REMOVAL

(1) Loosen tensioner pulley locking nut.

(2) Raise vehicle on hoist.

(3) Remove the two (2) push clips attaching lower

air shield to engine cradle. Remove air shield.

(4) Loosen tensioner adjusting bolt until the belt

can be removed.

INSTALLATION

(1) Install generator/power steering belt.

NOTE: Use Special Tool 7198, Belt Tension Gauge

to obtain proper tension on accessory drive belt.

Refer to Belt Tension Chart.

(2) Tighten adjusting bolt until the specified ten-

sion is obtained.

(3) Install lower air shield and attaching push

clips.

(4) Lower vehicle.

(5) Tighten tensioner pulley locking nut.

Generator/Power Steering Belt Tension Adjustment

Loosen the tensioner pulley locking nut and adjust

belt tension by tightening adjusting bolt. Use Belt

Tension Gauge and refer to Belt Tension Chart for

specifications. Torque pulley nut to 54 N·m (40 ft.

lbs.) after adjustment.

CLEANING AND INSPECTION

WATER PUMP

CLEANING

Clean all gasket mating surfaces as necessary.

INSPECTION

Inspect and replace the water pump if it has any of

the following defects:

(1) Damage or cracks on the pump body.

(2) Coolant leaks; if the seal is leaking, this will be

evident by traces of thick deposits of dried glycol run-

ning down the pump body (3.2/3.5L), pump weep pas-

sage (2.7L) (Fig. 47), and components below. A thin

black stain below pump weep hole/passage is consid-

ered normal operation.

(3) Impeller rubs inside of cylinder block (2.7L) or

timing belt cover (3.2/3.5L) engines.

(4) Excessively loose or rough turning bearing.

NOTE: It is normal for the water pump to weep a

small amount of coolant from the weep hole (black

stain on water pump body). Do not replace the

water pump if this condition exists. Replace the

water pump if a heavy deposit or a steady flow of

engine coolant is evident on water pump body (3.2/

3.5L) or from the weep passage (2.7L) (Fig. 47). This

indicates a shaft seal failure and pump must be

replaced. Be sure to perform a thorough analysis

before replacing water pump.

ACCESSORY DRIVE BELTS

CLEANING

Clean all foreign debris from belt pulley grooves.

The belt pulleys must be free of oil, grease, and cool-

ants before installing the drive belt.

