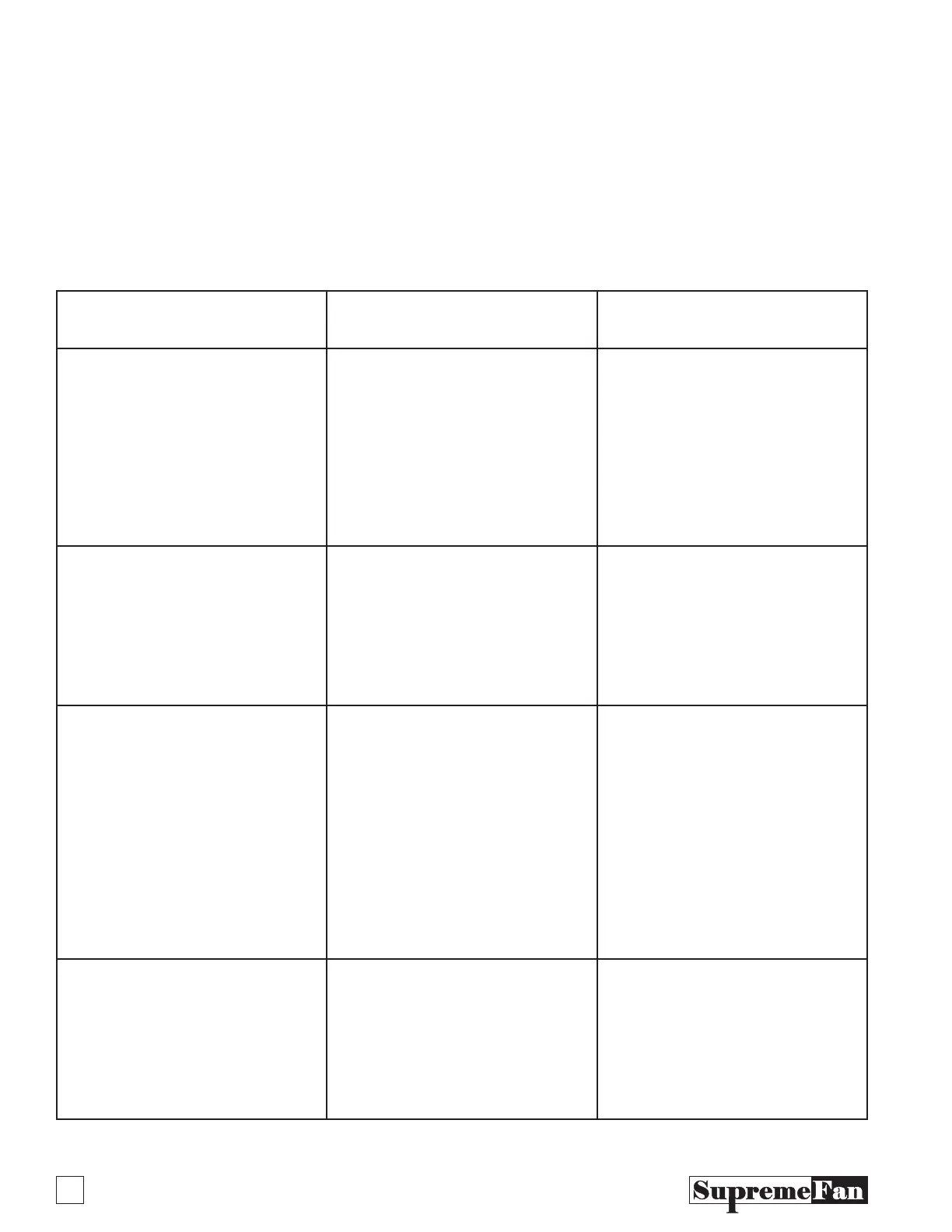

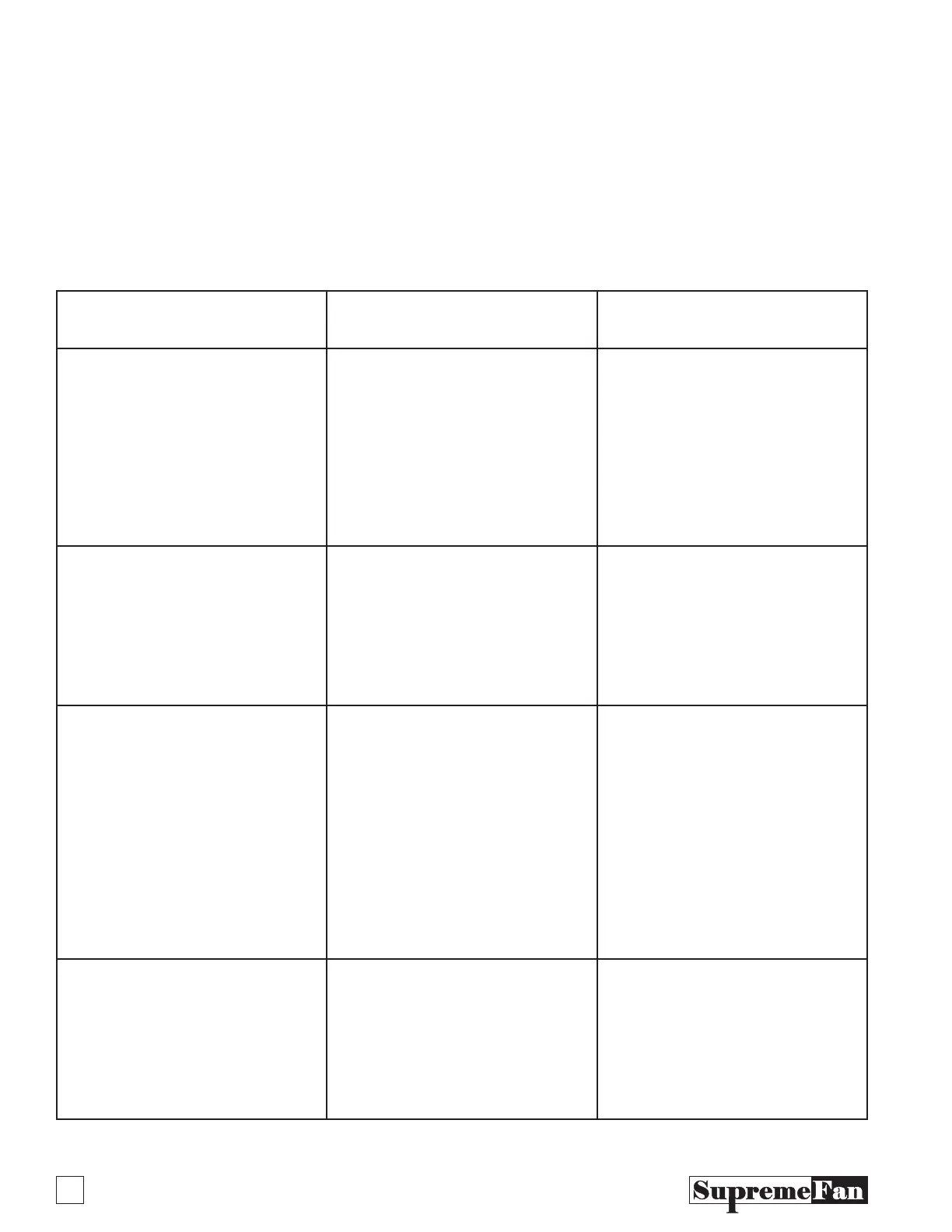

PROBLEM PROBLEM CAUSE CORRECTIVE ACTION

Motor does not run a. Main circuit breaker off

b. Circuit breaker tripped

c. Disconnect switch off

d. Motor starter overloads tripped

e. Fan switch in kitchen turned off

f. Off from interlocking equipment

being off

g. Defective motor

a. Turn on main circuit breaker

b. Reset tripped circuit breaker

c. Turn on disconnect switch

d. Reset starter overloads

e. Turn on exhaust fan switch

f. Turn on interlock equipment

g. Replace motor

Fan does not operate (motor runs) a. Broken belt

b. Seized fan bearings

c. Wheel slipped on shaft and

wedged against intake cone

a. Replace belt

b. Replace bearings

c. Re-position wheel and secure

on shaft

Fan noisy a. Loose parts

b. Bearings need lubrication

c. Cracked belt

d. Defective bearings

e. Locking collar loose on shaft

f. Debris on fan wheel (throwing it

out of balance)

g. Wheel slipped down on shaft,

ticking on intake cone

h. Unbalanced wheel

a. Locate and tighten

b. Lubricate bearings

c. Replace belt

d. Replace bearings

e. Tighten locking collar

f. Remove debris (crew hats,

paper towels, grille slips,

grease build-up, etc.)

g. Re-position wheel and secure

on shaft

h. Replace wheel

Fan cycles on and off a. Motor overloading

b. Defective motor

a. Check F.L.A.-replace with larger

motor if over amps

b. Replace motor

Loading...

Loading...