refills the high pressure chamber with non-aerated

oil.

(e) Remove probes to allow check balls to seat.

(f) Recheck for sponginess. If the lash adjuster

sponginess is not completely or nearly eliminated,

then repeat procedure.

(g) If the spongy condition cannot be removed,

replace effected rocker arm(s).

(6) Install cylinder head cover(s).

PISTONS

Pistons are machined to two different weight spec-

ifications and matched to rods based on weight. All

piston and rod assemblies weigh the same to main-

tain engine balance.

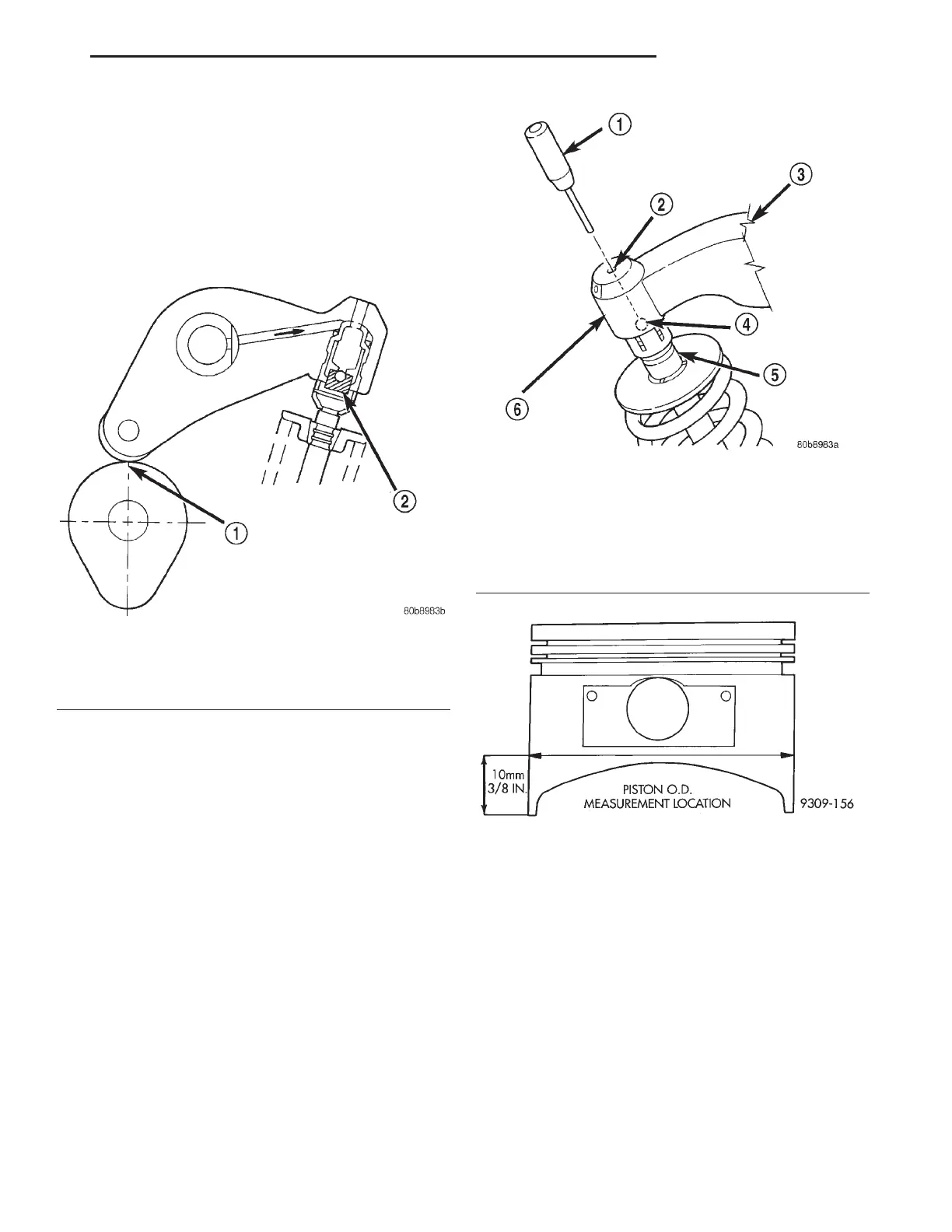

FITTING PISTONS

Piston and cylinder wall must be clean and dry.

Piston diameter should be measured 90 degrees to

piston pin at size location shown in (Fig. 21). Cylin-

der bores should be measured halfway down the cyl-

inder bore and transverse to the engine crankshaft

center line. Refer to Engine Specifications. Pistons

and cylinder bores should be measured at nor-

mal room temperature, 70°F (21°C).

