GB

52

CN

GR

FR

SP

PT

Positioning of the ignition and flame

sensing electrode

Figure 14

9912070100

Electronic board calibration

When the jumper or the switch is in the (g. 13a) position:

GPL operation of system with NATURAL gas

T-off 3-minute heating stand-by time

When the jumper or the switch is in the (g. 13b) position:

GPL

operation of system with LPG

T-off 10-seconds heating stand-by time

020521_0400020521_0300

Figure 13b

Figure 13a

NB Make sure that electrical power supply has been disconnected before making

settings.

Graph 1

0303_2403

Check of combustion parameters

The boiler has two connection points specically designed to allow technicians to

measure the combustion efciency after installation and ensure that the combustion

products do not constitute a health risk, as required by Italian Presidential Decree n.

412 of 26

th

August 1993.

One connection point is connected to the ue gas discharge circuit, and allows monitoring

of the quality of the combustion products and the combustion efciency.

The other is connected to the combustion air intake circuit, allowing checking of any

recycling of the combustion products in case of coaxial pipelines.

The following parameters can be measured at the connection point on the ue gas

circuit:

• temperature of the combustion products;

• oxygen (O2) or carbon dioxide (CO2) concentration;

• carbon monoxide(CO) concentration.

The combustion air temperature must be measured at the connection point on the air

intake circuit, inserting the measurement probe to a depth of about 3 cm.

For natural draught boiler models, a hole must be made in the ue gas discharge pipe at

a distance from the boiler equal to twice the inside diameter of the pipe itself.

The following parameters can be measured through this hole:

• temperature of the combustion products;

• oxygen (O2) or carbon dioxide (CO2) concentration;

• carbon monoxide (CO) concentration.

The combustion air temperature must be measured close to the point where the air

enters the boiler.

The hole, which must be made by the person in charge of operating the system when it

is commissioned, must be sealed in a way which ensures that the combustion product

discharge pipe is airtight during normal operation.

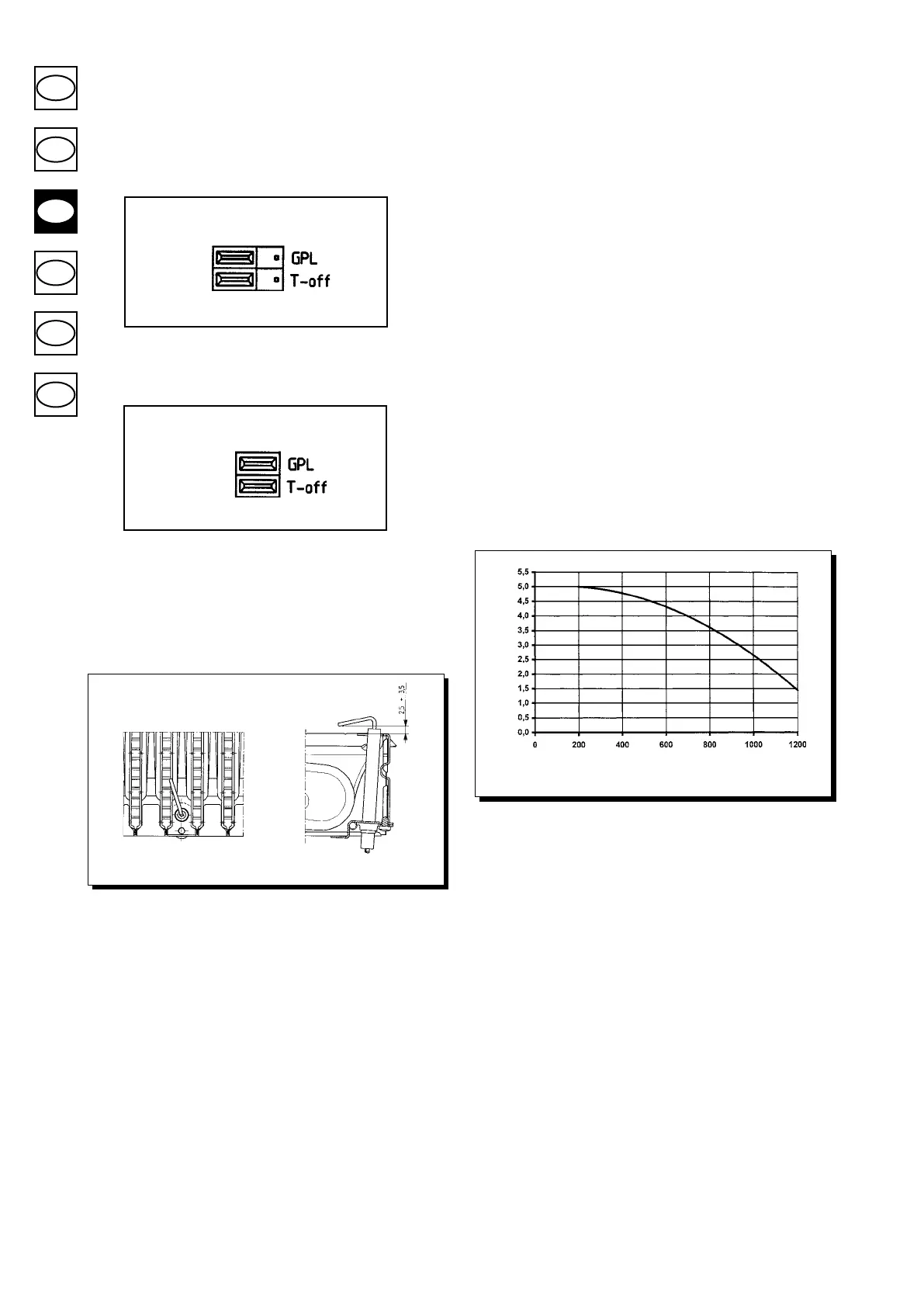

Output / pump head performances

This is a high static head pump t for installation on any type of single or double-pipe

heating systems. The air vent valve incorporated in the pump allows quick venting of

the heating system.

OUTPUT l/h

PUMP HEAD mH

2

O

Loading...

Loading...