If the resulting weld looks irregular or messy, or shows signs of

porosity or slag contamination, you have almost certainly failed

to achieve the correct combination. Do not worry as practice

will soon cure this, and the following tips on welding pitfalls should

help to improve your technique quite quickly.

WARNING: Never look at welding arc, it can seriously

damage your eyes. Always use the face shield provided

or any proper welding mask.

HEALTH WARNING: When welding always make sure

there is adequate ventilation in the working area as the

welding process gives off toxic fumes.

7.0 WELDING PITFALLS

The arc welding technique is an acquired skill and will almost

certainly require considerable practice before perfect results are

obtained. The diagrams below should help to explain pitfalls in

your technique and how to overcome them.

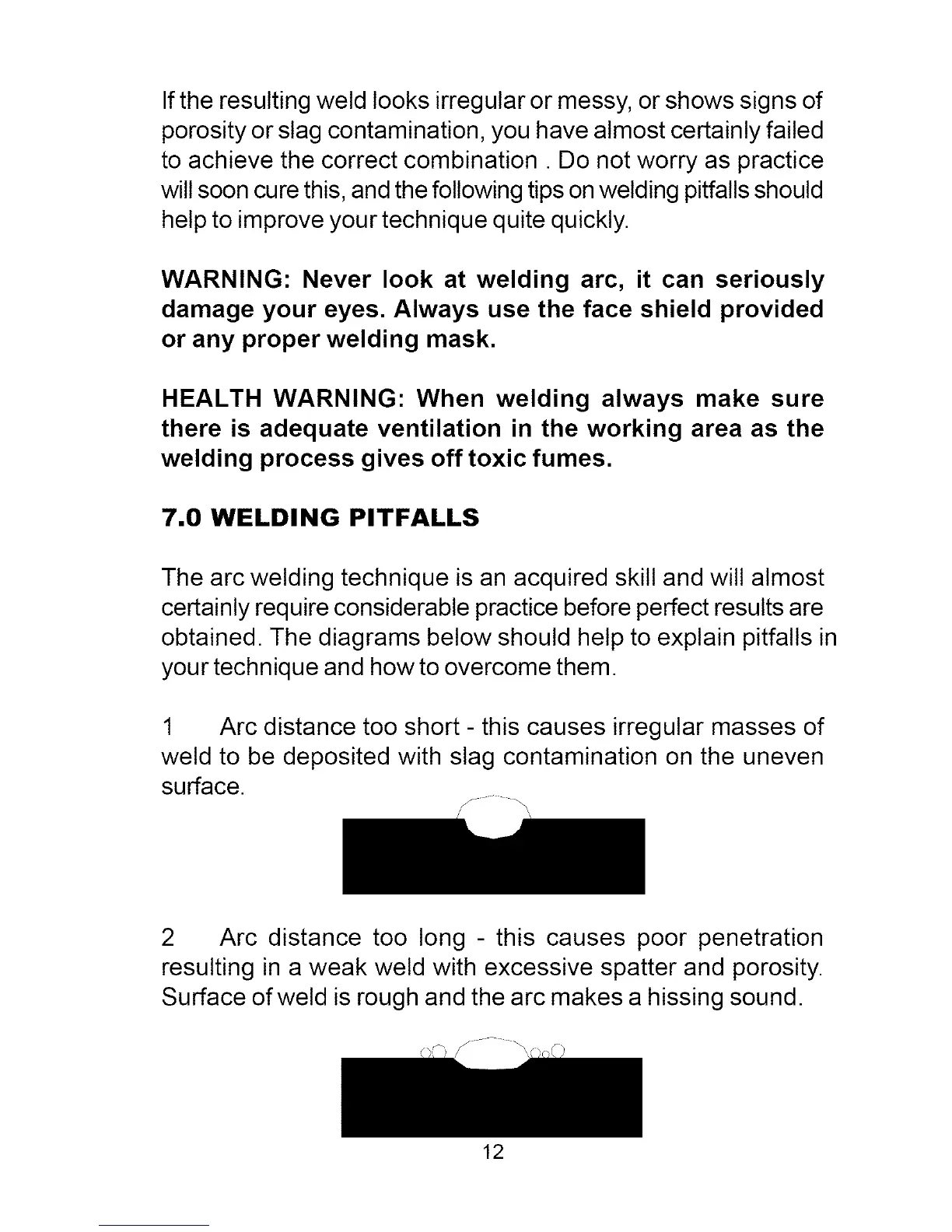

1 Arc distance too short - this causes irregular masses of

weld to be deposited with slag contamination on the uneven

surface.

2 Arc distance too long - this causes poor penetration

resulting in a weak weld with excessive spatter and porosity.

Surface of weld is rough and the arc makes a hissing sound.

12

Loading...

Loading...