GB

44

CN

GR

FR

SP

PT

Instructions pertaining to the installer

General information

Warning: When the selector switch

(1)

is set on Wintertime operation

( )

it may be

necessary to wait some minutes at each intervention of the central heating temperature

adjusting control

(5).

To relight the main burner immediately place the selector switch

(1)

on

(0)

and then again on

( ).

No waiting is needed when the boiler is in the DHW mode

on models with this option.

The following remarks and instructions are addressed to Service Engineers to help them

carry out a faultless installation. Instructions regarding lighting and operation of the boiler

are contained in the ‘Instructions pertaining to the user’ section.

Note that installation, maintenance and operation of the domestic gas appliances must be

performed exclusively by qualied personnel in compliance with current standards.

Please note the following:

*

This boiler can be connected to any type of double- or single feeding pipe convector

plates, radiators, thermoconvectors. Design the system sections as usual though

taking into account the available output / pump head performances, as shown on

page 50.

* Do not leave any packaging components (plastic bags, polystyrene, etc.) within

children’s reach as they are a potential source of danger.

*

Initial lighting of the boiler must be effected by a Qualied Service Engineer.

Failure to observe the above will render the guarantee null and void.

Instructions prior to installation

This boiler is designed to heat water at a lower than boiling temperature at atmospheric

pressure. The boiler must be connected to a central heating system and, on models

withis option, to a domestic hot water supply system in compliance with its performances

and output power.

Before connecting the boiler have the following operations effected:

a)

careful checking that the boiler is t for operation with the type of gas available. For

more details see the notice on the packaging and the label on the appliance itself.

b) careful checking that the ue terminal draft is appropriate; that the terminal is not

obstructed and that no other appliance exhaust gases are expelled through the same

ue duct, unless the ue is especially designed to collect the exhaust gase coming

from more than one appliance, in conformity with the laws and regulations in force

c)

careful checking that, in case the ue has been connected to pre-existing ue ducts,

thorough cleaning has been carried out in that residual combustion products may

come off during operation of the boiler and obstruct the ue duct.

To ensure correct operation of the appliance and avoid invalidating the guarantee, observe

the following precautions

1.

Hot water circuit

if the water hardness is greater than 20 °F (1 °F = 10 mg calcium carbonate per litre of

water) install a polyphosphate or comparable treatment system responding to current

regulations

2.

Heating circuit

2.1. new system

Before proceeding with installation of the boiler, the system must be cleaned

and ushed out thoroughly to eliminate residual thread-cutting swarf, solder and

solvents if any, using suitable proprietary products

2.2.

existing system:

Before proceeding with installation of the boiler, the system must be cleaned

and ushed out to remove sludge and contaminants, using suitable proprietary

products

To avoid damaging metal, plastic and rubber parts, use only neutral cleaners, i.e. non-

acid and non-alkaline (e.g. SENTINEL X400 and X100), proceeding strictly in accordance

with the maker’s directions

Remember that the presence of foreign matter in the heating system can adversely affect

the operation of the boiler (e.g. overheating and noisy operation of the heat exchanger)