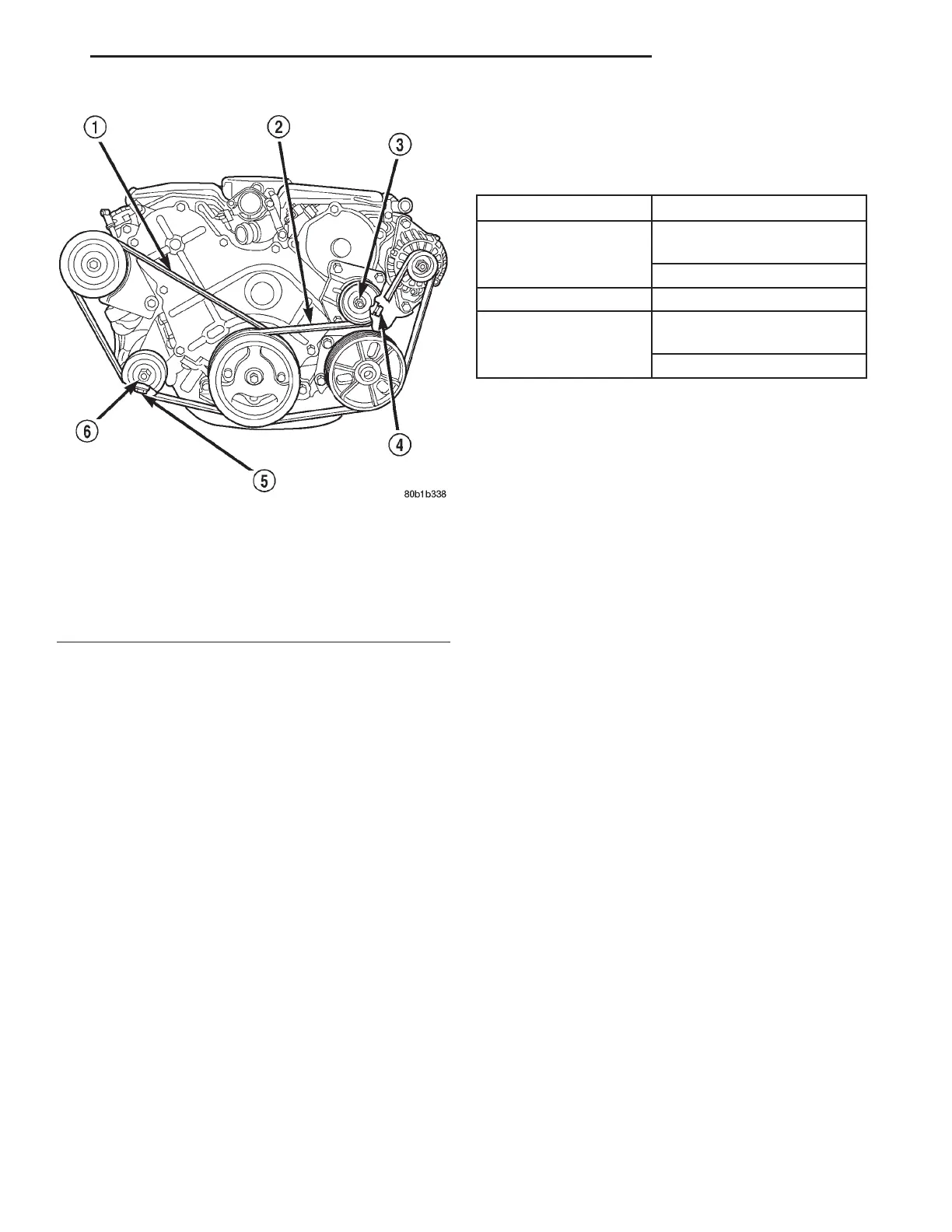

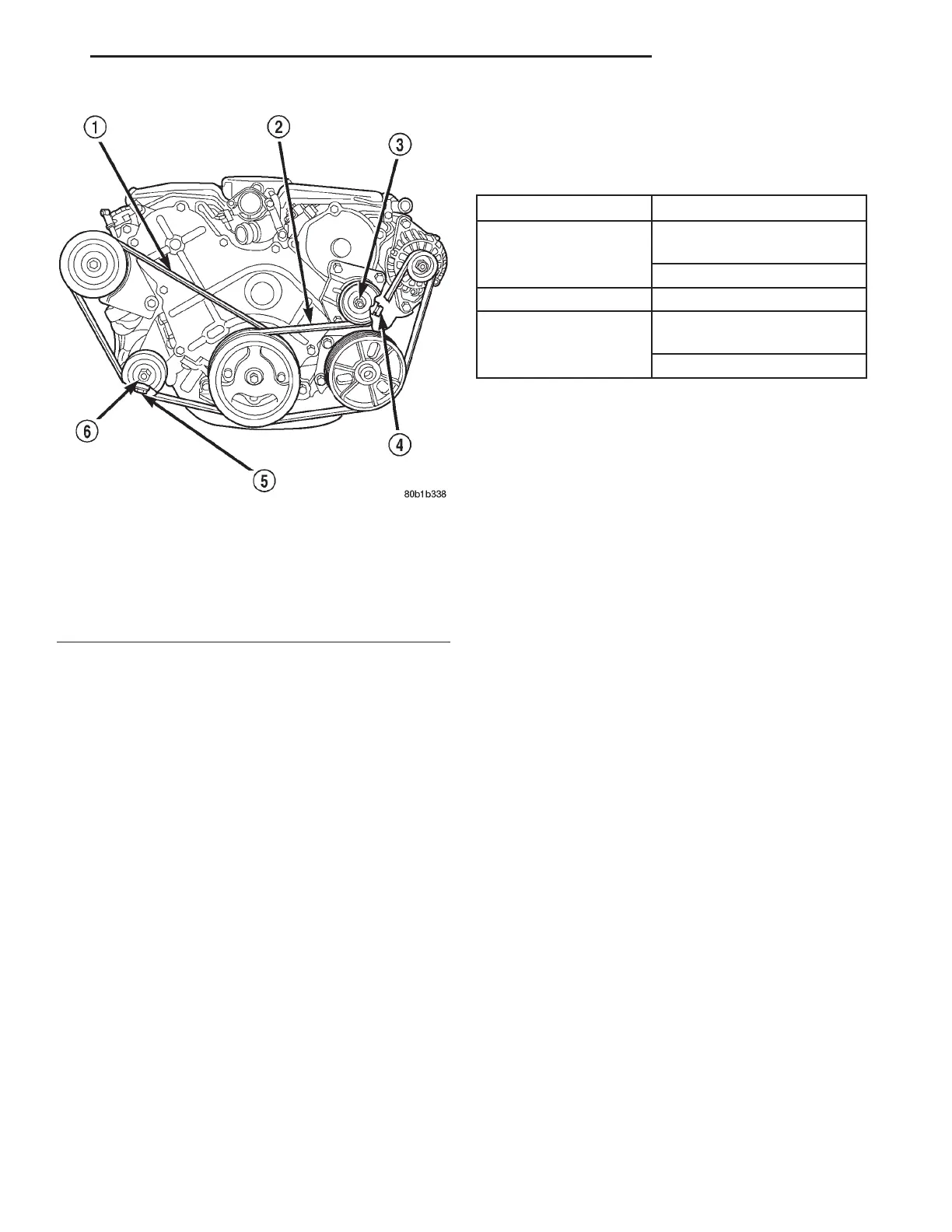

Fig. 46 Accessory Drive Belts

1 – V-BELT

2 – POLY-V BELT

3 – LOCKING NUT

4 – ADJUSTING BOLT

5 – ADJUSTING BOLT

6 – LOCKING NUT

BELT TENSION CHART—3.2/3.5L

POLY-V BELT GAUGE

Generator/Power

Steering Belt

New Belt: 836 644 N

(190 610 lbs.)

Used Belt: 534 N (120 lbs.)

V-BELT GAUGE

Air Conditioning Belt New Belt: 667 644 N

(150 610 lbs.)

Used Belt: 534 N (120 lbs.)

LH COOLING SYSTEM 7 - 35

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...