7 . ACCESSORIES AND OPTIONS

7.84

Challenger MT500B EU

NOTE: In this section, explanations shall be illustrated

by a disc tiller example.

IMPORTANT: If this implement is hitched to the tractor

lift arms, the linkage must first be set to working posi-

tion and then the TIC menu must be activated (activa-

tion of the TIC menu locks the linkage).

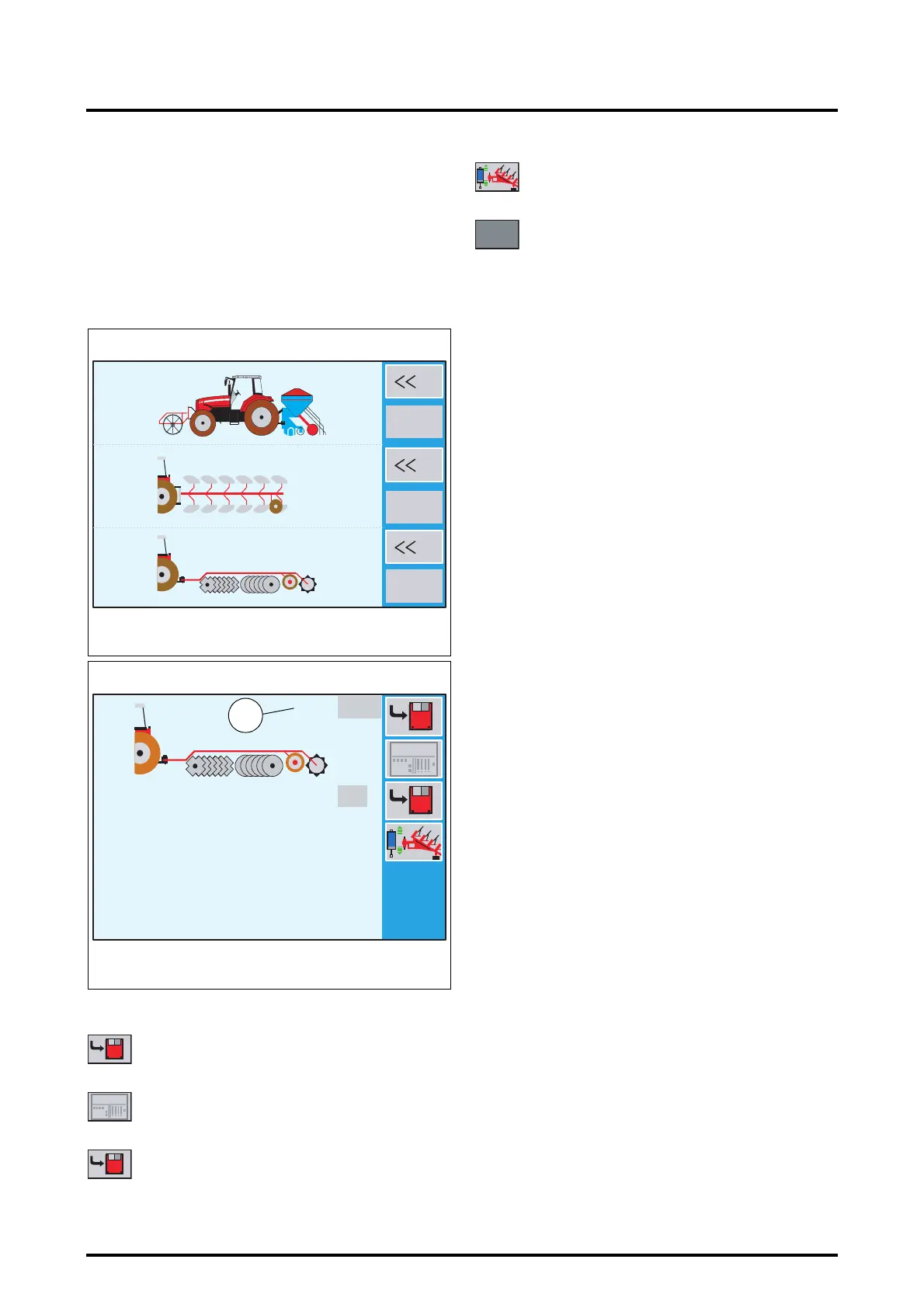

When the window (Fig. 204) is open, press the key «

5

. The

window (Fig. 205) is displayed.

Description:

NOTE: The values that are not in boxes correspond to

instant values.

7.14.0.1 - Calibration

The TIC is operated by the Datatronic which receives infor-

mation from a position sensor located on the rear linkage.

However, for the DUAL CONTROL to operate correctly,

the rear implement position sensor must be calibrated. The

calibration procedure is identical to that described in

paragraph 7.8.3.1. (Calibration).

IMPORTANT: This operation must be performed on

first use, or as soon as work is carried out on the rear

implement position sensor.

NOTE: If a memory is active, the calibration is stored in

this memory.

