09-2008

Plus 42 - 45 - 50 - 55

25

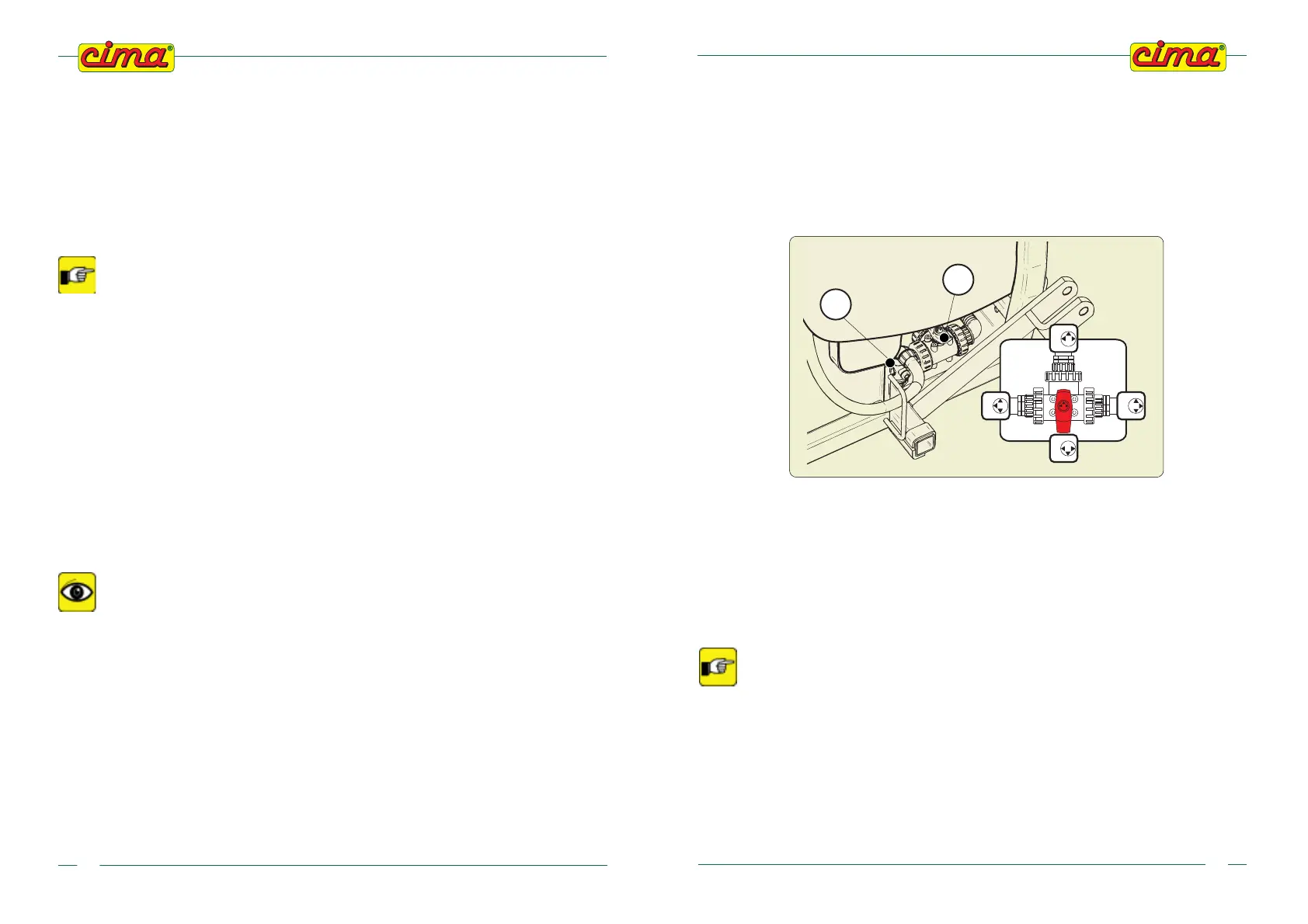

P15 - 3-WAY PLANT-WASHING TAP (For the models on which it is foreseen)

The cock (P15) is joined to the tank (P1) and, on one side, to the plant-washing tank (P17) through pipe

(T7), on the other side it is joined to the centrifugal pump (P4) through the suction pipe (T1).

