E1

SAFETY PRECAUTIONS

INST.No.KP3-41-3

Digital Program Controller / Setter

KP1000 / KP2000 / KP3000

Instruction Manual

for Installation

Thank you for purchasing the KP1000 / KP2000 / KP3000.

Before operating the product described in this user’s manual, please

take note of the following points regarding safety.

Be sure to keep this manual nearby for handy reference.

Please read the "Terms and Conditions" from the following URL

before ordering or use:

https://www.chino.co.jp/support/guarantee/index.html

NOTICE

Be sure that the user receives this manual before the product is

used. Copying or duplicating the manual in part or in whole is

forbidden. The information and specifications in the manual are

subject to change without notice. Considerable effort has been

made to ensure that this manual is free from inaccuracies and

omissions. If you should find an error or omission, please contact

your nearest CHINO office. In no event is CHINO liable to anyone

for any indirect, special or consequential damages as a result of

using this product.

This manual only explains the handling precautions, mounting,

wiring, input type, list of parameters and main specifications.

For instruction manual other than this document, go to CHINO

homepage https://www.chino.co.jp, register for a membership, and

download. See KP1000, KP2000 or KP3000 Instruction manual

(General) for the detail handling procedures etc.

Unpacking

Check the following items when removing the KP1000, KP2000, and

KP3000 from its package:

Name Q'ty Remarks

Mounting Bracket 2 (1 set) For panel mounting

Instruction Manual

(installation)

1 This Manual

Contact protection

element

1

ttached to ON-OFF servo type

specifications only

A protective film is attached to the front console of this unit to protect

the surface. After installation and wiring are complete, peel off the film

before use.

The use of this product in a manner not specified by the manufacturer

will impair its built-in safety features.