PISTON PINS

The piston pin is full floating and is held in place

by lock rings. Pistons and rods are weight matched

for balance. Do Not switch pistons with other

rods. Piston and Rods are serviced as an assembly

for balance.

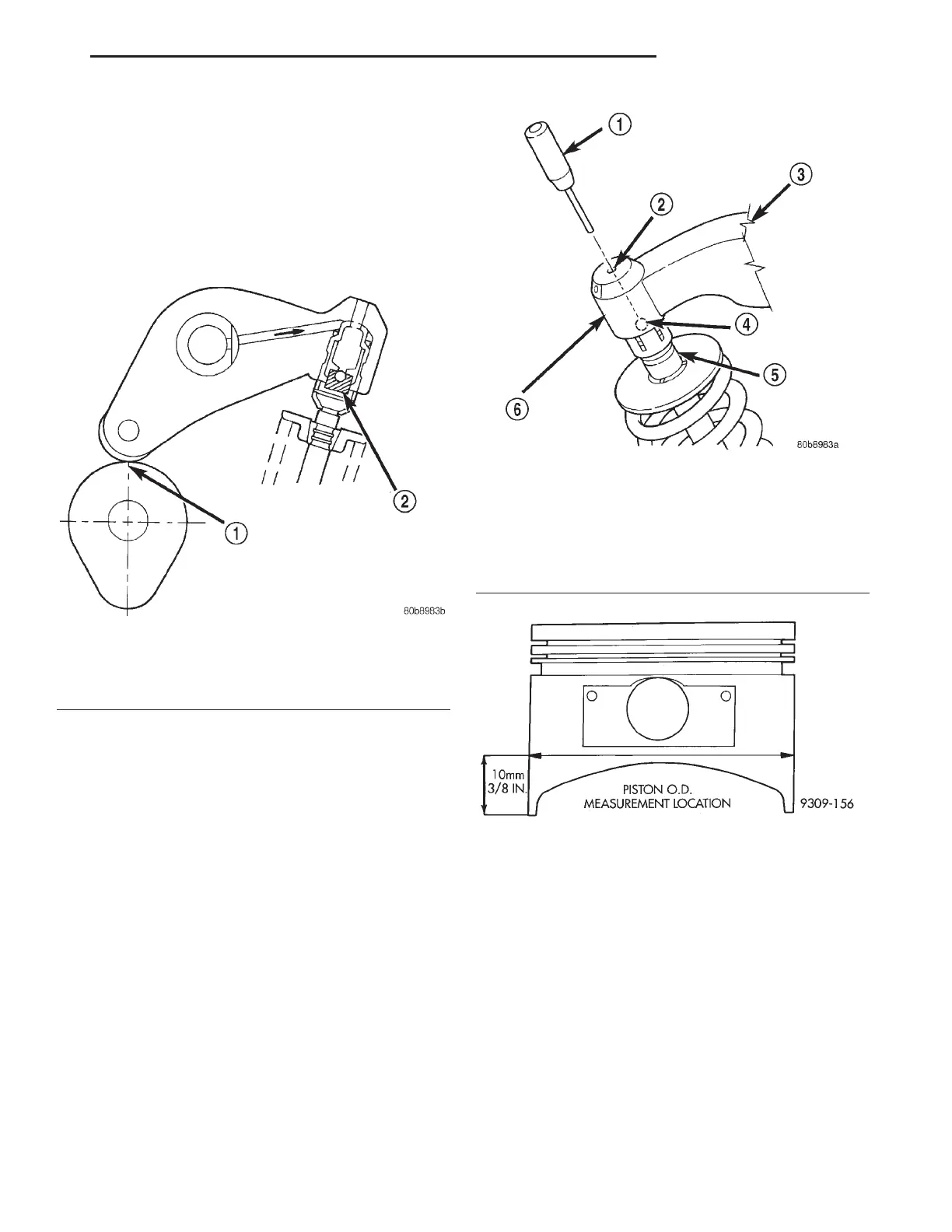

Fig. 19 Rocker Arm Positioned On Base Circle Of

Camshaft

1 – CAMSHAFT BASE CIRCLE

2 – HIGH-PRESSURE CHAMBER

Fig. 20 Purging Air From Lash Adjuster

1 – SPECIAL TOOL 8351

2 – OIL AIR RELIEF SERVICE ACCESS HOLE

3 – ROCKER ARM ASSY

4 – INTERNAL CHECK BALL

5 – VALVE TIP

6 – HYDRAULIC LASH ADJUSTER WITHIN ROCKER ARM

Fig. 21 Piston Measurements

LH 3.2/3.5L ENGINE 9 - 95

SERVICE PROCEDURES (Continued)

Loading...

Loading...