Grasp the Arm and attempt to lower it, whilst simultaneously turning the knob ‘A’,

anticlockwise. Turn the knob until the required rate of descent is achieved.

The nut on the stem of Knob ‘A’ may be used to lock the valve in any particular

position, thereby ensuring the rate of descent, and hence cutting pressure is

constant - for repetitive work.

Preparation for Use

Warning! Do not attempt to start the machine until ALL the following checks

and adjustments are carried out. Ensure the plug is disconnected from mains.

To achieve the best performance, and to maintain the maximum level of safety,

the blade must be set up correctly.

a. Blade tension must be correct to ensure the blade circulates correctly and

to prevent the blade from wandering during the cutting operation

b. The blade cutting area is fitted with blade guides, which support the blade

whilst cutting. It is VITAL that these guides are correctly adjusted.

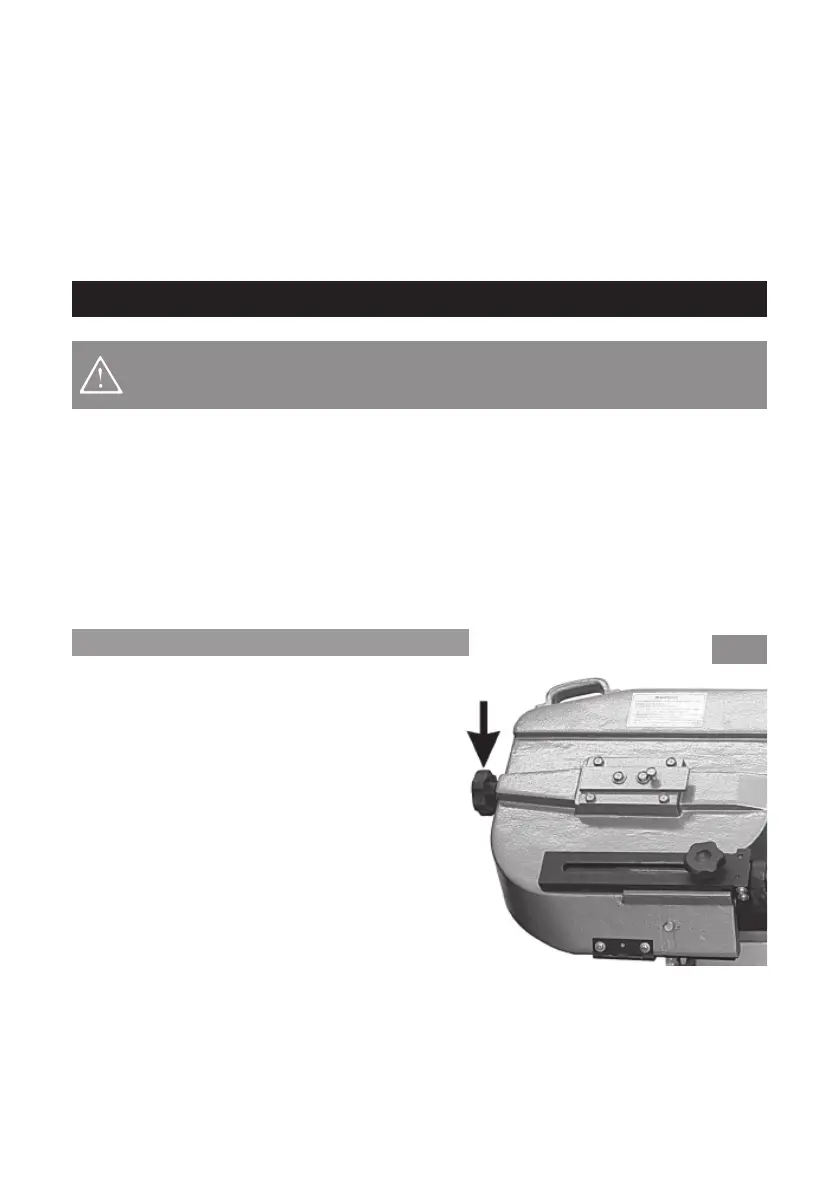

A. Tensioning the Saw Blade

Turn the Blade Tension Adjusting Knob,

arrowed in Fig. 6, clockwise to increase

tension, anticlockwise to decrease.

The knob is provided with a spring lock to

ensure it does not move during use or

whilst the bandsaw is being moved.

The blade needs to be tight enough to

give a straight cut without allowing it to

wander or slip, but must not be too tight

so that it is rigid, there must be a certain

degree of flexibility.

The correct tension is 700-900kgs, as

measured with a blade tension gauge.

Fig.6

To tension without a gauge, slacken off adjuster so that the blade sags, then

screw in again (clockwise) until all sag has been eliminated. Finally, turn the

adjuster a further two complete turns. See ‘Maintenance’ for blade installation

and tensioning a new blade.

If the saw is not being used for some time, eg. at the end of a working day, we

recommend that you relieve the tension on the blade.

10

Loading...

Loading...