45

GB

CN

GR

FR

SP

PT

Flue duct terminal

Coaxial

V

ertical two-pipe

Horizontal two-pipe

Outer

duct

diameter

100

mm

80 mm

80 mm

Max. length

of flue duct

5

m

15 m

30 m

Each 90° bend

reduces the duct

max. length by

1 m

0,5 m

0,5 m

Each 45° bend

reduces the duct

max. length by

0,5 m

0,25 m

0,25 m

Flue

terminal

diameter

100

mm

133 mm

-

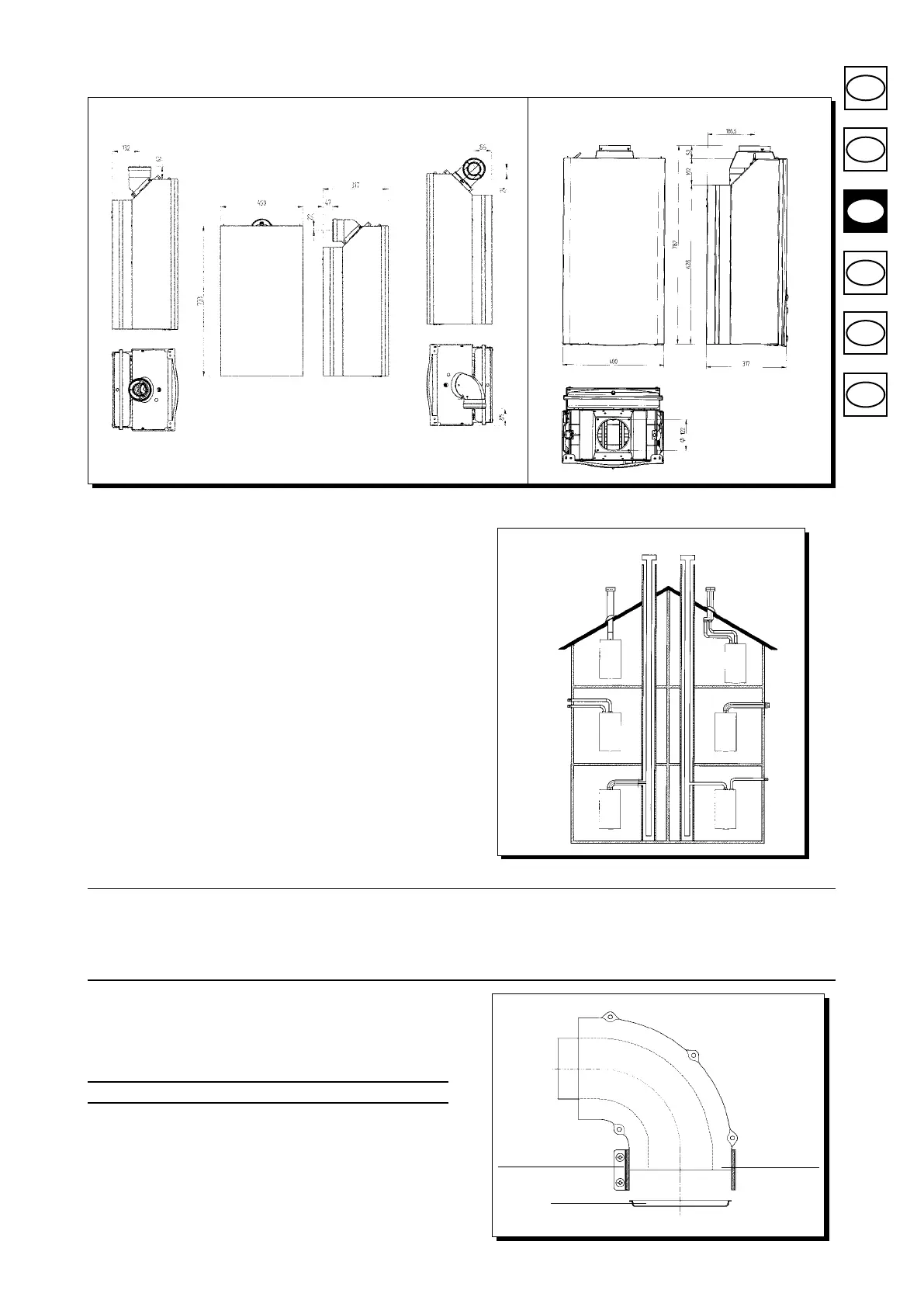

Figure 6

Boiler size

2.24 CF 2.24 FF

Installation of flue and air ducts

(2.24 CF)

We guarantee ease and exibility of installation for a gas-red forced draft boiler thanks

to the ttings and xtures supplied (described below).

The boiler is especially designed for connection to an exhaust ue / air ducting, with

either coaxial, vertical or horizontal terminal. By means of a splitting kit a two-pipe system

may also be installed.

Exclusively

install fittings supplied by the manufacturer.

