30

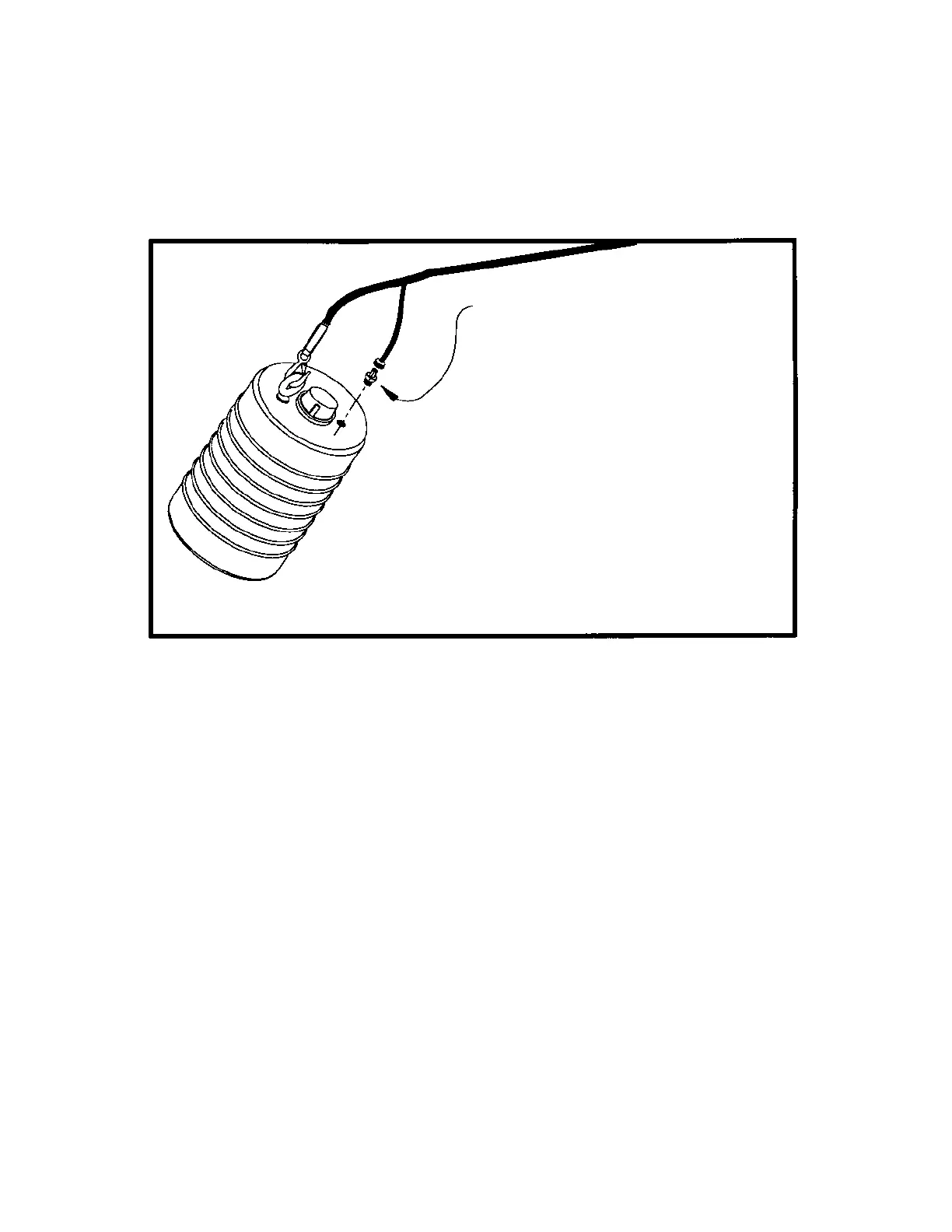

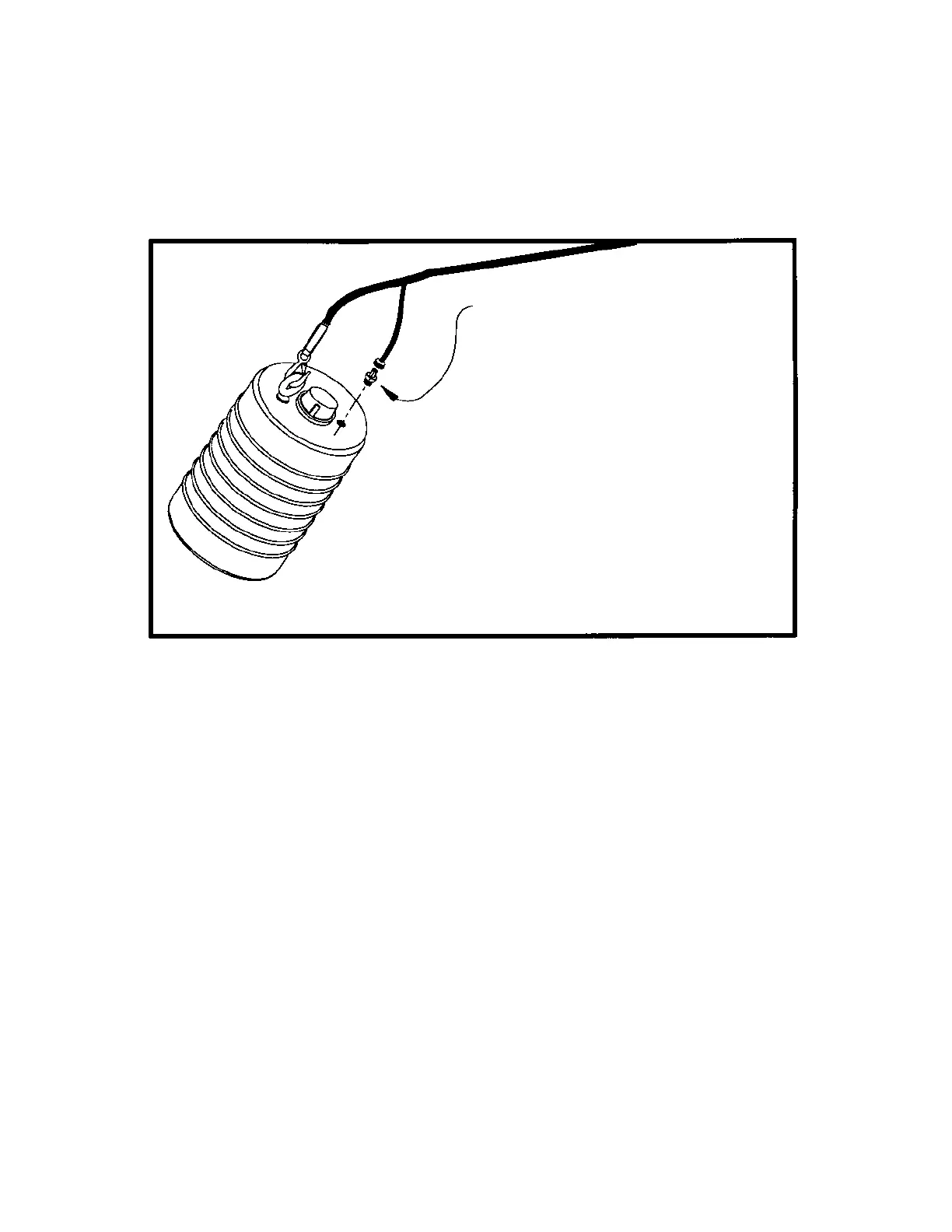

PLACEMENT OF PLUGS UNDER WATER. When installation requires a

plug to be submerged, remove the ination tting and partially ll the plug

with water to create neutral buoyancy. Properly replace the ination tting

(using pipe sealant or teon tape), correctly position the plug in the pipe

and then inate the plug normally with air through an ination extension

hose.

NEVER inate a pneumatic plug over or near a sharp object or obstruction.

Puncture of the plug body and failure may result upon plug ination and

use.

NEVER inate a pneumatic plug over lateral openings. The plug may

rupture upon ination in the non-supported body area. Note: Cherne

Long Test-Balls® and MS2® Long Test-Balls® are designed for use in

wye pipeline sections where the plug body is not completely supported.

Clean-Seal® plugs are designed for use in blocking test tees that have an

unsupported area on each branch of the tee.

NEVER allow a pneumatic plug to protrude from the end of a pipeline

during ination or use. The plug may rupture upon ination or dislodge

when back pressure is applied.

NEVER inate a pneumatic plug outside of a pipeline in excess of one (1)

PSIG. The plug may rupture catastrophically.

THE INFLATOR

CAN BE REMOVED

TEMPORARILY TO

FILL PLUG WITH

WATER TO PROVIDE

NEUTRAL BUOYANCY.

USE PIPE SEALANT

OR TEFLON TAPE

WHEN REPLACING

INFLATOR FITTING.

PLACEMENT OF PLUGS UNDER WATER

Loading...

Loading...