The 42LE (Fig. 1) is a four-speed transaxle that is

a conventional hydraulic/mechanical assembly with

an integral differential, and is controlled with adap-

tive electronic controls and monitors. The hydraulic

system of the transaxle consists of the transaxle

fluid, fluid passages, hydraulic valves, and various

line pressure control components. An input clutch

assembly which houses the underdrive, overdrive,

and reverse clutches is used. It also utilizes separate

holding clutches: 2nd/4th gear and Low/Reverse. The

primary mechanical components of the transaxle con-

sist of the following:

• Three multiple disc input clutches

• Two multiple disc holding clutches

• Four hydraulic accumulators

• Two planetary gear sets

• Hydraulic oil pump

• Valve body

• Solenoid/Pressure switch assembly

• Integral differential assembly

Control of the transaxle is accomplished by fully

adaptive electronics. Optimum shift scheduling is

accomplished through continuous real-time sensor

feedback information provided to the Transmission

Control Module (TCM).

The TCM is the heart of the electronic control sys-

tem and relies on information from various direct

and indirect inputs (sensors, switches, etc.) to deter-

mine driver demand and vehicle operating condi-

tions. With this information, the TCM can calculate

and perform timely and quality shifts through vari-

ous output or control devices (solenoid pack, trans-

mission control relay, etc.).

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC’s, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

TRANSAXLE IDENTIFICATION

The 42LE transaxle identification code is a series

of digits printed on a bar-code label that is fixed to

the transaxle case as shown in (Fig. 2).

For example, the identification code K 821 1125

1316 can be broken down as follows:

• K = Kokomo Transmission Plant

• 821 = Last three digits of the transaxle part

number

• 1125 = Build date

• 1316 = Build sequence number

If the tag is not legible or missing, the “PK” num-

ber, which is stamped into the transaxle case, can be

referred to for identification. This number differs

slightly in that it contains the entire transaxle part

number, rather than the last three digits.

