Adjustments

4-6

750-297

Profire E/LNE Series Manual

of change. The closer the rod to the hub of the lever, the less distance it will travel.Increasing the lever length on the

damper, metering unit and valve(s) decreases flow rate.

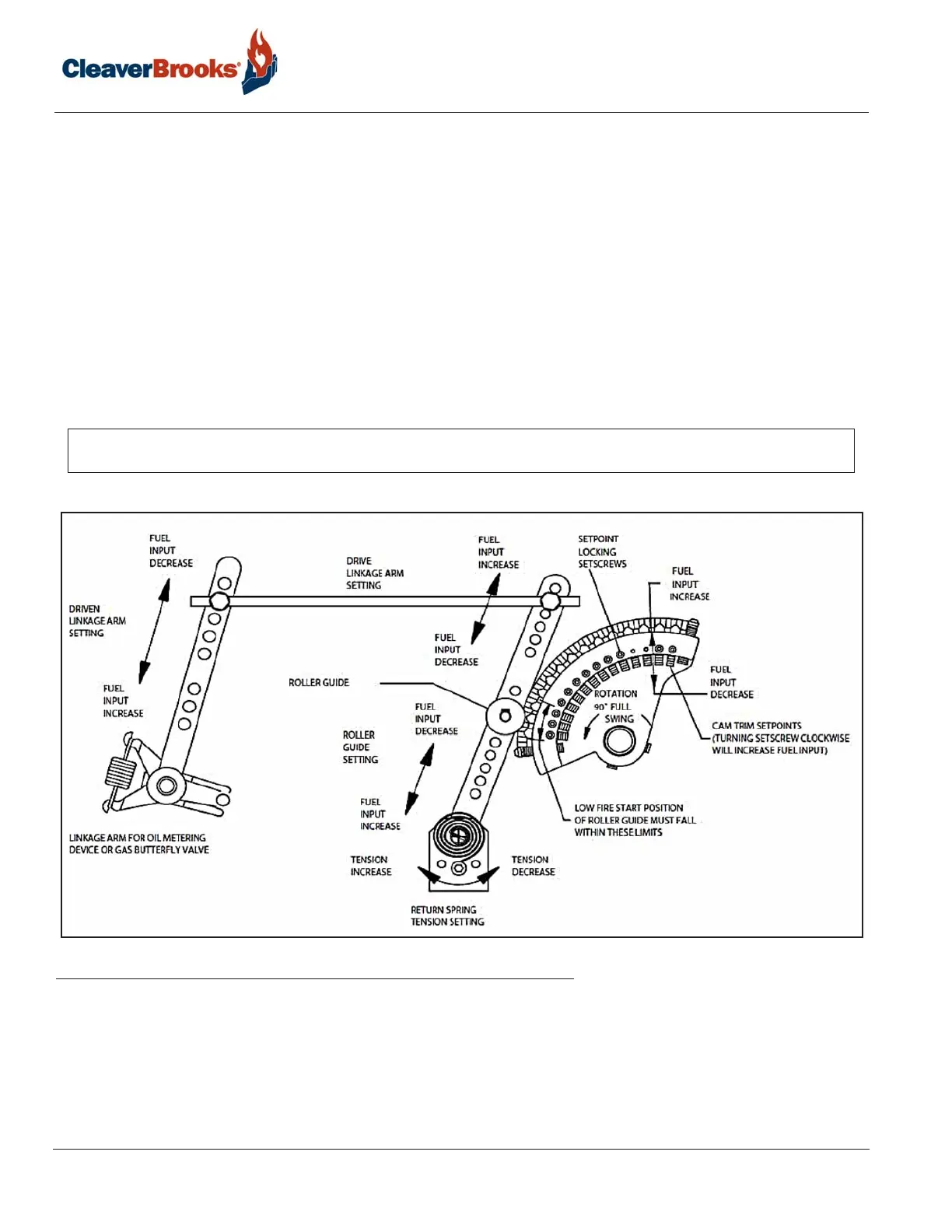

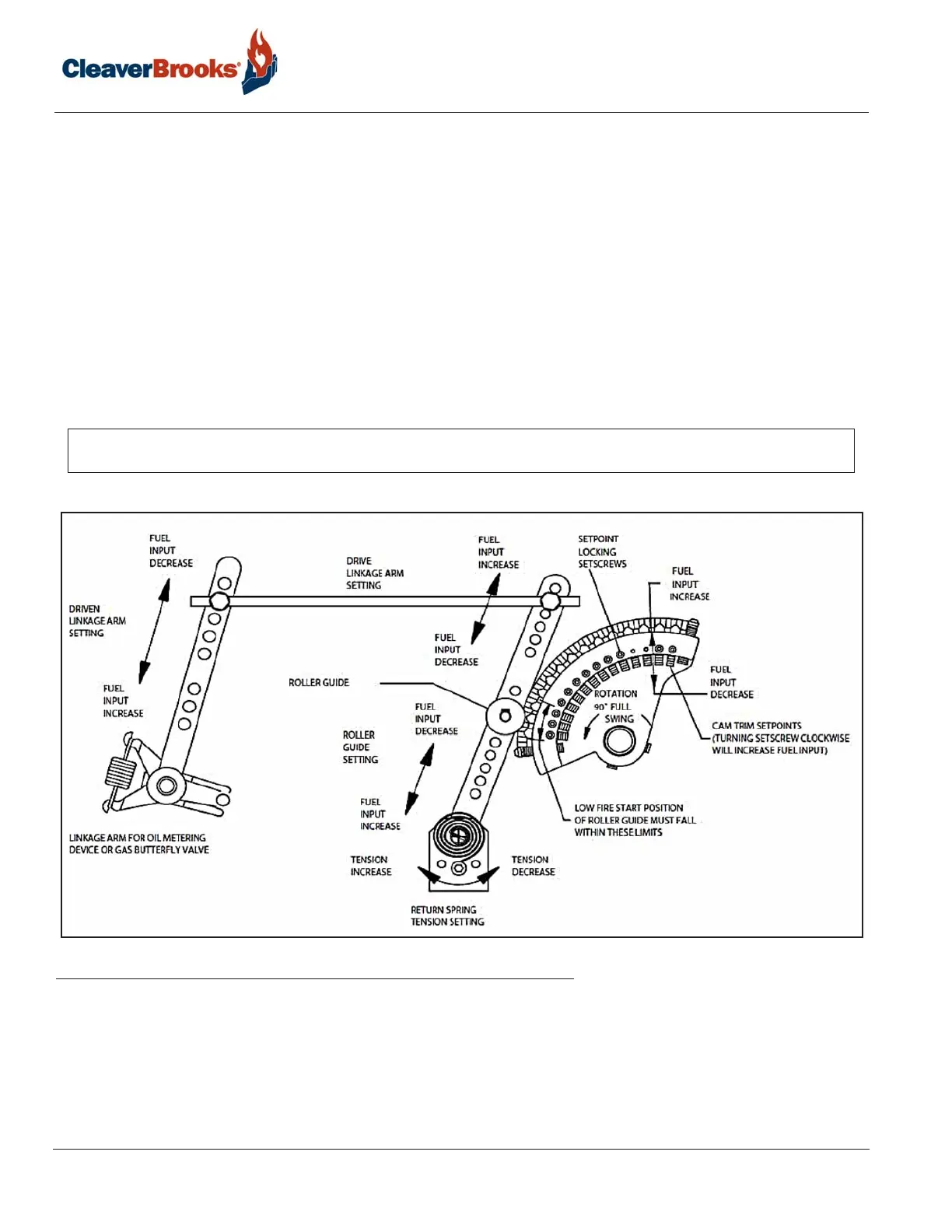

4.7 — Cam Trim Adjustment

After low and high fire adjustments are complete, final adjustment is made with the cam assembly to obtain a good air/

fuel ratio throughout the entire firing range.The input of combustion air is fixed at any given point in the modulating

cycle. The fuel input may be varied to obtain correct flue gas readings. The adjustment is made to the metering cam by

means of the 14 adjusting screws which are turned in (clockwise from the hex-socket end) to increase the flow of fuel,

and out (counterclockwise from the hex-socket end) to decrease it. A 3/32” hex key is required. It will be necessary to

cut off the short end of a hex key to approximately 3/8” to adjust the first two socket head setscrews at the low fire

position. Take a combustion analysis at various points of the cam profile. Adjustment can be made without cycling the

burner, then operate the automatic modulating cycle to assure satisfactory results. Tighten the locking setscrews.

FIGURE 4-1. Cam Trim Adjustment

4.8 — Parallel Positioning Adjustment

For parallel positioning systems refer to the control manufacturer's documentation and to the accompanying wiring

diagram for information on adjusting the system. In a properly tuned parallel positioning system the independent

NOTE: It is essential that the cam spring, cam follower bearing wheel, and cam follower arm at the pivot point be greased

sparingly every month to ensure smooth operation of the cam assembly. Regular automotive bearing grease should be used.

Loading...

Loading...