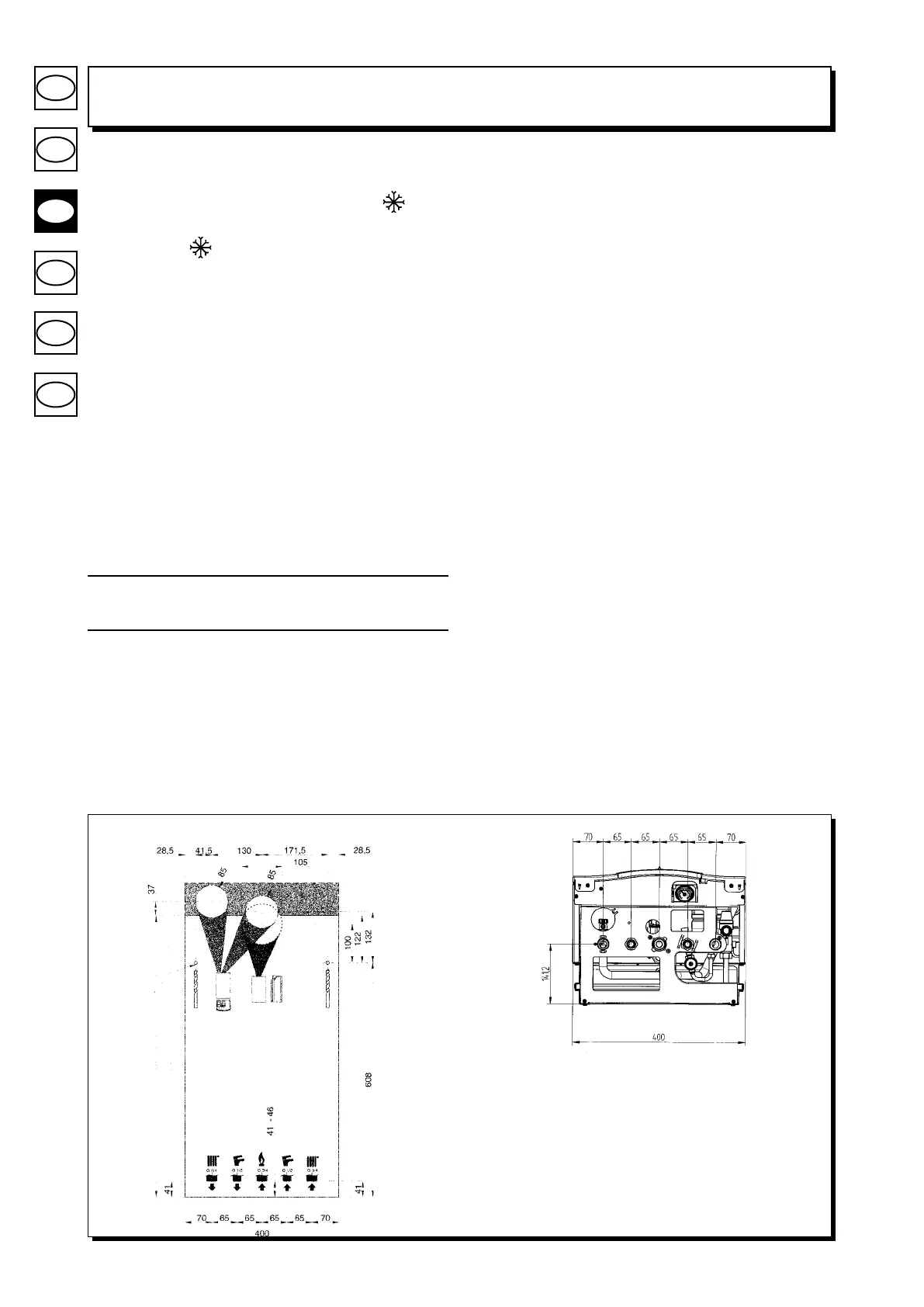

The template to fix the boiler on the wall

Decide upon the boiler location, then tape the template on the wall.

Connect the pipework to the gas and water inlets prearranged on the template lower

bar.

We suggest you t two G3/4 stop cocks (available on demand) on the central heating

system ow and return pipework; the cocks will allow to carry out important operations

on the system without draining it completely.

If you are either installing the boiler on a pre-existent system or substituting it, we

suggest you also t settling tanks on the system return pipework and under the boiler

to collect the deposits and scaling which may remain and be circulated in the system

after the purge.

When the boiler is xed on the template connect the ue and air ducts (ttings supplied

by the manufacturer) according to the instructions given in the following sections.

When installing the 2.24 CF model boiler with natural draught, make the connection to the

ue using a metal pipe which will provide resistance over time to the normal mechanical

stresses, heat and the effects of the combustion products and any condensation they

form.

