Plus 42 - 45 - 50 - 55

09-2008

30

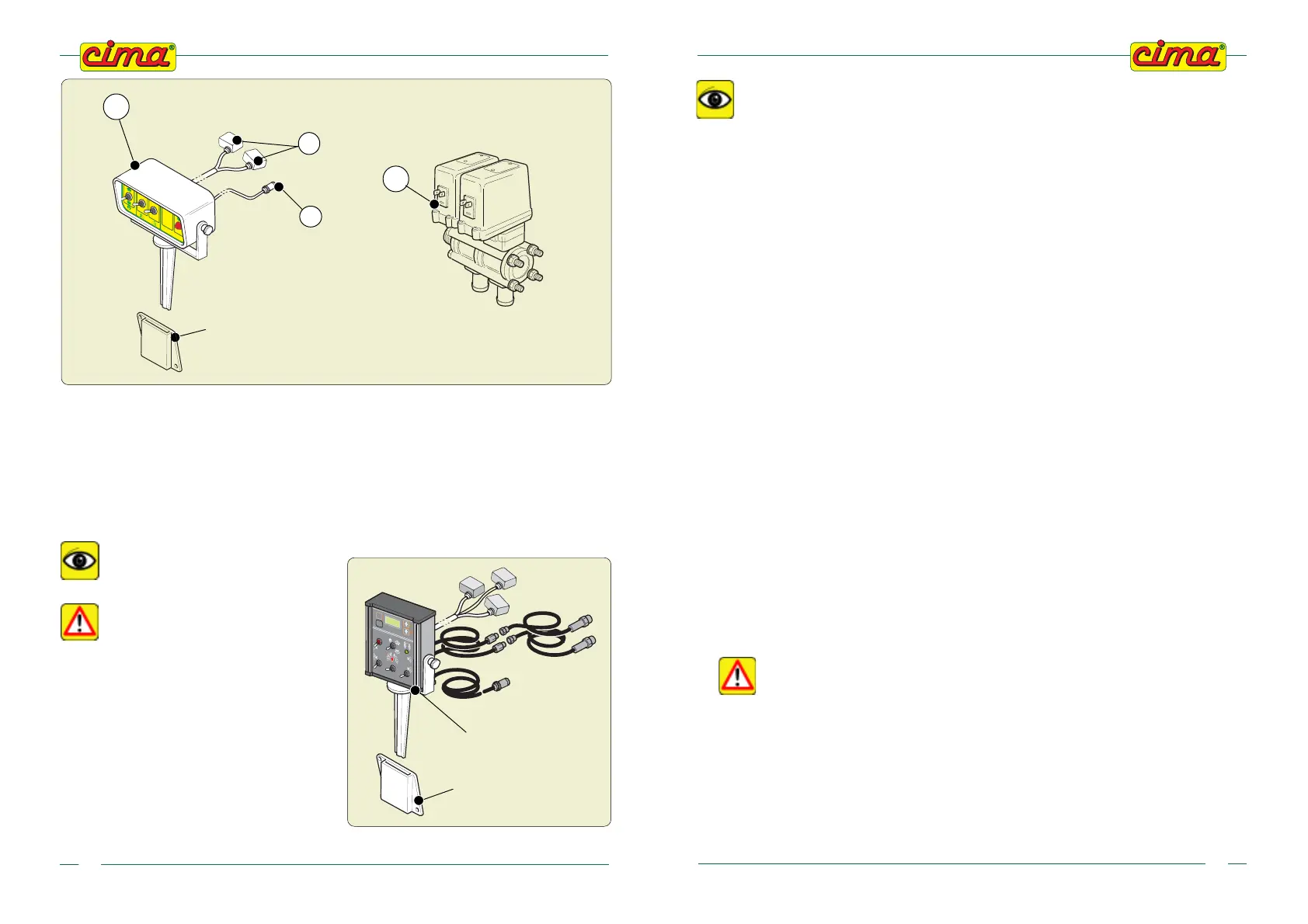

ELECTRICAL

CONTROL

PANEL

TO THE

SERVICE

SOCKET

MOUNTING

BRACKET

E10

E9

®

+

-

ON

R

e

m

o

t

e

C

o

n

t

r

o

l

HO

2

ON

OFF

OFF

Pump

00085

TO THE ELECTRICAL

DISTRIBUTOR (E9)

W2

W1

00086

IN CASE OF A PIPE BURST:

1 - Stop the tractor and remove the key from the control panel.