WARNING

PRECAUTION

Quick Start Guide

From installation to Input type and Program pattern setup

Step 1. Mount..................................Page E3

Step 2. Wire………………………….Page E4

Step 3. Set Input type……………..Page E13

Step 4. Set the Program pattern...Page E13

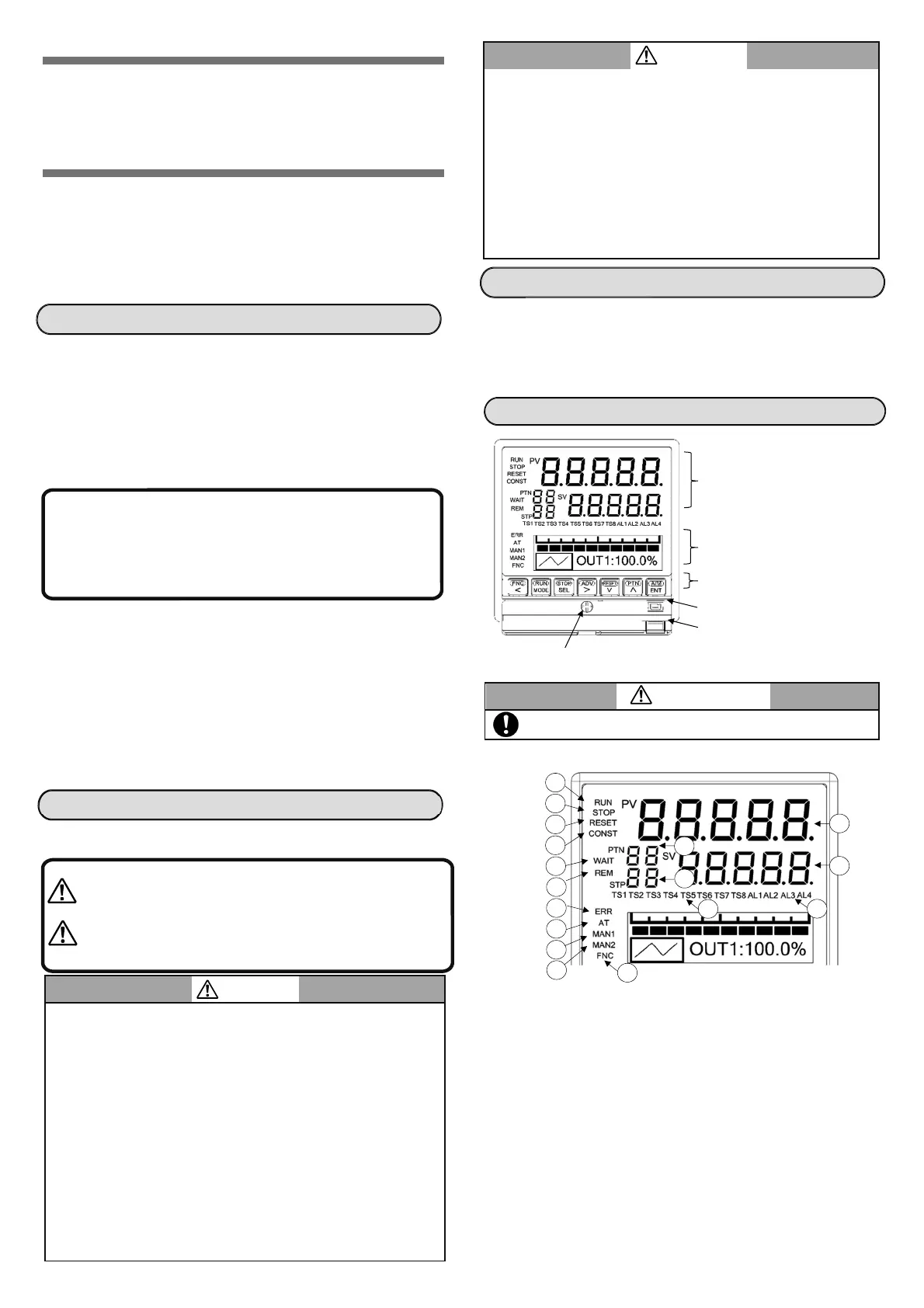

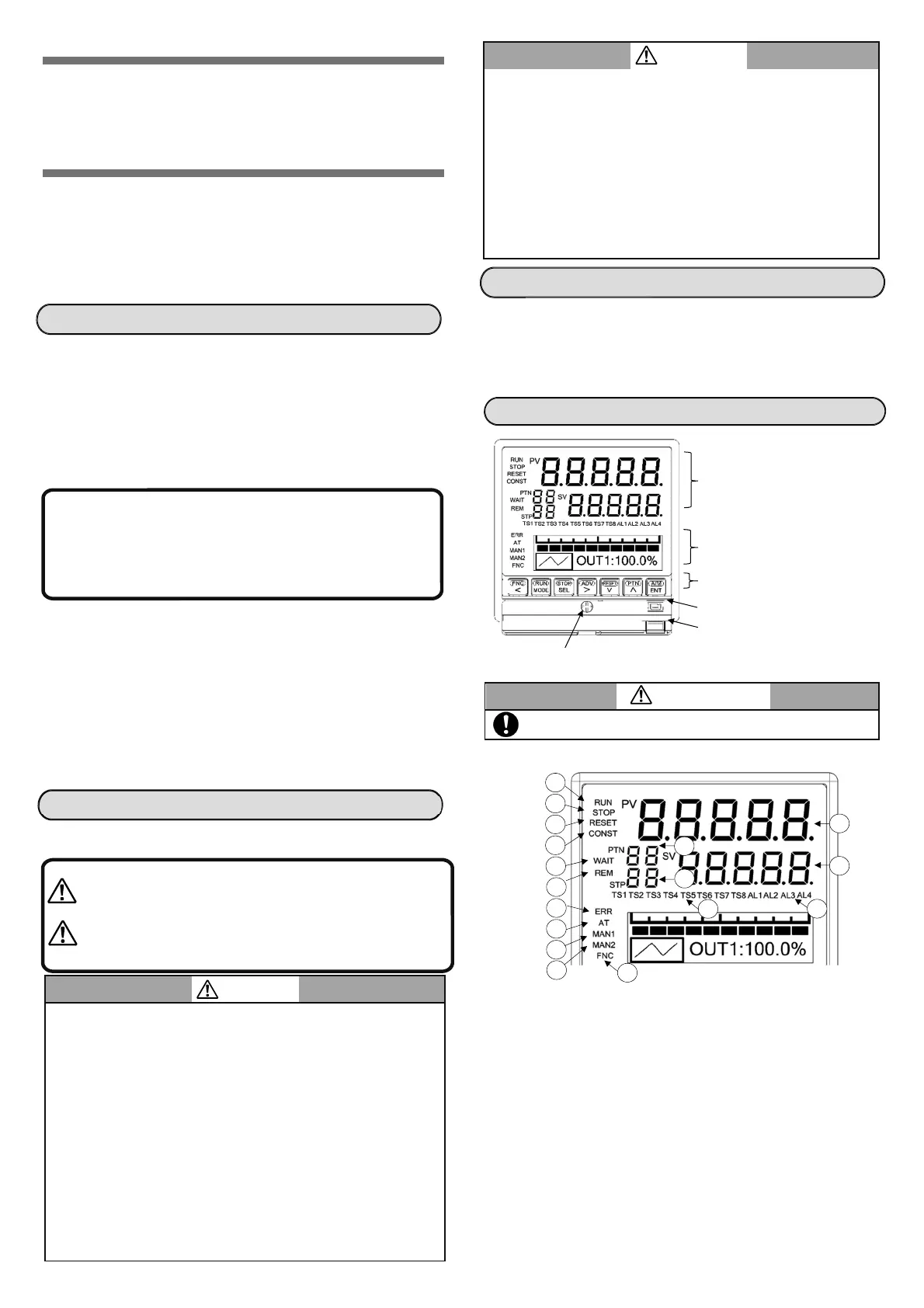

Part names and functions

Upper display

(1) PV (KP1000/KP2000)

Displays PV (measurement value).

(2) SV

Displays SV (setting value).

(3) PTN No.

Displays the pattern number that is being selected.

Blinks when PTN is changed.

(4) STP No.

Displays the step number that is being executed.

During real temperature compensation operation, the

numeral of the No. blinks.

(5) RUN

Lights during RUN status.

Blinks during FAST status.

WARNING

(1)Before supplying the power to the product, check that the wiring is

correct and power supply voltage matches with the rated voltage

etc.

(2)This product does not have a power supply switch. Install a circuit

breaker that matches the rating specifications in the power supply

of the product.

(3)To prevent electric shock, provide the terminal of the product with

safety measures such that the user will not be able to touch the

final product directly.

(4)

This product is designed as a general-purpose product for general

industrial products. It is not intended for use in human-life and

property related applications such as nuclear and radiation related

equipment, medical equipment, aerospace equipment, railroad, and

marine transportation equipment. To use this product for equipment