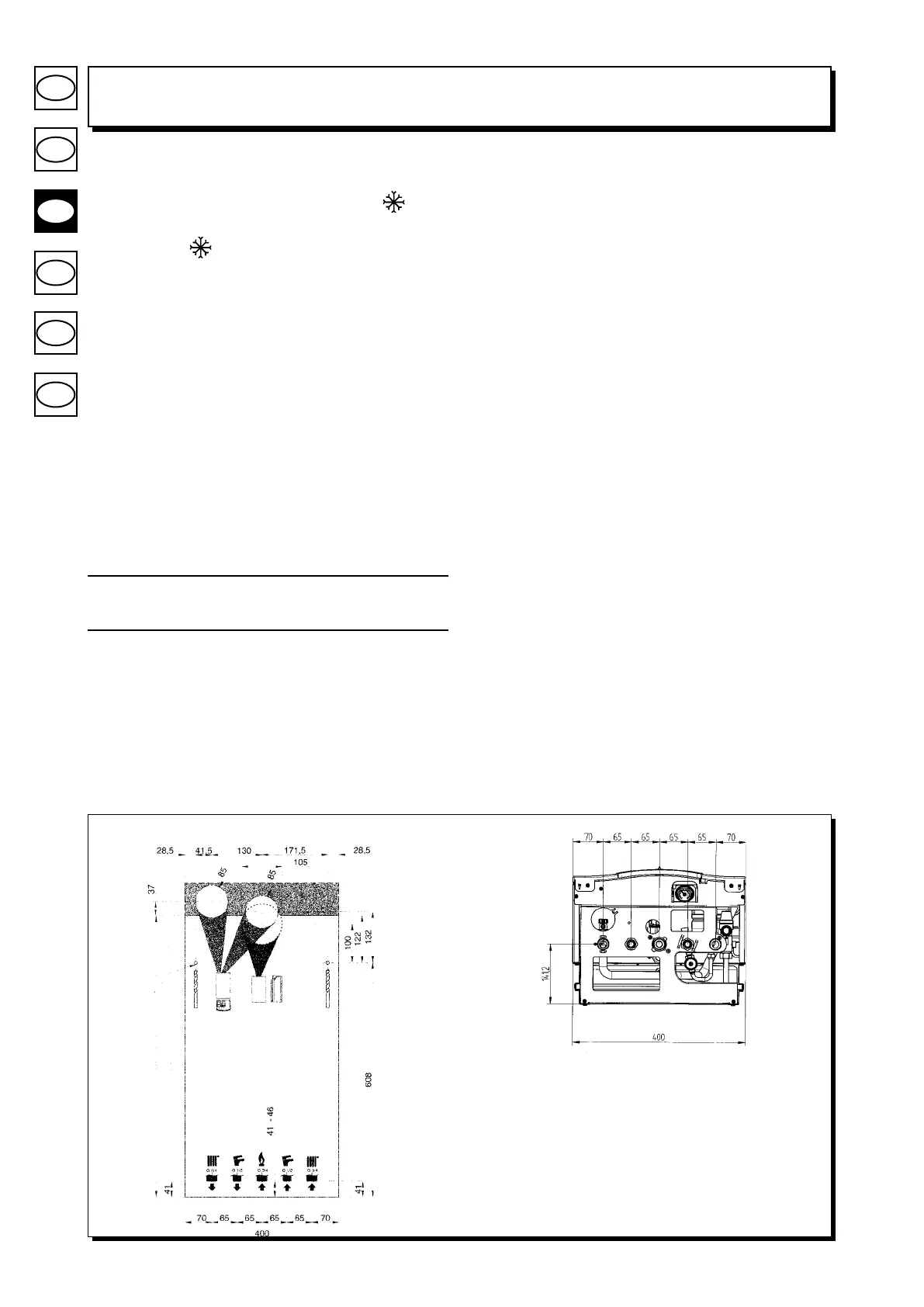

Figure 5

MR: G3/4 heating flow

US: G1/2 domestic hot water outlet

GAS: G3/4 gas inlet to the boiler

ES: G1/2 cold water inlet

RR: G3/4 heating return

0303_2808

0309_1101

BOILER CONNECTION POINTS

BOILER HEIGHT 730

Loading...

Loading...