2 - Close the electrovalves (E9), the switches on the control panel (E10) must be on OFF.

3 - Place the lever of the 3-way tap (P6) in position "d".

4 - Replace the broken pipe (for the elimination of these parts, please follow the current regulations).

5.3.3 - E.P.A. Control Unit

Act in a similar way as indicated for installing the electric control power plant (E10)

m

.

A

U

T

M

A

N

O

N

P

R

O

C

L

R

ON

O

F

F

0

L

H

A

C

O

N

F

IG

2

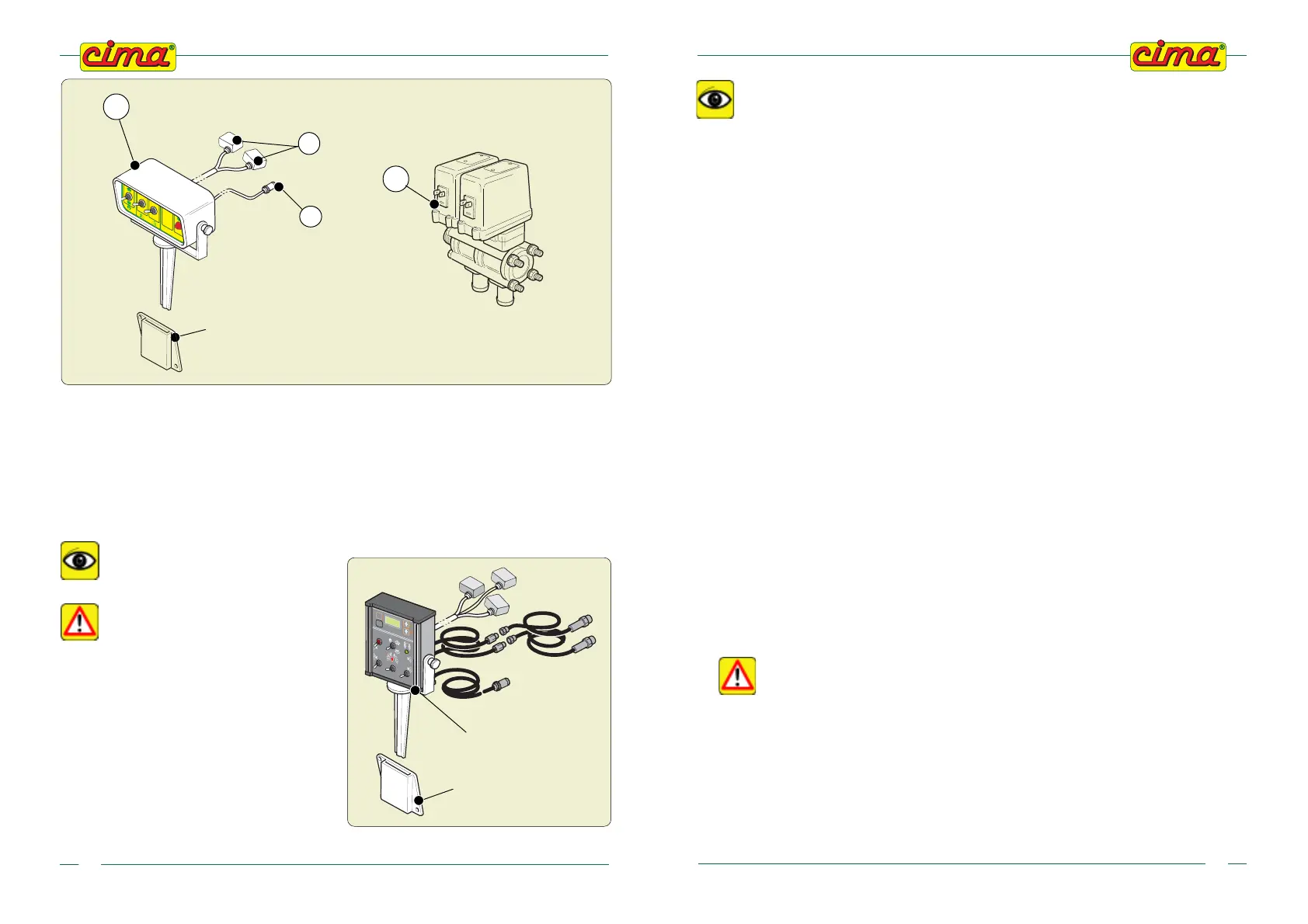

MOUNTING

BRACKET

E.P.A.

CONTROL UNIT

00930

(see Paragraph 5.3.2.)

Position the electric cables in such

a way to prevent them from getting

torn during the treatment.

09-2008

Plus 42 - 45 - 50 - 55

39

The filter must always be below the level of the water to be loaded. The piping must

never be above the pump’s suction point and must never be excessively bent in

the vertical direction.

8. Through the secondary filler BS, pour approximately 15~20 litres of water into the tank: the quantity

must be sufficient to FILL the piping and ACTIVATE the pump to start the recycle.

9. Activate the power take off (PTO) and take it to a rotation speed of at least 500 RPM.

10. When the pump has started the circulation of the water poured, close tap (P2) (o P15) (lever on

“c”) to start up the filling.

11a. WITH MEDICINAL MIXTURES OR LIQUID PRODUCTS (WITHOUT MIXER DEVICE).

11a1 Pour the mixture of medicinal envisaged through the main filler (BP), together with the water

used to wash the canister of product and the tools used in the preparation.

11a2. Close the main filler (BP) of the tank.

