BOILER BOOK CFC-E FEATURES AND BENEFITS

5

linear load tracking, reduced on-off cycling, and reduced electrical consumption.

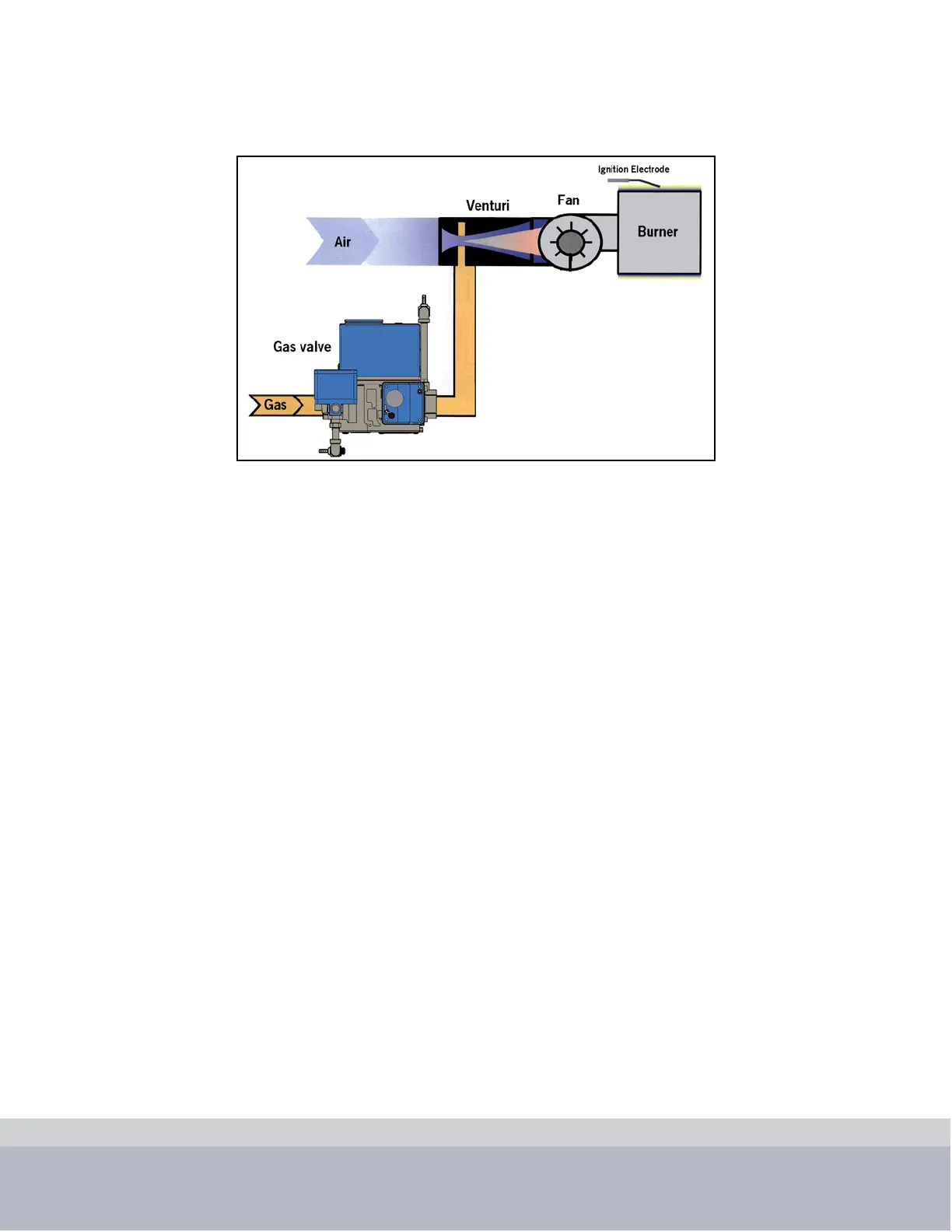

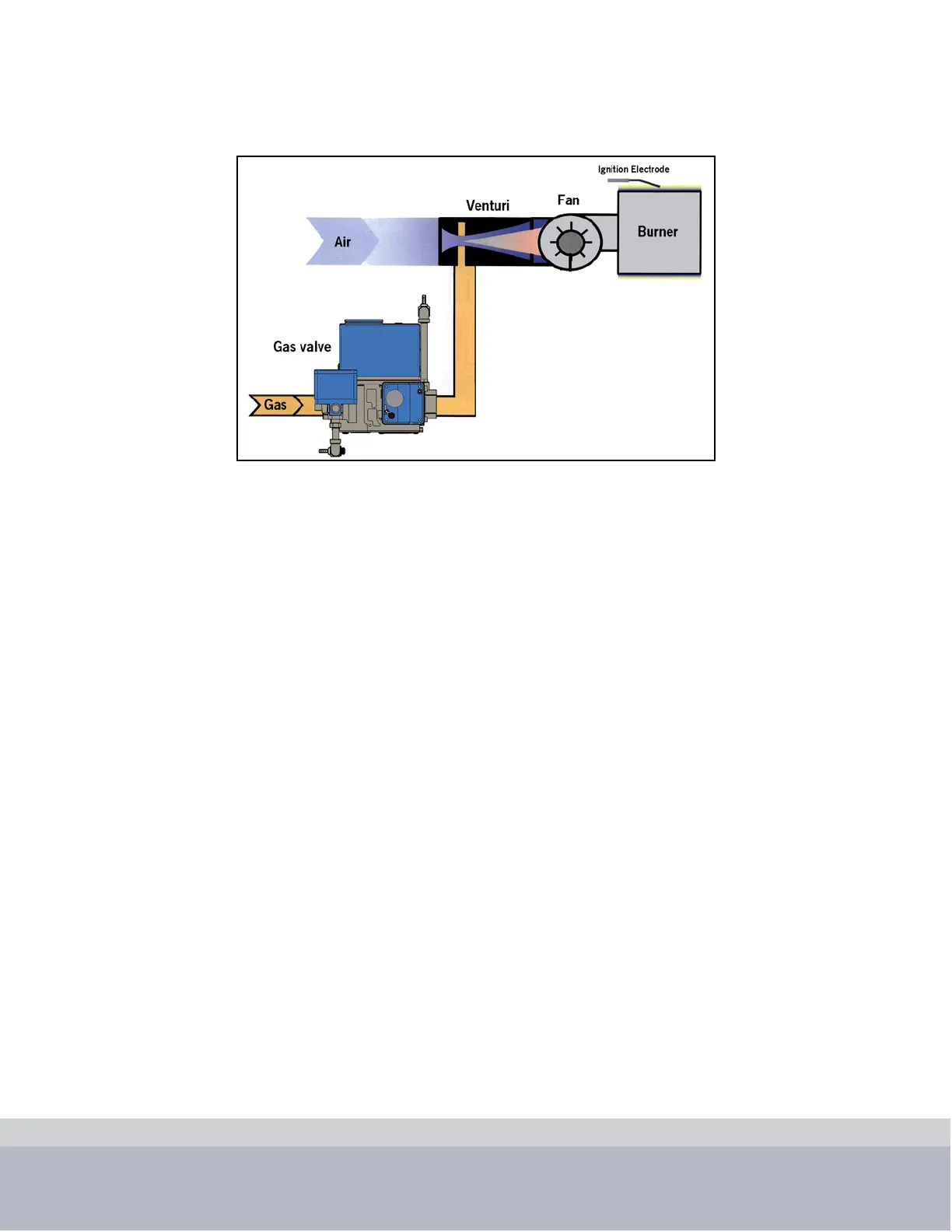

Figure 2. Premix Burner Technology

Designed For Heating Applications

The pressure vessel is designed for 125 psig MAWP (Maximum Allowable Working Pressure) and is

constructed of durable ASTM Grade Steel and Stainless Steel materials. The true counter flow heat

exchanger design equates to optimal heat transfer. The design also prevents hot spots, does not

require a minimum flow for thermal shock protection, and does not require a minimum return water

temperature. In fact, the design carries a 20-year thermal shock warranty.

Because of its design characteristics, the Model CFC-E is well suited for applications utilizing indoor/

outdoor reset controls, radiant floor heating, snow melt systems, ground source heat pump systems

and systems that utilize variable speed circulating pumps. It may also be employed in standard hot

water systems that require higher heated water at colder outdoor temperatures but then require lower

temperatures during warmer heating days, realizing fuel efficiency savings over traditional hot water

boilers.

While the design does not lend itself to the direct supply of potable water, a separate storage tank

with an internal heat exchanger can be employed, as the onboard controls permit domestic water

programming. Therefore, the Model CFC-E can service both hydronic heating and domestic water

source heating.

Dual Return

Two return connections - high and low temperature - allow condensing performance with as little as

10% return water at condensing temperature.

SCAQMD Certified

The CFC-E is certified by the South Coast Air Quality Management District.

Loading...

Loading...