7

Grease Duct Installation

Side Inlet Fitting (Factory Option)

Grease Duct

Installation Procedure

1. Loosen hinge bolts

securing blower to base.

Lift blower off base. Set

base on roof curb.

2. Drop grease duct through

opening in base. Flanges on

duct will set on lip of base to

hold duct in place.

3. Set blower on base and

tighten bolts that secure

hinges to base.

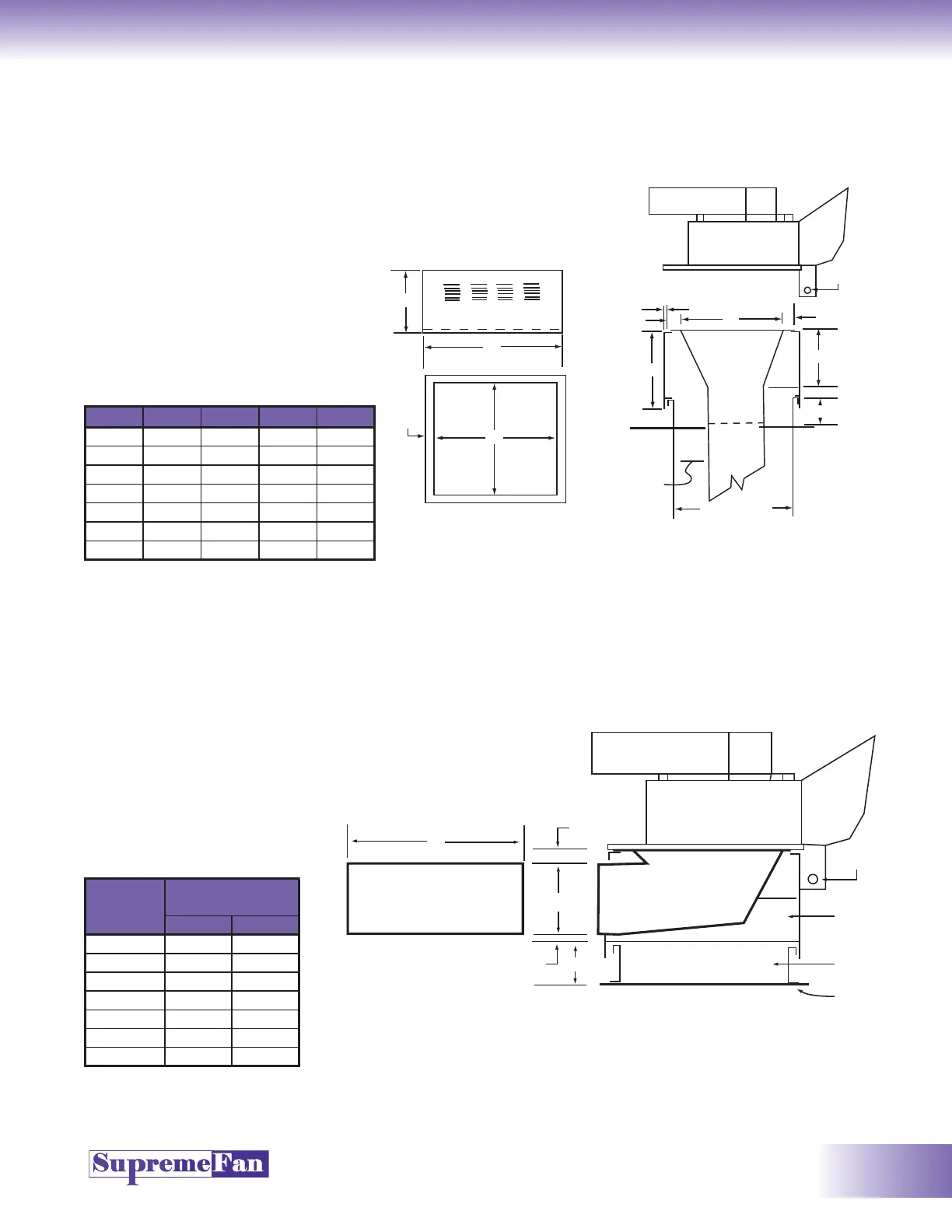

MODEL A B C D

GBD-125

34 31 20 27

GBD-150

34 31 20 27

GBD-182

40 1/2 37 1/2 19 33 1/2

GBD-222

40 1/2 37 1/2 19 33 1/2

GBD-245

47 44 19 40

GBD-270

53 50 19 46

GBD-300

65 1/2 62 1/2 19 58 1/2

When Ordering...

1. Supply A and B dimensions

for proper connection of the

grease duct.

2. Supply C dimension that will

allow proper horizontal duct

run. Duct installation must

conform with NFPA 96 or

local code requirements.

