Plus 42 - 45 - 50 - 55

09-2008

34

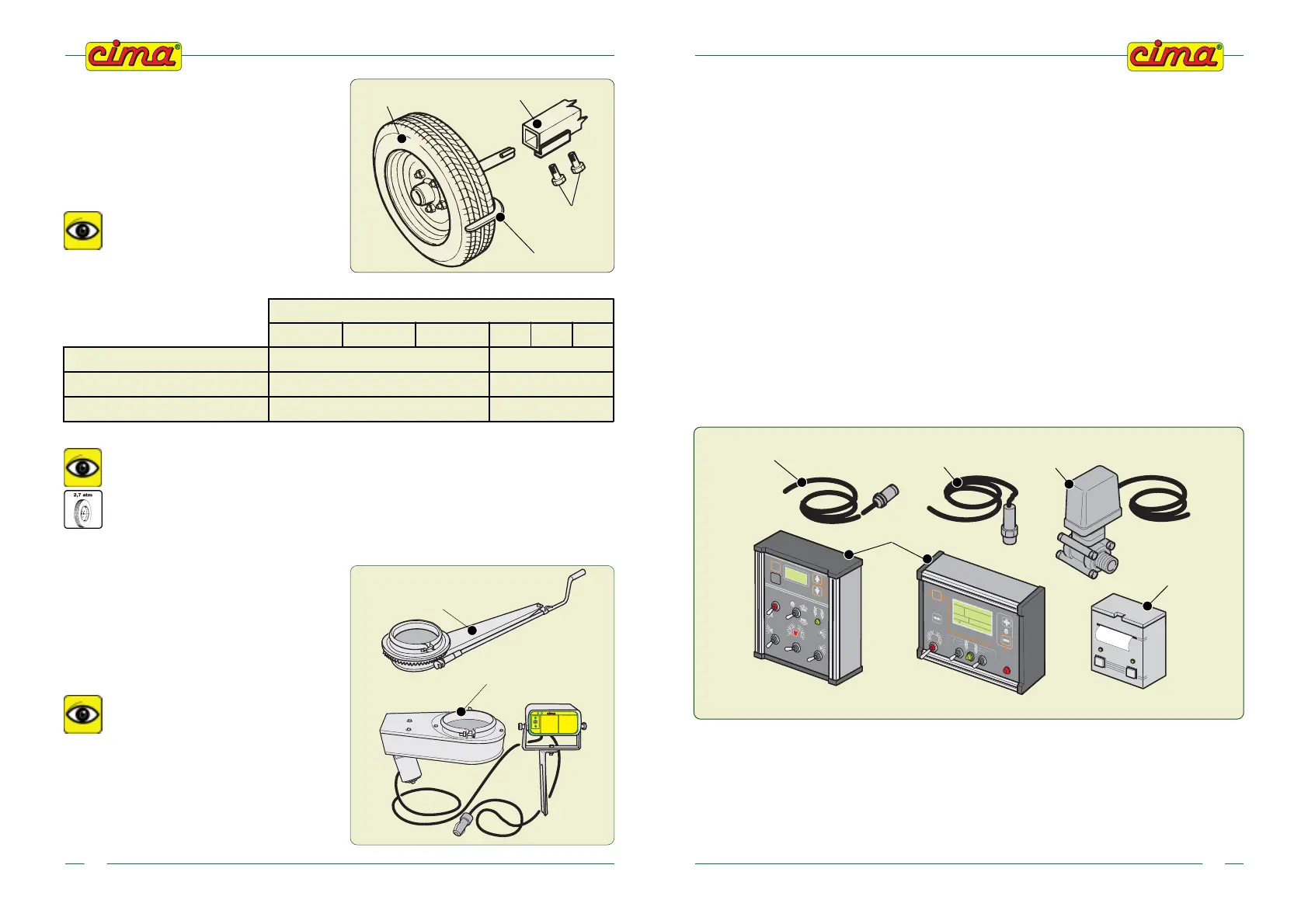

3. Insert the wheels’ axle shafts into the ma-

chine’s axle.

4. Adapt the wheels’ track to that of the tractor.

5. Lock the axle shafts by means of the axle

screws.

6. Start the tractor and keep the sprayer lifted

during the transfers, lowering it to carry out

the treatment.

THE SPRAYER MUST BE LIFTED AT

EVERY DIRECTION CHANGE MAKING

SURE THAT THE WHEELS ARE NOT

RESTING ON THE GROUND.

The utilisation of NON ORIGINAL pairs of wheels not equipped with mud scrapers

will nullify the machine’s warranty.

The operating pressure of the tyres is indicated on the decal placed on the rim of

each wheel.

Type of mounted sprayer PLUS

42 45 50 55 55S 55E

Wheel dimension

135/80 - R13 -70T 175/70-R13-82T

Wheel pressure (atm)

2,7 2,7

Wheel weight, with axles (kg)

