1-3

F.352-KO/EH-3C DRILL/AUG 03

1.0 INSTALLATION & SETUP

Note: Further adjustments may be necessary once the

machine is ready to drill. See Table Position Adjust-

ment (section 4.3.1).

1.3 INSTALLING THE DRILL BLOCKS

AND DRILLS

Place the drill block knock-outs in position (refer to fig.

1-1 if necessary). Now set the three drill blocks place.

Check to see if the blocks are flush with the table. Place

shims under the blocks if necessary.

Insert the tapered head of the hollow drills into the

spindles. Be sure that the drift hole covers are in place

before operating the machine (fig 1-1). The drift hole

covers prevent paper chips from flying out while drilling.

1.4 HYDRAULIC LEVEL CHECK

Check the level of the oil in the hydraulic reservoir. This

check is made by first removing the louvered panel at

the left side of the stand (two screws hold it in place)

and locating the breather cap on the top of the reservoir.

The breather cap has a dip stick attached for checking

the oil. When screwed in (and then removed to check)

there should be approximately an 1/8” (3 mm) of oil on

the stick. Some machines are equipped with a clear

reservoir in which case the oil level can be checked by

visually inspecting the oil level. There is a full level line

marked on the reservoir. Recommended oils are found

in the maintenance section of this manual (section

4.5.1).

1.5 HOOKING UP THE POWER LINE

The EH-3C is factory wired for 208/230 Volt, 1 phase,

50/60 hz. operation. It is the customer’s responsibility

to wire the machine for the rated voltage using a 30

Amp circuit (minimum). The recommended circuit over-

load protection device should be 20 Amps. The recom-

mended wire size for this hookup is #10 gauge.

CAUTION: Always disconnect the

power when cleaning, servicing, or

lubricating your drill, see Lock Out Pro-

cedures, page v.

CAUTION: Always handle drills with

care to avoid severe lacerations. Even

dull drills are sharp enough to cause

lacerations.

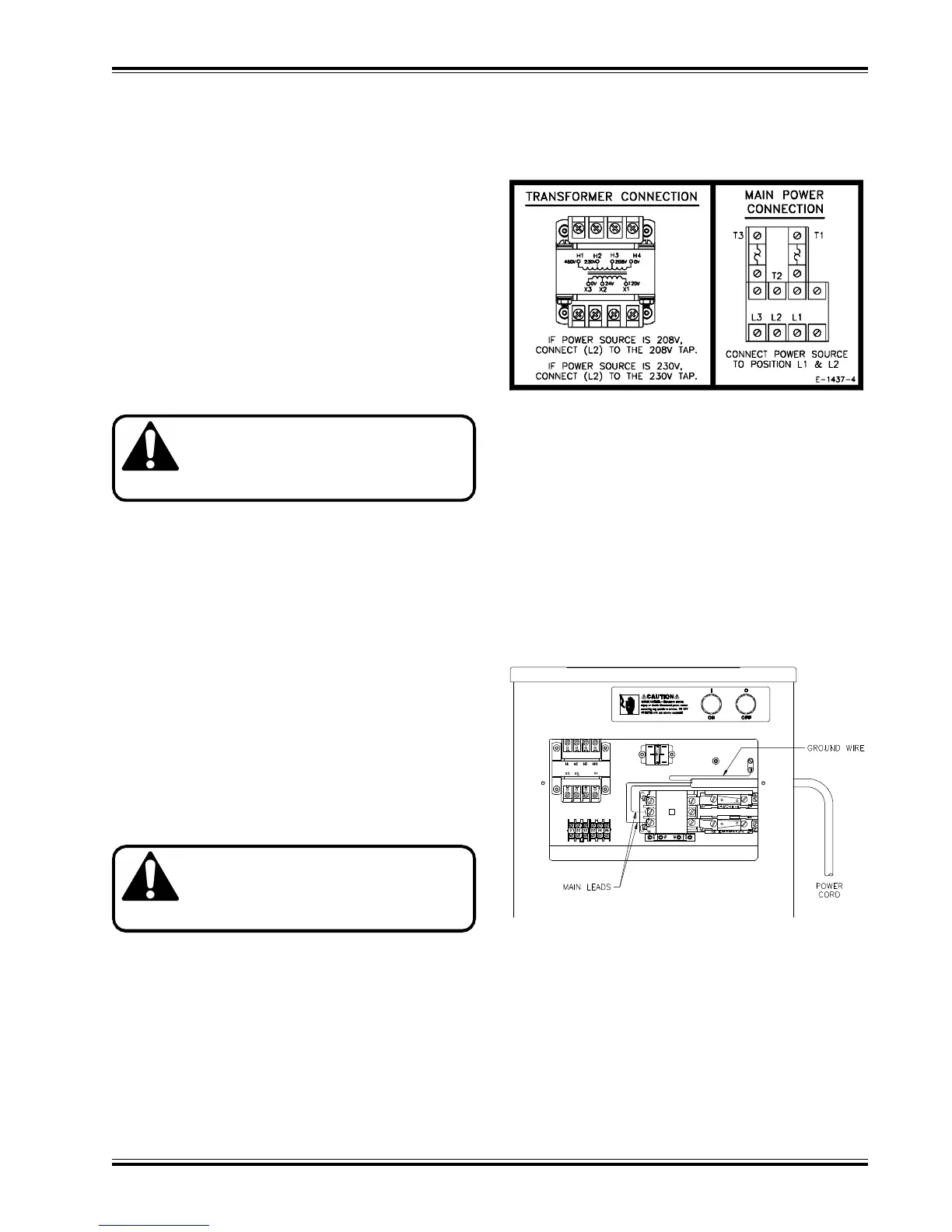

(fig. 1-6)