11a3. After completing the filling, disengage the PTO

11a4. Close the tap (P6) setting the lever in position “c”.

11a5. Disconnect the filler piping and replace the stopper on the pump.

11a6. Open the faucet (P2) (or (p15) by putting the lever on position “a”

11a7. Open the tap (P6) setting the lever in position “a”

11b. WITH POWDER PRODUCTS: UTILISING THE MIXTURE DEVICE

11b1. Pour the dose of medicinal in powder form foreseen for each loading into the main filler (BP)

of the tank.

11b2. Close the main filler (BP) of the tank.

11b3. Open the cock (P12) (lever on “a”).

11b4. Wait for the filling to be completed.

11b5. Close the cock (P12) (lever on “c”).

11b6. Disengage the power take off (PTO).

11b7. Close the faucet (P6) (lever on “c”)

11b8. Disconnect the filler piping and replace the stopper on the pump.

11b9. Open the faucet (P2) (or (p15) by putting the lever on position “a”

11b10.Open the tap (P6) setting the lever in position “a”

12. Engage the Power Takeoff and move to the treatment place, keeping the Power Takeoff running

rate at least 500 RPM during all the way.

IN THE AREA OF THE TREATMENT

13. Disengage the power take off (PTO) and rest the machine on the ground.

14. STOP THE TRACTOR AND REMOVE THE KEY FROM THE CONTROL PANEL.

15. Make sure that the fan is stopped. Hook the fan to the servo amplifier as indicated at point 8.1.b.

16. Start the tractor, always observing the safety norms.

17. Lift the unit. Engage the Power Takeoff and set it up to a running rate of at least 500 r.p.m., in order

to carry out a further agitation.

18. CARRY OUT THE TREATMENT (See the paragraph 10.3).

Loading...

Loading...