that requires high quality and safety that affects human-life and

property, design and install the protection and safety circuits to

ensure safety at your own responsibility.

(5)Do not put your hand and tool inside the product. You may get an

injury or an electric shock.

WARNING

(6)If there is offensive smell, strange noise or smoke or if the

temperature increases abnormally, it is very risky hence cut off the

power supply immediately and contact the dealer or nearest

CHINO's office.

(7)If repairing or remodeling is necessary, contact the dealer or

nearest CHINO's office. Only the service engineers appointed by

our company will change the parts, do the repairing and

remodeling.

(8)In order to use the product correctly and safely, follow this

instruction manual. Please understand beforehand that our

company will not at all be responsible for any claims for injury,

damage, and passive damage due to wrong use of the product.

PRECAUTION

This internal rack fixing screw is used at the time of

maintenance.

Warnings are indicated when there is a risk of

operator death or serious injury. Information is

provided regarding how to avoid this risk.

Cautions are indicated when there is a risk of

operator injury, damage to the product, and/or

damage to peripherals. Information is provided

regarding how to avoid this risk.

Upper display

Lower display

Key switch panel

Engineering port

Lower cover

Internal rack fixing screw

5

3

1

2

6

7

8

9

10

11

12

13

16

4

14

17

15

Loading...

Loading...