10

GBD Lubrication & Maintenance

Prelubricated Bearings

All bearing units are prelubricated with grease chosen

for its chemical and mechanical stability.

Units furnished with a grease fitting should be

periodically relubricated. The relubrication interval

depends on bearing operating conditions including

speed, temperature and environment:

The fan bearings are supplied with premium lithium

complex NLGI #2 bearing grease.

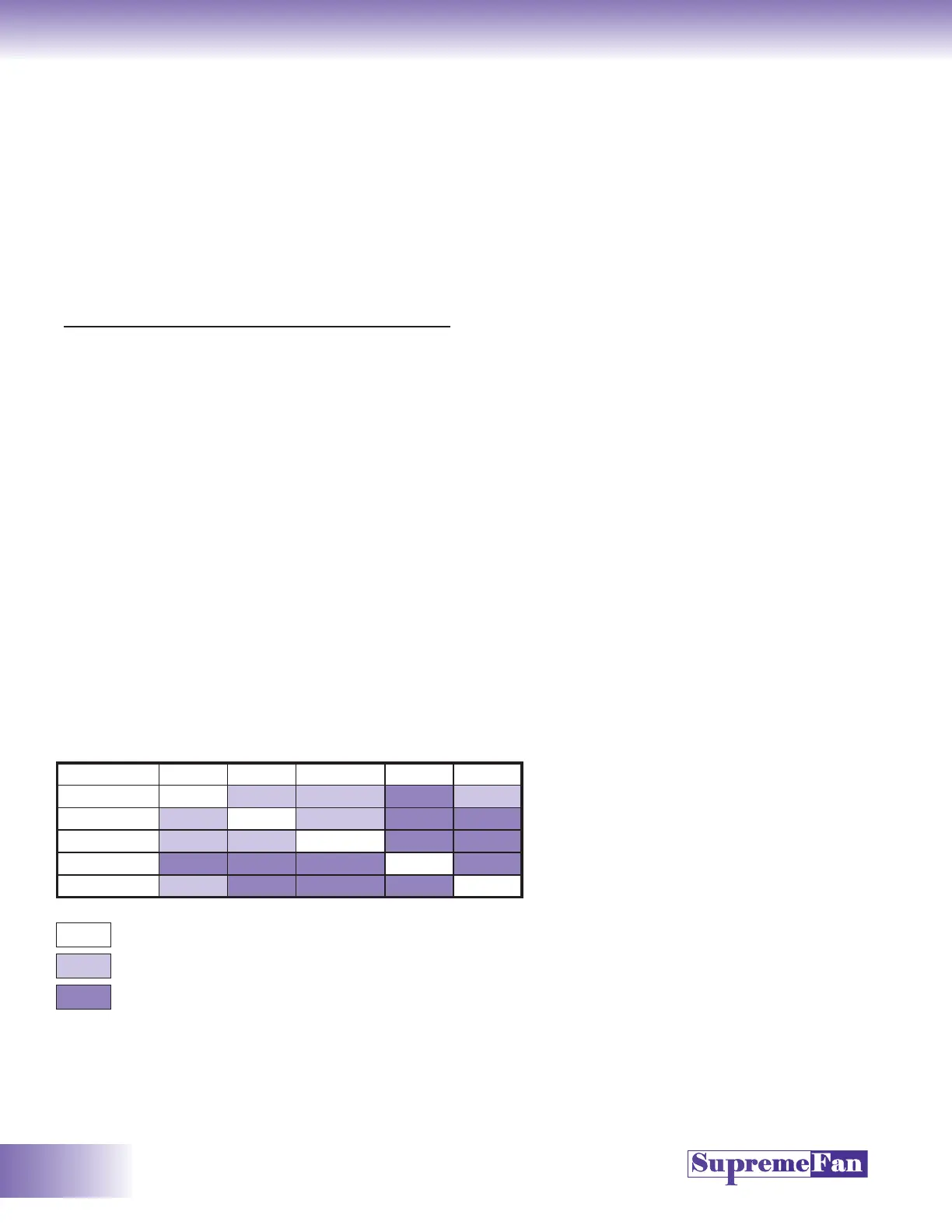

Mixing different kinds of grease can greatly affect the

viscosity, dropping point and penetration properties of

the lubricant. Water and heat-resisting properties and

mechanical stability are lowered. It is essential that the

thickener (soap base), NLGI penetration grade and the

base oil be of the same group. See the chart below for

the mixing properties of grease.

Maintenance Procedures

The exhaust blower should be inspected every three

months as follows:

1. Check the blower wheel; it lifts out of the scroll on

GBD models. If grease laden, clean to insure quiet

and efficient operation.

2. Check belt tension and wear; replace belts if wear is

excessive.

3. Motors are equipped with prelubricated ball bearings,

and will require no lubrication for normal operation.

4. Exhaust blower wheel ball bearings are equipped with

grease fittings. Grease per instructions on left.

Relubrication Procedure

1. Add grease slowly with shaft rotating until a slight bead

forms at the seals.

