Safety

Qualified personnel

• Make sure all personnel tasked with work on the pump

have read and understood this manual and all other appli-

cable documents, especially the safety, maintenance and

repair information, before they start any work.

• Organize responsibilities, areas of competence and the

supervision of personnel.

• Make sure trainee personnel only work on the pump under

supervision of specialist technicians.

• All activities may only be carried out by specialist personnel

with the required qualifications:

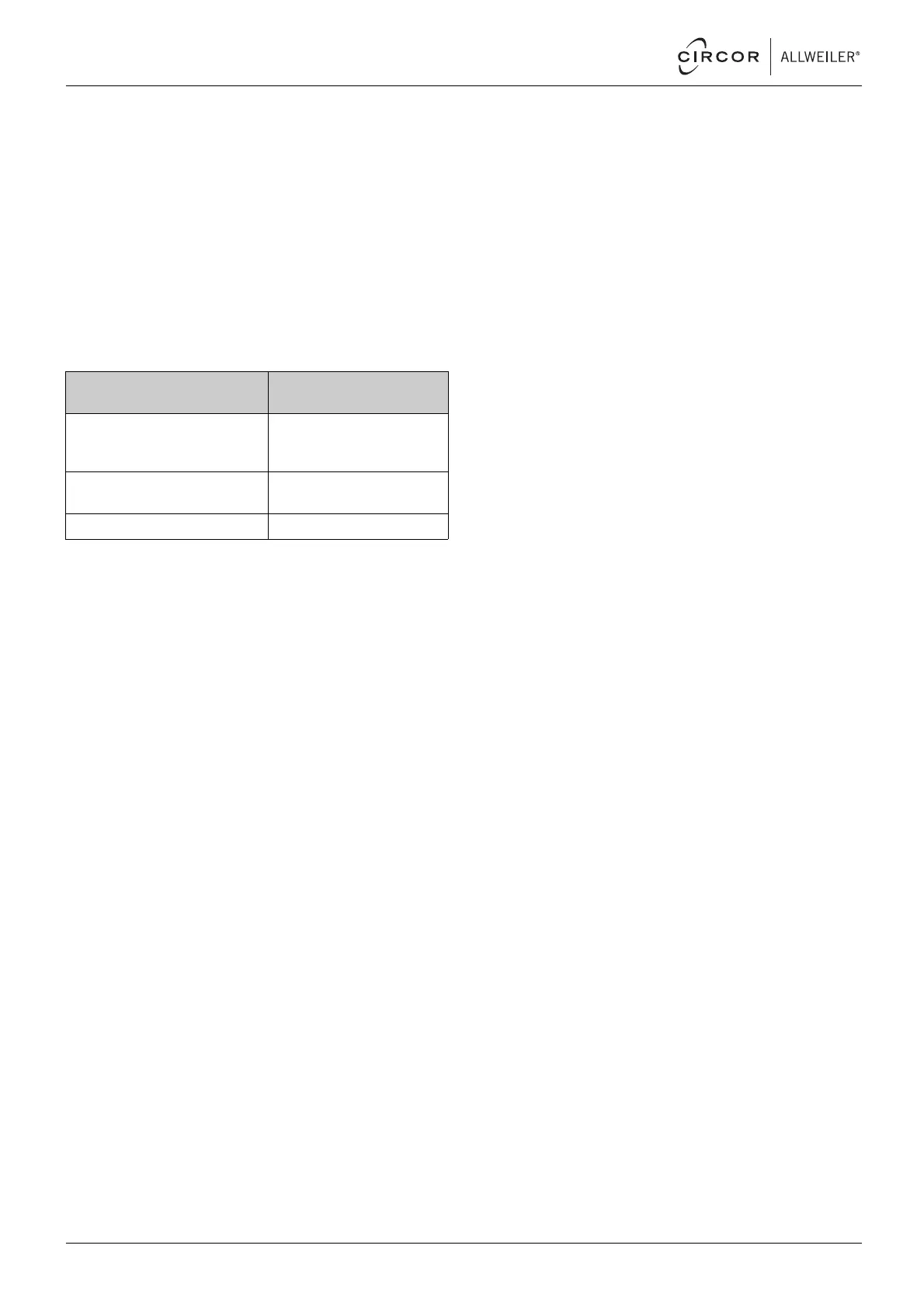

Activities Required personnel

qualifications

Mechanical work

(installation, repairs,

maintenance)

Mechanic

Electro-technical work

(electrical installation)

Qualified electrician

All other work

Instruction from operator

Safety equipment

• Provide the following safety equipment and verify its func-

tionality:

– For hot, cold and moving parts: on-site safety guards

for the pump

– For possible electrostatic charges: provide the neces-

sary grounding

Warranty

• Obtain the manufacturer’s approval prior to carrying out

any modifications, repairs or alterations during the warranty

period.

• Only use genuine parts or parts that have been approved

by the manufacturer.

Drive system

For pumps delivered without a drive system, comply with the

following requirements for the drive system:

• When using three-phase asynchronous motors, observe

IEC 60034-30-1.

• Power of the drive according to EN ISO 5199 is recom-

mended (EN ISO 5199 also applicable for drives of screw

pumps).

• When using combustion engines, consult Allweiler.

• For pumps with stub shaft, connect drive system and pump

directly with stub shaft.

• Use elastic coupling according to DIN 740-2.

• Use coupling guard with the following requirements:

– Fastening elements must be connected to the pump

unit in undetachable design (cannot get lost).

– Safety distances against the reaching of hazardous

areas according to EN ISO 13857 must be complied

with.

2.2.3 Obligations of personnel

• All directions given on the pump must be followed (and kept

legible), e.g. the arrow indicating the direction of rotation

and the markings for fluid connections.

• Pump, coupling guard and components:

– Do not step on them or use as a climbing aid

– Do not use them to support boards, ramps or beams

– Do not use them as a fixing point for winches or sup-

ports

– Do not use them for storing paper or similar materials

– Do not use hot pump or motor components as a heating

point

– Do not de-ice using gas burners or similar tools

• Do not remove the safety guarding for hot, cold or moving

parts during operation.

• If necessary, protective equipment that is appropriate for

the respective assignment must be used:

–Helmet

– Safety shoes

– Safety goggles

– Gloves (min. protection class 3/C)

– Other protective equipment depending on the

(pumped) liquid

• Only carry out work on the pump while it is not running.

• Isolate the motor from its supply voltage and keep it locked

in that state when carrying out any fitting or maintenance

work.

• Reinstall the safety equipment on the pump as required by

regulations after any work on the pump.

8 NI series BA-2021.06 en-US 550 113 – 146-900/E

Loading...

Loading...