The unit-washing circuit allows to wash the hydraulic circuit (with the exclusion of the tank), in every

moment and independently on the tank load conditions, i.e., also with the mixture present inside the

tank. When the tap (P15) is placed to position “b”the clean water for the unit washing is taken from

the unit-washing tank (P17) by simultaneously excluding the suction from the main tank.

The 3-way cock lever can be positioned as here following specified:

a – TREATMENT (WORK)

The liquid gets out from the tank (P1) and is sucked by the pump (P4); this is the NORMAL operating

position, which is used in order to carry out the treatment and/or to keep the mixing on. The connection

with washing tank is closed.

b – WASHING PROCESS

The fluid gets out from the unit-washing tank (P17) and is sucked by the pump (P4); that is the position

which is used, in order to carry out the hydraulic circuit WASHING.

TO AVOID THE RETURN OF CLEAN WATER TO THE TANK, WITH CONSEQUENT DILUTION

OF THE MIXTURE CONTAINED IN IT, CLOSE THE FAUCET (P3) AND COMPLETELY CLOSE

THE REGULATOR by rotating the manual regulator handle (P5) clockwise or by

turning the pressure up (keep the joystick on “+” for about 15 seconds for the

versions with pressure regulation electrovalve), DURING THE WASHING.

c – EMPTYING OF THE TANK

In this position, the tank (P1) is emptied. The union with the centrifugal pump is closed. In order

to empty the tank, the drain plug of the union tee (P16) must be removed.

d – COMPLETE DRAINAGE

In this position, it is possible to empty: the tank (P1), the pump (P4) and all the pipes of the hydraulic

circuit. If the plant-washing tank is also filled, it is emptied too.

P16

P15

d

b

a

c

00680

00680

Plus 42 - 45 - 50 - 55

09-2008

44

g. Keep to the preliminary operations already indicated (10.1.c), in case of wind conditions prevailing.

h. Stop the engine, remove the key from the tractor’s control panel and lower the hoist during

stoppages.

i. Pay particular attention to the treatment when close to boundaries and in proximity of dwellings,

waterways, roads or public-usage paths.

10.4 - PROCEDURE TO WASH THE HYDRAULIC CIRCUIT

(head-pump)

In case of machines equipped with unit-washing tank, every time it is necessary

to suspend the treatment, it is possible to carry out the hydraulic circuit washing

process, independently on the loading conditions, i.e., also when the tank is still

containing some product mixture, so avoiding any possible clogging and assuring

the perfect efficiency of the machine when the treatment is carried on again.

In case of prolonged idle periods, it is recommended to keep the mixture agitated

(see Chapter 9).

In order to carry out the hydraulic circuit washing process, follow the instructions here specified:

a. Close the faucet (P3) of exclusion of the additional agitation.

b. Close the pressure regulator completely, by rotating the hand regulator (P5) handle clockwise or

by turning the pressure up (keep the joystick on “+” for about 15 seconds) for the E.P.A. versions.

c. Open the cock (P15), by setting it to position “b”; in that way the clean water contained inside the

unit-washing tank is sucked by the pump (P4) and gets into the hydraulic circuit.

d. Engage the PTO and take it to the correct distribution condition (540 rev/min - see paragraph 4.4.2)

CAUTION: THE PUMP MUST NEVER RUN DRY

e. Aprire i rubinetti del distributore manuale (P9) (o le elettrovalvole E9 portando su ON gli interruttori

sulla centralina elettrica di comando E10); far funzionare l’atomizzatore, irrorando sull’appezza-

mento ancora da trattare, per un tempo sufficiente a verificare la fuoriuscita di acqua pulita dalla

testata di distribuzione.

That easy procedure allows to eliminate every fuel mixture residual from all the

hydraulic circuit components, so assuring in first place the accurate cleaning and the

consequent efficiency of the calibrated holes of the rotary disc regulators.

f. Disengage the PTO.

g. Close the cock (P15) by taking it to the A-WORK position

h. Open the faucet (P3) of exclusion of the additional agitation.

Loading...

Loading...