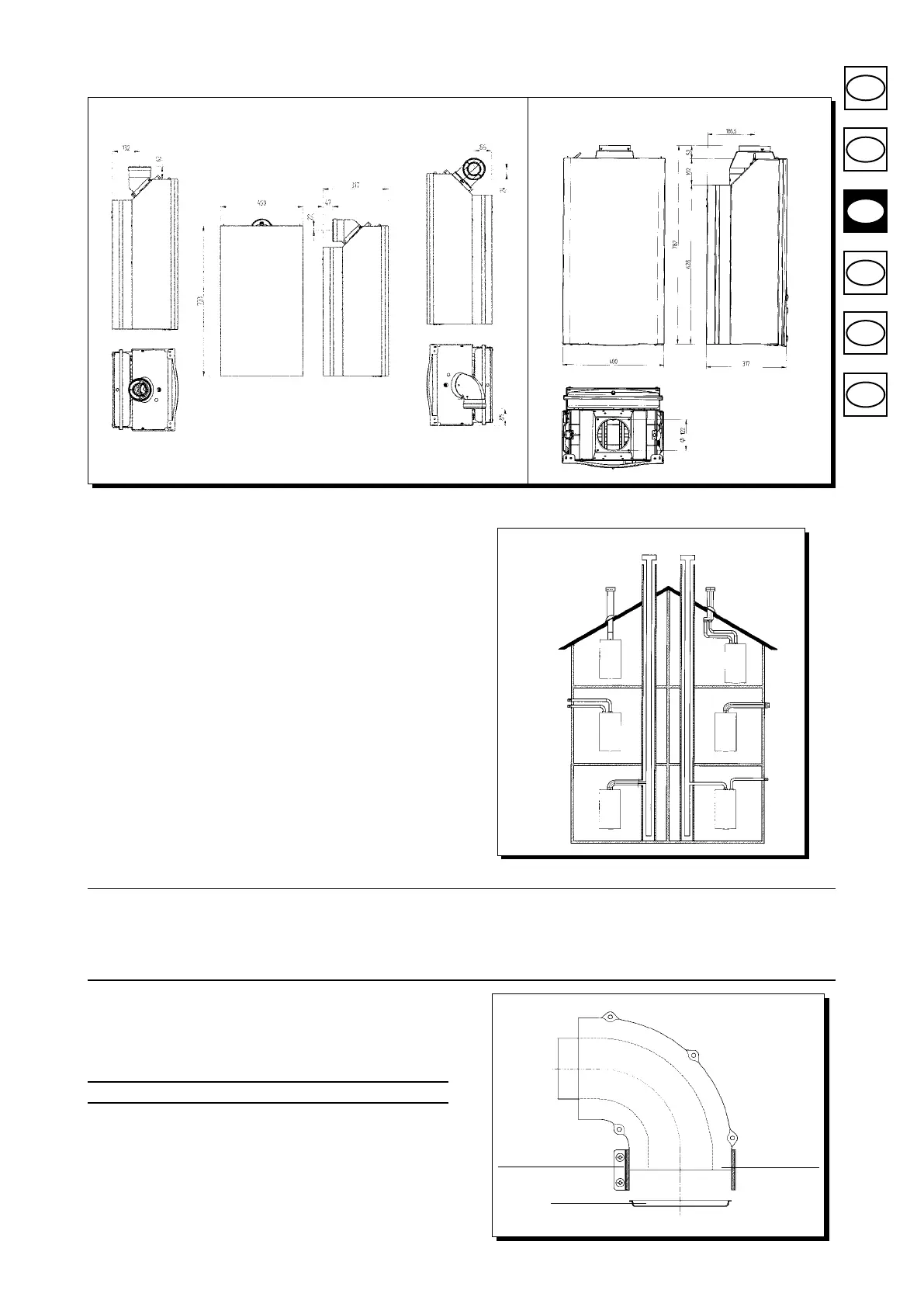

Figure 7

020221_1200

securing clamp

seal

r

estrictor (*)

Figure 8

...coaxial flue - air duct (concentric)

This type of duct allows to disengage exhaust gases and to draw combustion air both

outside the building and in case a LAS ue is tted.

The 90° coaxial bend allows to connect the boiler to a ue-air duct in any direction as it

can rotate by 360°. It can moreover be used as a supplementary bend and be coupled

with a coaxial duct or a 45° bend.

(*) The restrictor must be removed in case the ue duct length exceeds 1 m.

If the ue outlet is placed outside, the ue-air ducting must protrude at least 18mm out

of the wall to allow alluminium weathering tile to be tted and sealed to avoid water

leakages.

Ensure a minimum downward slope of 1 cm towards the outside per each metre of

duct length.

A 90° bend reduces the total duct length by 1 metre.

A 45° bend reduces the total duct length by 0.5 metre.

0609_0705 / CG_1792

0503_0904 / CG_1636

0503_0905 / CG_1638

Loading...

Loading...