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

First .............................. 2.84 : 1

Second ............................. 1.57 : 1

Third .............................. 1.00 : 1

Overdrive .......................... 0.69 : 1

Reverse ............................ 2.21 : 1

1 – DIFFERENTIAL

2 – TRANSFER SHAFT

3 – TRANSFER GEAR

4 – FRONT PLANETARY CARRIER

5 – REAR PLANETARY CARRIER

6 – OUTPUT SHAFT

7 – OUTPUT GEAR

8 – OUTPUT SPEED SENSOR

9 – LOW/REVERSE CLUTCH

10 – 2/4 CLUTCH

11 – REVERSE CLUTCH

12 – OVERDRIVE CLUTCH

13 – UNDERDRIVE CLUTCH

14 – INPUT SPEED SENSOR

15 – CONVERTER CLUTCH

16 – OIL PUMP

17 – INPUT SHAFT

18 – TORQUE CONVERTER

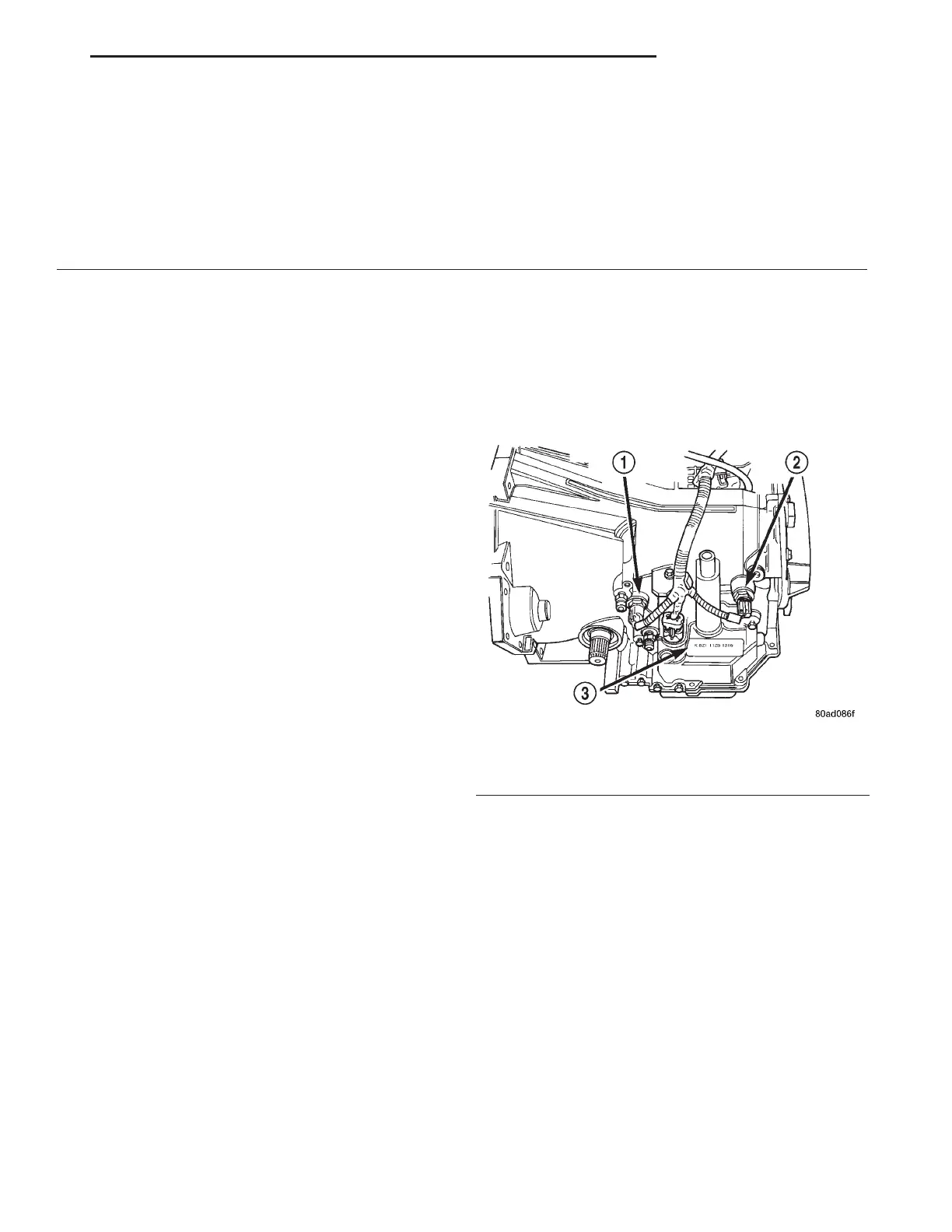

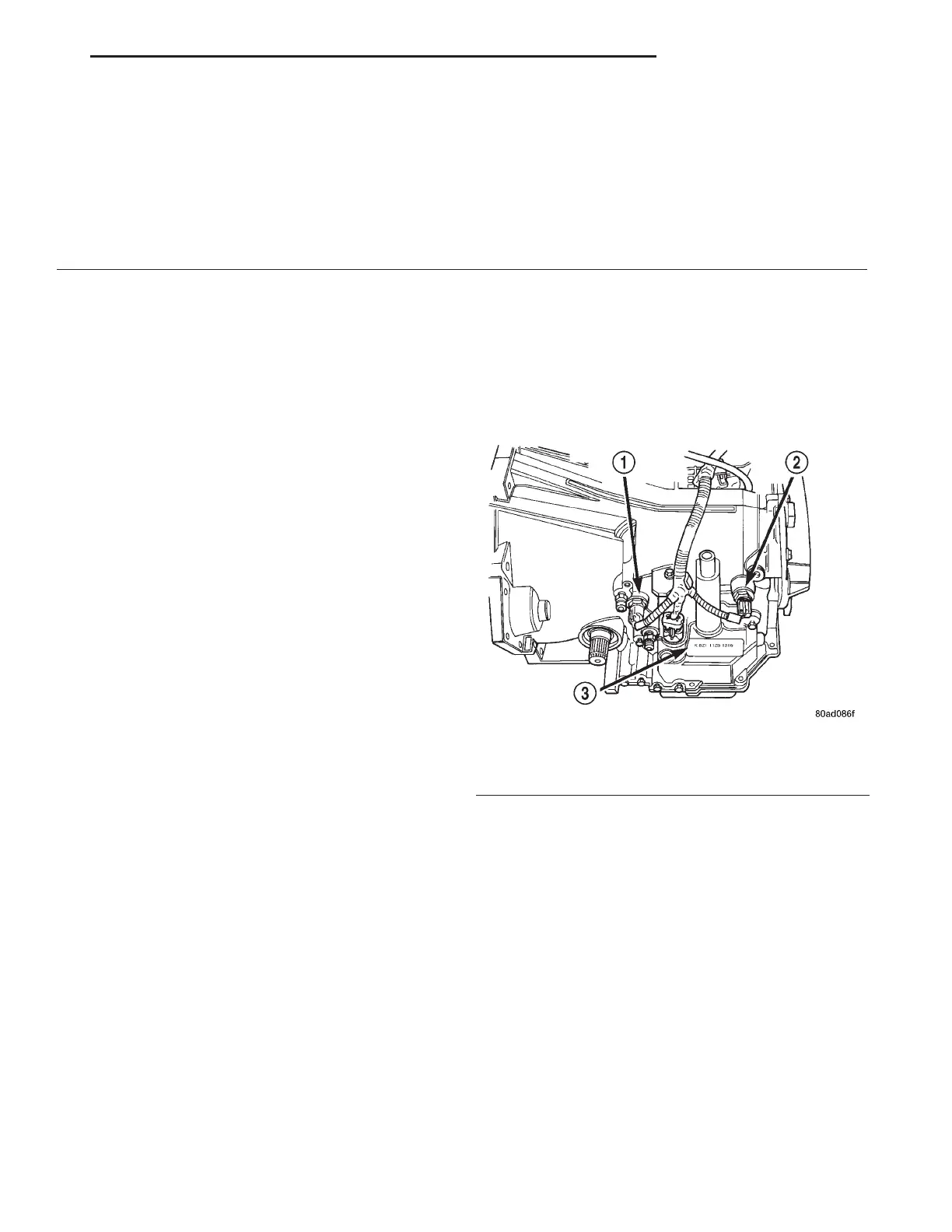

Fig. 2 Transaxle Identification Label

1 – INPUT SPEED SENSOR

2 – OUTPUT SPEED SENSOR

3 – IDENTIFICATION TAG

LH 42LE TRANSAXLE 21 - 3

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...