NOTE: As with the FRONT and REAR DUAL CONTROL,

the calibration can be downloaded into different mem-

ories. The procedure is set out in paragraph 7.8.2.2.

(Downloading the calibration).

7.14.0.2 - Memorising the disc tiller high and low posi-

tions

For optimum operation, the DATATRONIC must know the

disc tiller high and low positions. For this purpose, the im-

plement hitched to the swinging drawbar must be fitted

with a position sensor connected to the rear of the tractor.

.

Memorising the high position:

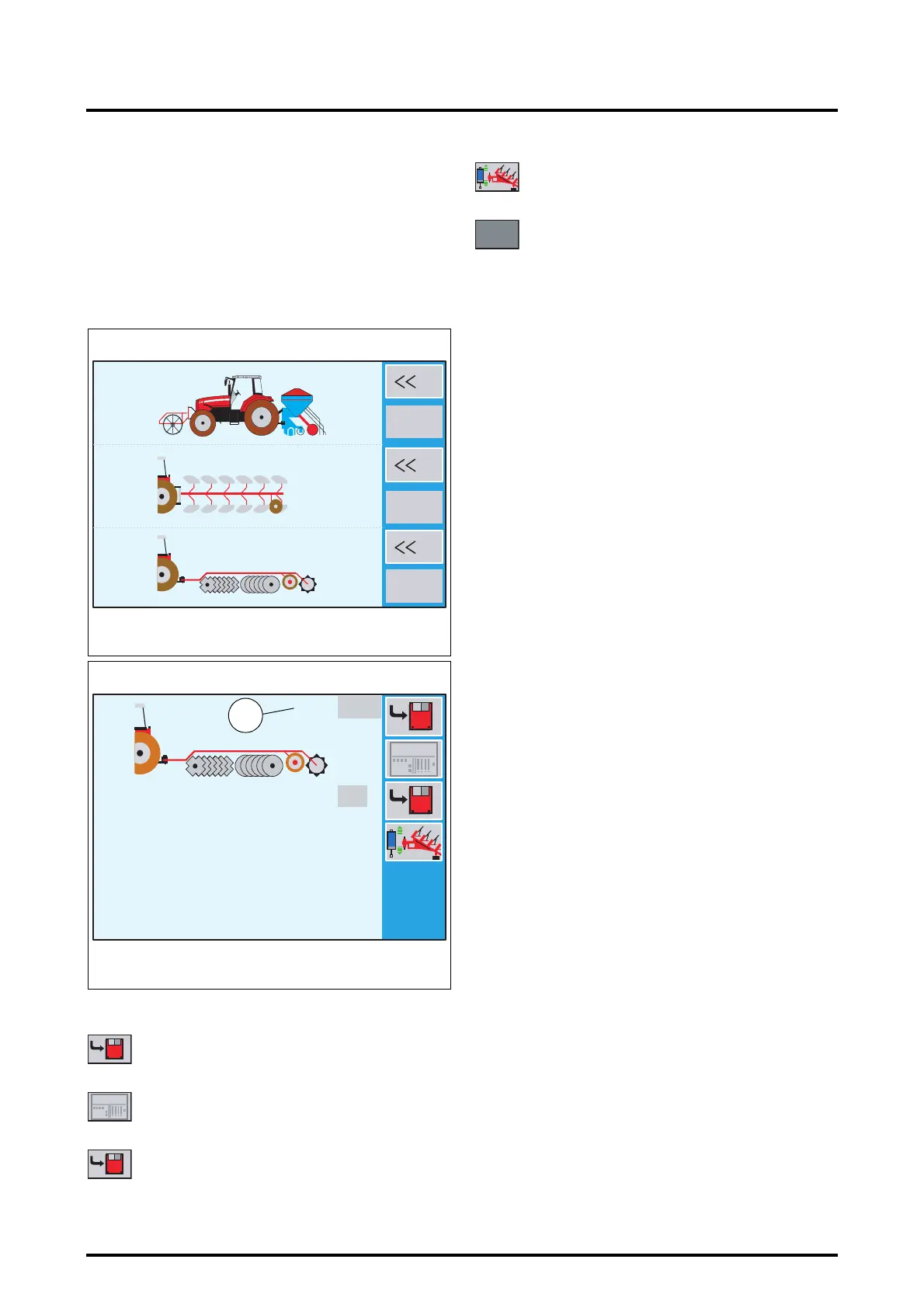

• Place the disc tiller in high position (Fig. 206) using a

linkage cylinder spool valve control.

When the spool valve control is actuated, the high position

value varies (68 Fig. 205).

Memorises high implement position

Displays the TIC menu in the Work application

Memorises low implement position

Z3A-817-08-04

1

5

3

?

?

?

Fig. 204

100%

0%

0%

100%

1920

42.0

Z3A-804-08-04-B

Fig. 205

68

1920

42.0

Opens the sensor calibration menu

Greyed boxes: memorised values

Loading...

Loading...