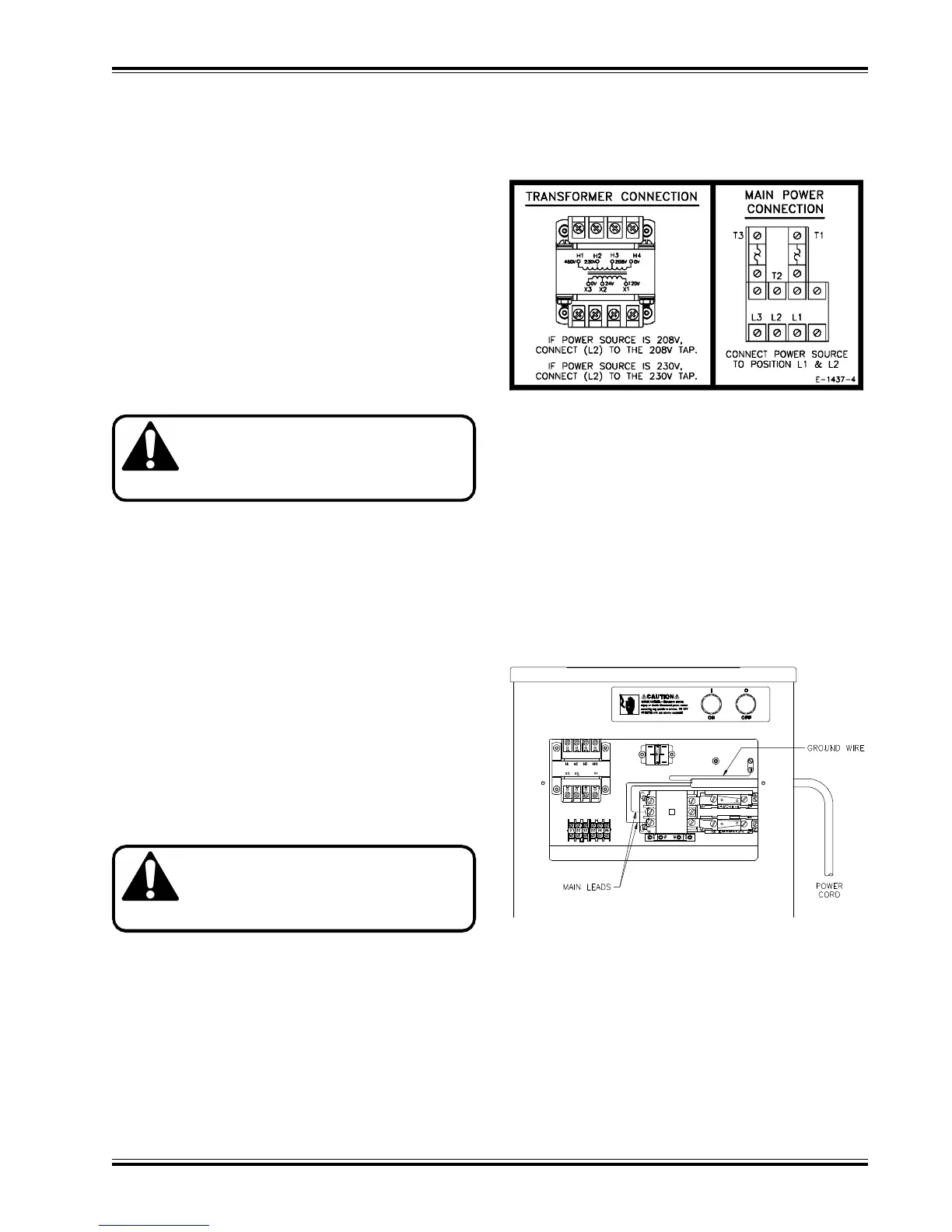

(fig. 1-7)

IMPORTANT: Select the proper transformer primary

tap 208 or 230 Volts to match the voltage supplied

to the machine (fig. 1-6).

It is also important that the proper line voltage be main-

tained. Failure to do so will result in improper operation

of the machine (see the troubleshooting section of this

manual for specific problems). It may be necessary to

provide a separate branch power line for the machine.

Since the standard machine is intended for a single

phase hookup, simply fasten either wire of the power

cord to either terminal of the starter and the ground wire

to the designated terminal (fig. 1-7).

1.6 INSTALLING THE CHIP CONTAINER

The chip container is installed by slipping it over the two

hooks provided on the rear of the machine.

Loading...

Loading...