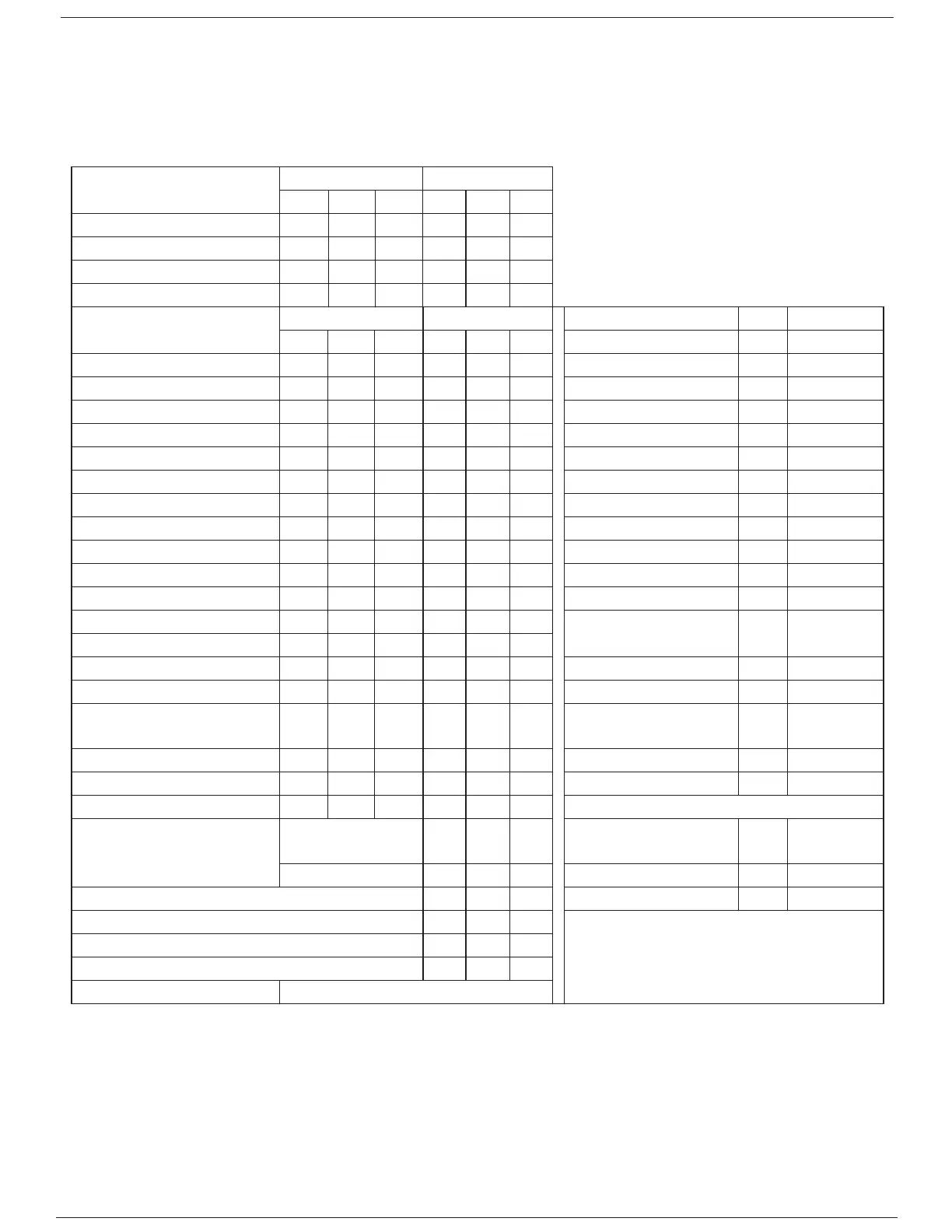

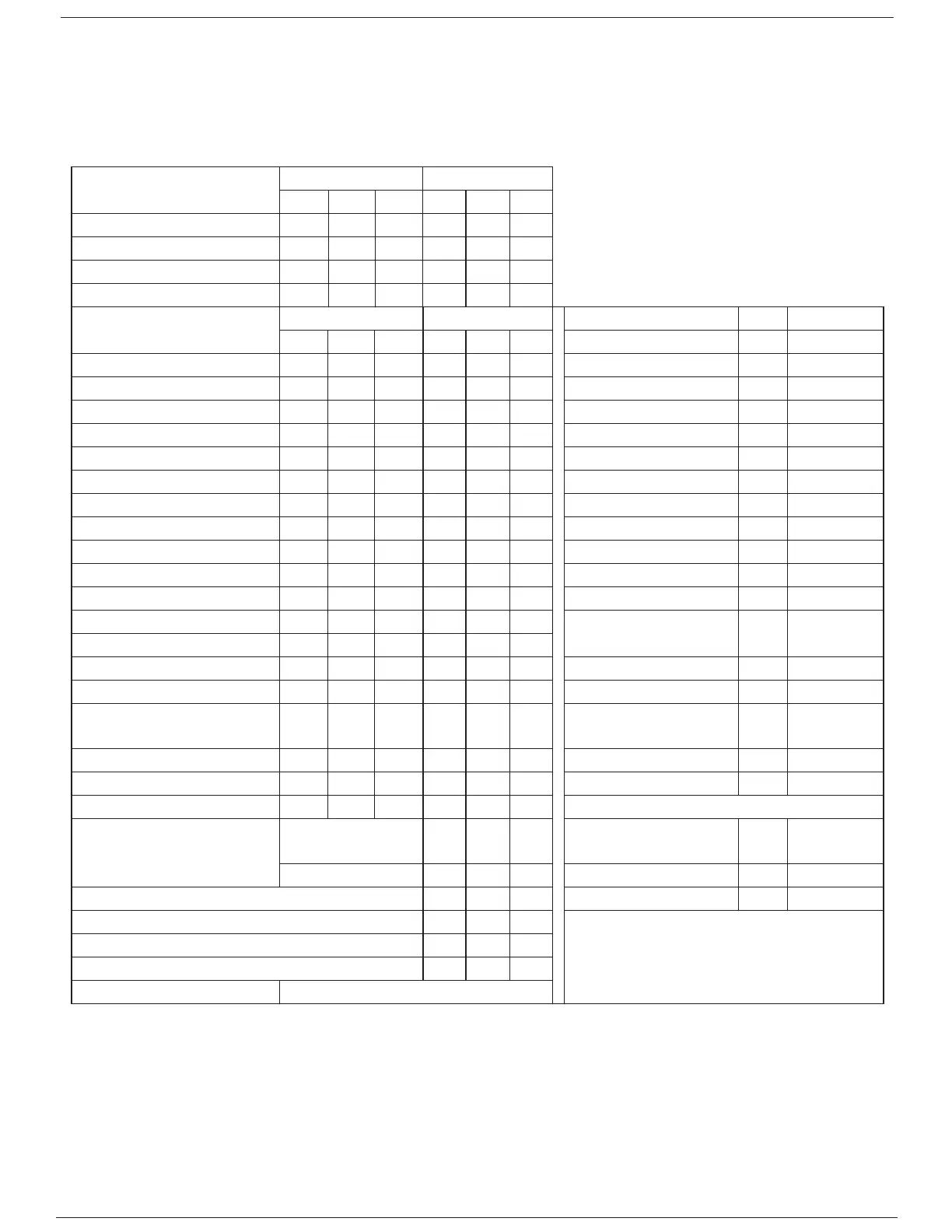

Startup/Service Report

The following information should be filled in by the service technician at startup or after any adjustment to the burner.

A copy of the startup report MUST be forwarded to C-B in order to validate the warranty of the burner.

Burner Model _______________ Serial Number_______________ Startup Date_______________

Adjusted by:

Date:

Accepted by:

(Signature Required)

Electric Motors

Voltage Amperage

L1 L2 L3 L1 L2 L3

Control Voltage

Blower Motor

Air Compressor

Air-Oil or Metering

Test Conducted

Gas Oil Control Check Test Set Point

Low 50% High Low 50% High

Low Water Cutoff

Firing Rate MMBtu/gph Aux. LWCO

Stack Temp (gross) º F High Water Cutoff

Room Temp º F Operating Limit

O2% High Limit

CO% Operating Control

CO (PPM) Stack Temp Interlock

NOx (PPM) Flame Failure

Smoke (Bacharach) Combustion Air Switch

Combustion Eff. % High Purge Switch

Stack Draft “ W.C. Low Fire Interlock

Furnace Pressure “ W.C. Oil Pressure Switch

Blast Tube Pressure “ W.C. Oil Valve w/P.O.C.

Interlock

Steam Pressure PSIG

Water Temp º F High Gas Pressure Switch

Supply Oil Pressure PSIG Low Gas Pressure Switch

Return Oil Pressure PSIG Gas Valve P.O.C.

Interlock

Vacuum Oil Pump “ HG Pilot Turndown Test

Oil Temp Flame Signal Pilot

Atom. Air Pressure (For Low NOx Burners)

Gas Pressure @ Burner

Manifold “W.C.

Inner Manifold Blast Tube Temp

Interlock

Outer Manifold FGR Line Purge Switch

Center Gas Pressure “W.C. FGR Valve P.O.C.

Gas Pressure @ Regulator Inlet PSIG

Gas Pressure @ Regulator Outlet PSIG

Pilot Gas Pressure @ Regulator Outlet “W.C.

Flame Signal Main Low 50% High

Loading...

Loading...