40 44

UMAPT07

00029

WHEEL WITH

AXLE SHAFT

LOCKING

SCREWS

FRAME

MUD SCRAPER

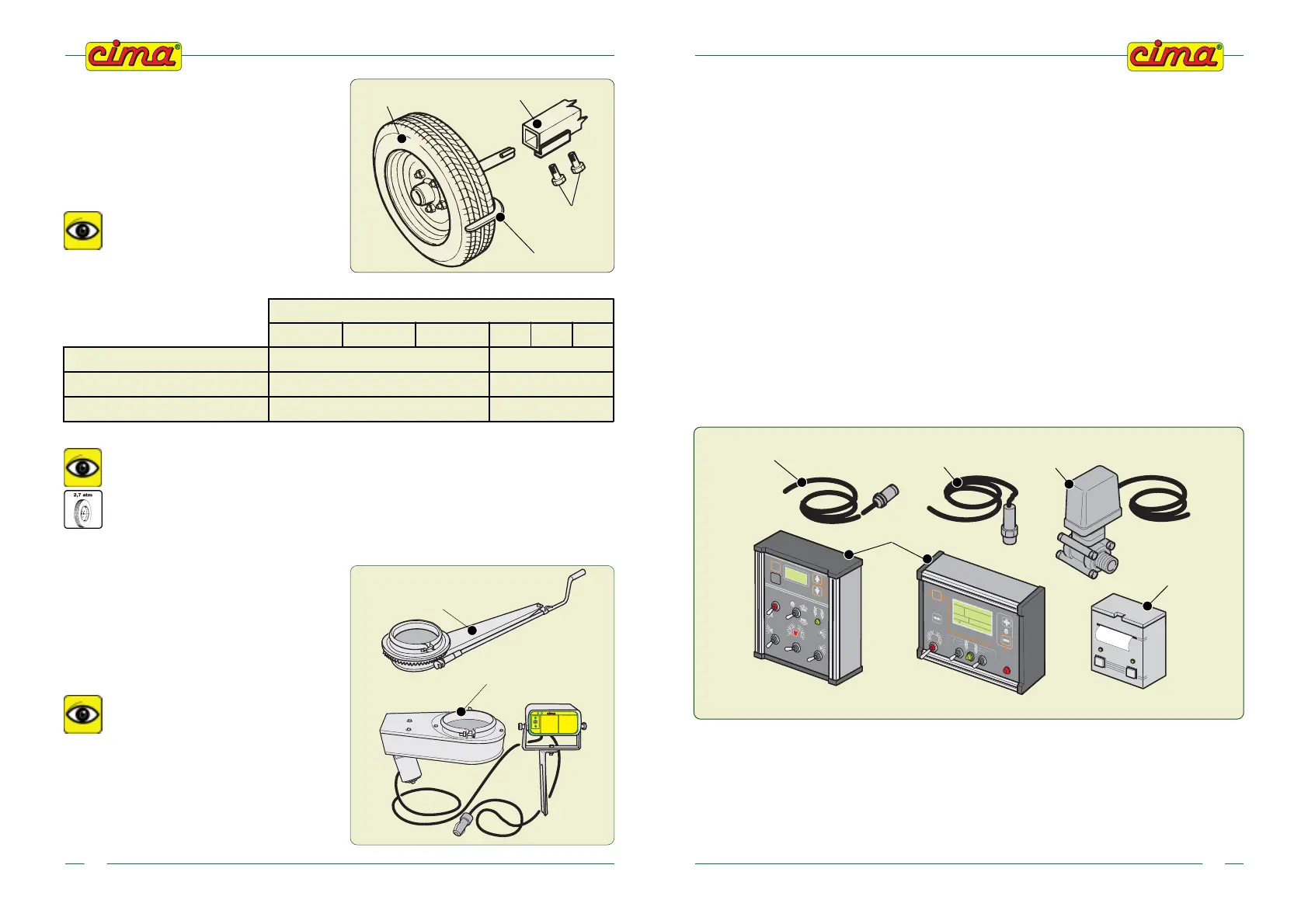

7.3 - SWIVELLING DEVICE

It is an accessory used to modify the direction of

the spraying during the use of the sprayer; it can

be used only with the distribution devices with

delivery on the one side.

There is two type of swivelling device: manual

controlled or electrical with remote control panel.

All indications and instructions are

provided in the “Distribution heads

- Operation and maintenance in-

struction” booklet of the distribu-

tion devices with which it can be

used.

®

Remote Control

00616

00617

MANUAL

SWIVELLING

DEVICE

ELECTRICAL

SWIVELLING DEVICE

WITH CONTROL PANEL

09-2008

Plus 42 - 45 - 50 - 55

35

7.4 - E.P.A. Kit - DELIVERY PROPORTIONAL ADVANCEMENT

(for the version where foreseen)

The computerized E.P.A. system executes the monitoring of the distribution parameters for the active

automatic control of the distribution proportional to the feed.

Through the constant takeover of the feed speed and the range of the product it is able to regulate

the pressure continuously to keep the quantity of distributed product constant in relation to the treated

surface.

The Kit is available in two versions:

- Version “Teejet

®

76AB”;

- Version “Teejet

®

844AB.”

Both versions are constituted from:

1. Magnetic induction proximity sensor (speed survey);

2. Pressure transducer (pressure survey);

3. Motorized electric valve (pressure regulation);

4. Computerized unit;

5. Dedicated printer (“Teejet® 844AB” version only).

For further information refer to the specific handbook.

m

.

A

U

T

M

A

N

O

N

P

R

O

C

L

R

O

N

O

F

F

0

L

H

A

C

O

N

FIG

2

m

.

A

U

T

O

P

R

O

O

N

O

F

F

1

2

3

1

2

3

P

r

o

D

M

A

N

2

x

P

O

F

F

O

N

3

2

1

1

2

3

G

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

H

a

K

m

/

H

B

a

r

L

/

H

a

2

.0

2

5

0

3.0

12.58

PRINT

F

E

E

D

1

2

3

4

5

00927

Loading...

Loading...