c

2000, The Chamberlain Group, Inc.

All rights Reserved

01-17781A

RECOMMENDED POWER AND CONTROL CONNECTIONS

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

CONNECTED IN ACCORDANCE WITH LOCAL ELEC-

TRICAL CODES. NOTE: THE OPERATOR SHOULD

BE ON A SEPARATE FUSED LINE OF ADEQUATE

CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

Before installing power wiring or control stations be sure to follow all specifications and warn-

ings described below. Failure to do so may result in severe injury to persons and/or damage to

operator.

For best protection against the environment follow directions below for recommended specifi-

cations for power and control wiring connections.

SUGGESTED CONDUIT & FITTINGS

Liquidtight Flexible Nonmetallic Conduit is permitted

for use in both exposed and concealed areas and for

electrical systems that require flexibility and protection

from vapors, liquids or solids.

LFNC conduit should be used for Liquidtight environ-

ments as stated by NEMA guidelines.

All conduit and conduit fittings should be marked as

“Liquidtight”, conduit and fittings marked “Raintight” or

“Wet Locations” are not to be automatically consid-

ered liquidtight.

NOTE: Select all conduit and conduit connectors

based on local code and application of job.

CONDUIT & FITTING PREPARATION

The most efficient assembly of a liquidtight conduit

and fitting system can be achieved, and optimum per-

formance ensured, by adherence to simple conduit

preparation and assembly techniques:

1. Square off ends of conduit by cutting the end of the

conduit squarely using a hacksaw or similar tool, con-

duit manufacturers sometimes offer cutting jigs for this

purpose.

2. Fully insert conduit flush with the fitting end stop.

3. Secure conduit to fitting. A compression gland nut,

when supplied as part of a fitting, will typically achieve

maximum securement.

4. Ensure conduit jacket is not cut or ripped in any

location along its surface.

NOTE: For conduit preparation, always follow the

conduit manufacturers instructions.

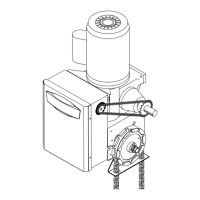

ATTACHMENT TO ENCLOSURE

1. Select proper fitting entry hole to be placed in

enclosure and punch through using drill or tool sup-

plied by manufacturer.

2. Slide threaded body into fitting hole in enclosure.

3. Insert gasketing around threaded area and secure

in place with nut supplied. (Refer to manufacturer

specifications for proper torque requirements).

NOTE: For fitting attachments, always follow the

manufacturers instructions.

ANY MAINTENANCE TO THE OPERATOR OR IN THE

AREA NEAR THE OPERATOR MUST NOT BE PER-

FORMED UNTIL DISCONNECTING THE ELECTRICAL

POWER VIA, THE MAIN DISCONNECT SWITCH.

UPON COMPLETION OF MAINTENANCE THE AREA

MUST BE CLEARED AND SECURED, AT THAT TIME

THE UNIT MAY BE RETURNED TO SERVICE.

Loading...

Loading...