Side View

C

Vented Base

A

1 1/2"

B

Plain View

Exhaust

Blower

Drain

1/2"

3"

D

3"

C

16"

Factory

Optional

Transition

Funnel

Fitting

Roof Line

Grease

Duct by

Others

8"

Clearance

Per Local

Code

Duct Shaft

Factory

Vented

Base

Factory

Optional

Roof Curb

B

3"

A

1/2"

Front View of

Duct Opening

C

Curb Height Will Vary Depending on

Length of Exposed Duct on Roof

Roof Line

Roof Curb

GBD Base

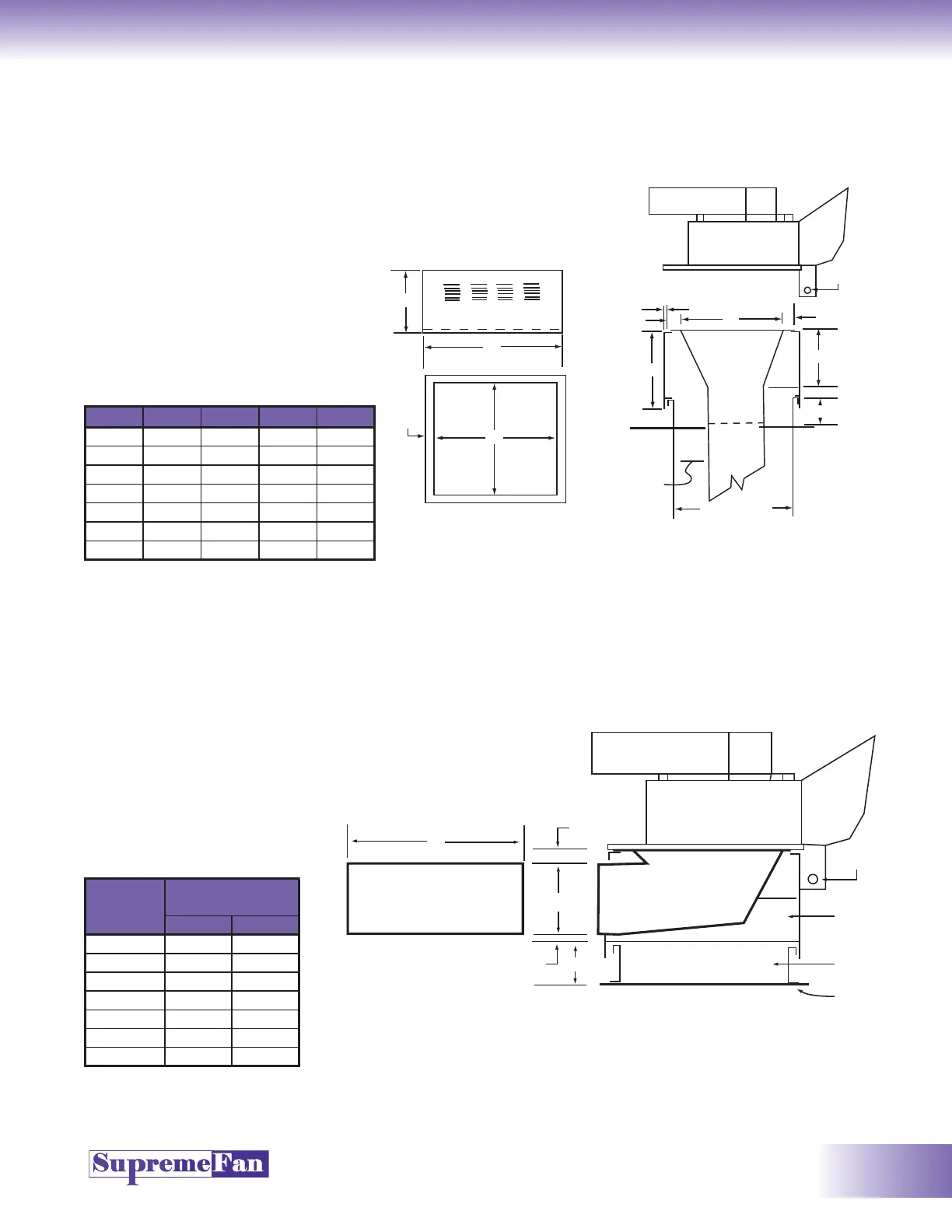

Side Duct

Inlet Fitting

Drain

Exhaust Blower

AB

GBD-125 14 30 1/2

GBD-150 14 30 1/2

GBD-182 14 36 3/8

GBD-222 14 36 3/8

GBD-245 14 43 1/2

GBD-270 14 49 1/2

GBD-300 14 61 7/8

MAXIMUM

DIMENSIONS

MODEL

Loading...

Loading...