2. Relubrication is generally accompanied by a slight rise

in operating temperature until the bearing chamber is

stabilized with the proper amount of grease.

3. If necessary to relubricate while bearing is stationary,

refer to bearing manufacturer’s specifications for

maximum grease capacity for size of bearing.

4. For abnormal operating conditions of high temperature

or abnormal environments, consult the factory.

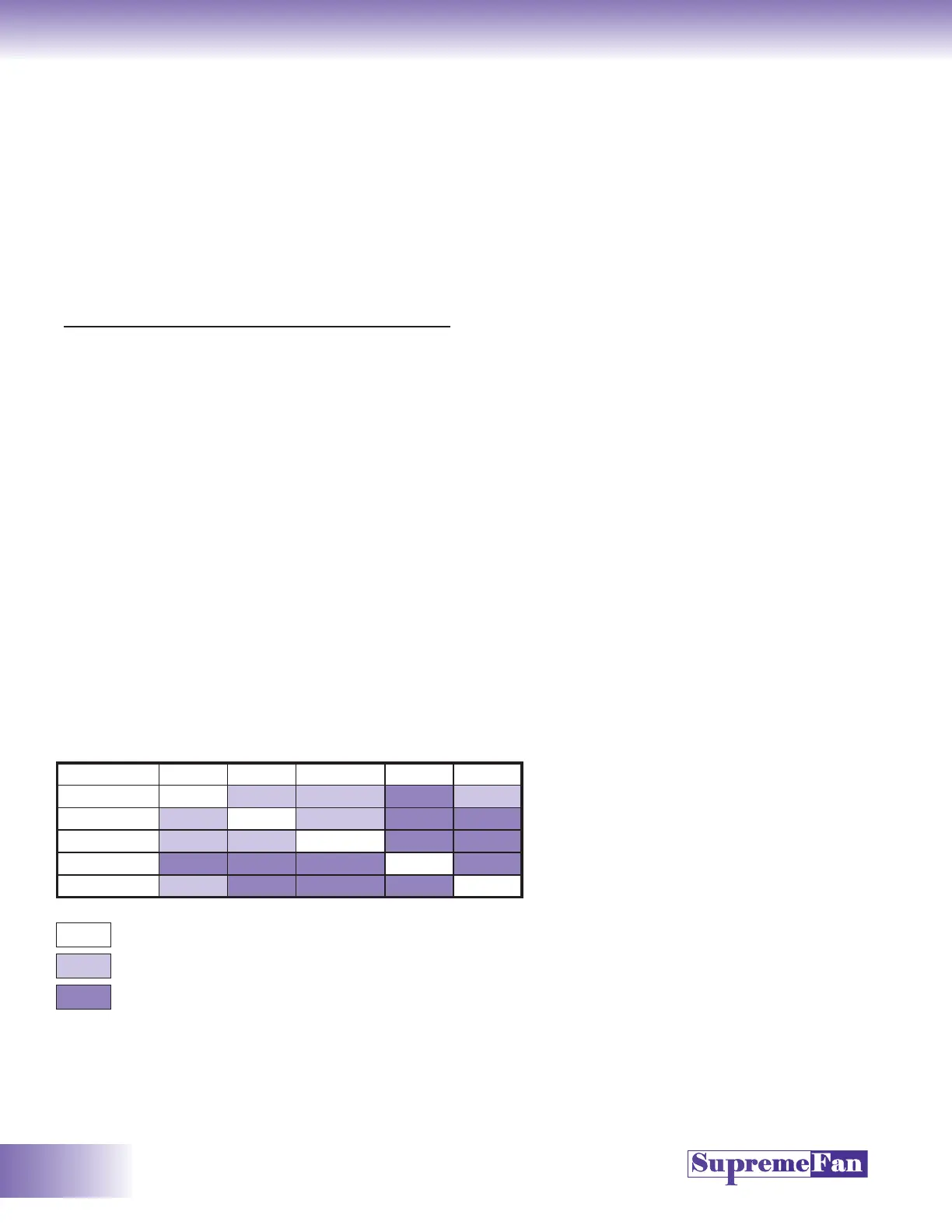

Speed

(RPM)

Temperature

(°F)

Type of

Enviroment

Greasing

Interval

to 500 up to 120°F clean 6 months

to 1000 up to 150°F clean 6 months

to 1500 up to 210°F clean 5 months

to 2000 over 210°F clean 4 months

any up to 150°F dirty 5 months

any over 150°F dirty 4 months

any any extreme 3 months

Mixing Properties of Grease

SOAP BASE CALCIUM SODIUM ALUMINUM BARIUM LITHIUM

CALCIUM

+• • x•

SODIUM

•+ • xx

ALUMINUM

•• + xx

BARIUM

xx x +x

LITHIUM

•x x x+

+

Mixing will not produce appreciable changes of properties.

•

Mixing may produce considerable changes of properties.

X

Mixing will cause a drastic change of properties.

Loading...

Loading...