DUST EXTRACTION

A dust extraction outlet is provided which may

be connected to a vacuum cleaner or a dust

extraction device, such as the CLARKE CDE35,

when the need arises.

Please see your CLARKE dealer for details.

TIPS ON USING YOUR BANDSAW

It should be understood that this machine is

primarily designed for freehand cutting - i.e. to

cut shapes in relatively thin wood. It is NOT

designed for cutting plastics, or any other

material. However, to increase its versatility, it is

possible to cut straight lines using either the Mitre

Gauge or Parallel Fence, as described below.

For all cutting operations, the upper guide block

and blade guard assembly should be adjusted

to be just clear of the work being cut. Not only

does this provide the best safety for the operator,

but it also brings the blade guides closer to the

work giving more accurate results and better

control.

Use both hands to feed the workpiece into the

blade. The work must be held

flat on the table at all times

to prevent binding of the

blade. Use a steady

even pressure just

sufficient to keep

the blade cutting.

Always use a rip fence or mitre guide where

possible to eliminate any sideways slip of the

work. This is most important when the table is

tilted to an angle.

Always plan your work ahead, and aim to make

a complete cut in one pass, rather than stopping

a cut, which requires the workpiece to be

withdrawn. The tradesmans’ rule is “measure

twice, cut once”. It is best to finish a cut in one

continuous operation, but frequent backtracking

may be necessary.

If you do have to withdraw the workpiece, switch

off the bandsaw first, by pressing the OFF (O)

button, and allow the blade to come to a

complete stop before backing it out of the cut.

C. Blade Guide Height

The Upper Blade Guide must be adjusted

according to the thickness of the workpiece to

be cut.

Slacken off the Guide Block using knob (L, Fig. 1)

and adjust the height of the guide so that it is no

more that 5mm higher than the workpiece, then

secure in this position.

Check this setting and readjust if necessary

before each cut.

OPERATION

Check to ensure that all safety precautions have

been complied with before switching on the

mains supply and pressing the ON button (1).

Allow the blade to come to full speed.

Ensure the workpiece is held firmly against the

table at all times. (See ‘Tips On Using Your

Bandsaw’ which follows).

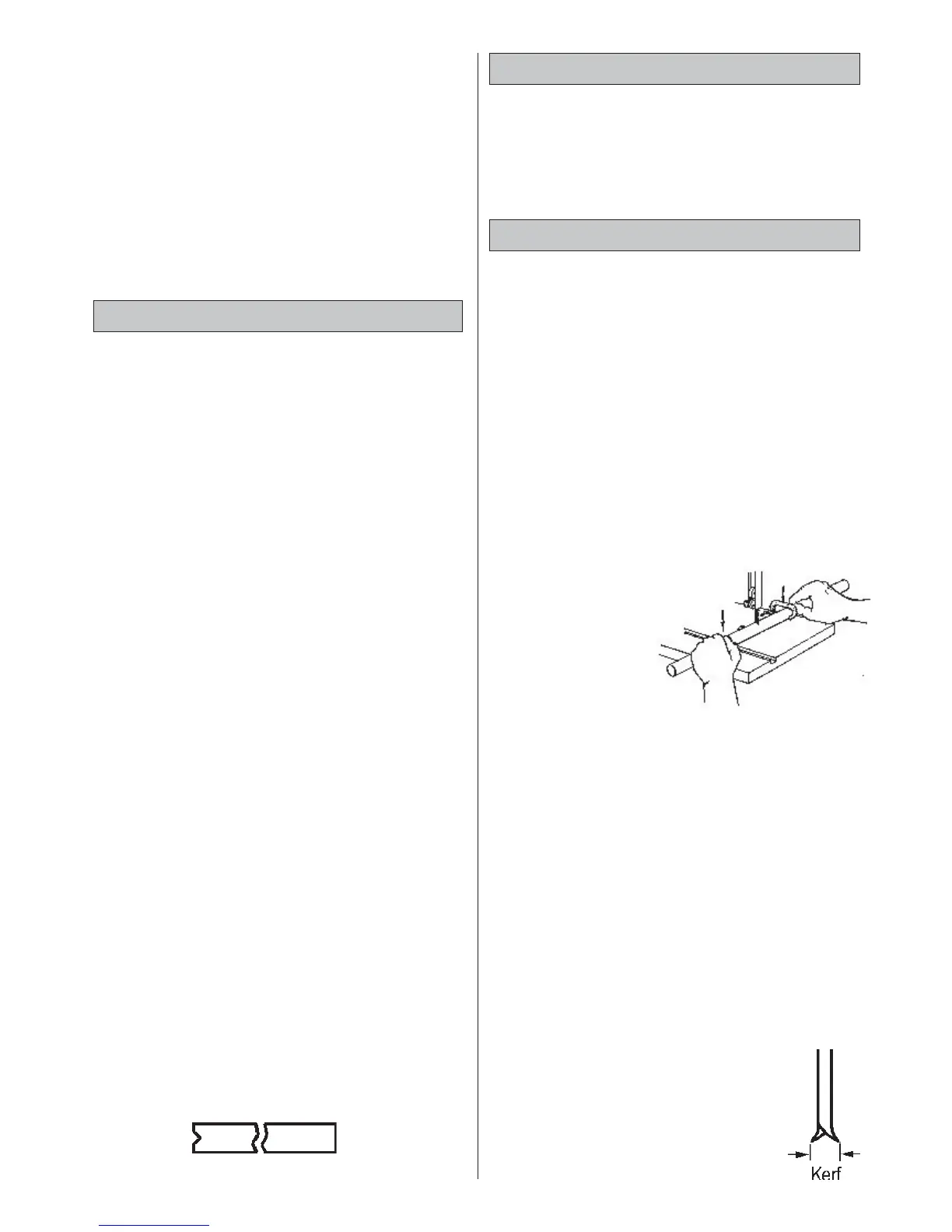

Remember that round stock should be clamped

as shown in Fig. 5, to ensure it cannot roll.

Always feed the workpiece at a rate that allows

the blade to cut without difficulty.

Whenever new adjustments are made, you

should always make a trial cut in order to check

the settings.

Parallel Fence and Mitre Gauge

Always use the parallel fence or mitre gauge on

all cuts for which they are intended, to prevent

the blade from running off the cutting guide line,

particularly when working with a tilted table.

When using the parallel fence, there must be

sufficient clearance between the blade and

fence so as to allow the operator to hold the

workpiece firmly, between fence and blade,

without endangering the hand. The other hand

is used as a guide/support ONLY, the hand

between fence and blade being the hand that

feeds the workpiece into the blade.

If the clearance is small, then a push stick should

be used; i.e the workpiece is fed into the blade

with a pushstick.

NOTE:

Remember that the blade removes

material during the cut. This gap

created by the blade is called the

‘kerf’, and must be allowed for

when cutting to exact sizes. Plan

your cut so that the kerf is the scrap

side of the lines you wish to cut. If

necessary, allow a little more for

finish sanding.

Pushsticks can easily be made using a piece of wood

1/2”x1” x 12” , with a 1/4” notch cut in one end, as

shown below.

Fig. 6

Fig. 5

8

Loading...

Loading...