16 P2144BA/EN 2014-08 2144b-en_1_5_bedingt.fm, 09.09.2014

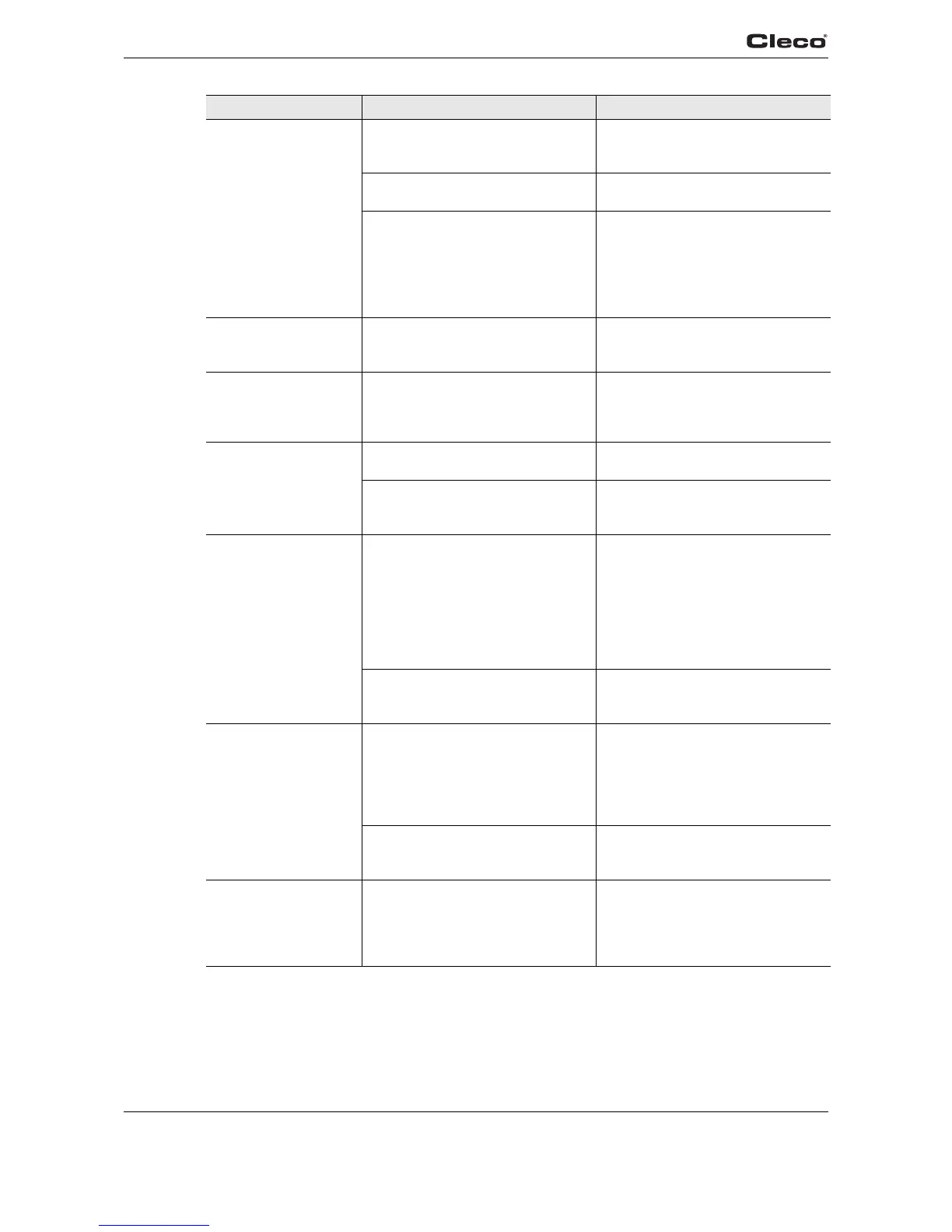

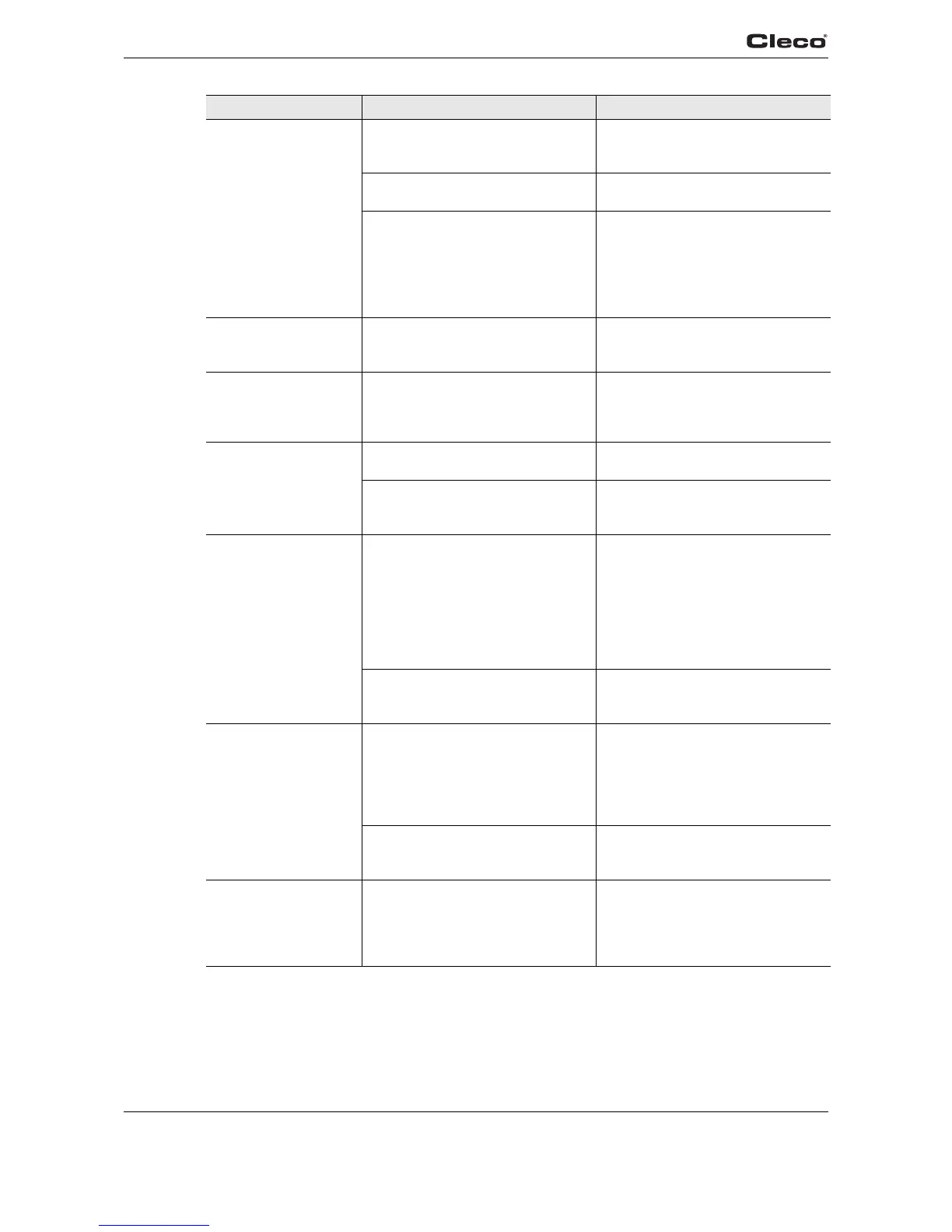

Troubleshooting

8

Tool switches off prema-

turely

Operator releases start switch before

the control stops the tool

Make sure that the operator keeps

the start switch pressed throughout

the entire sequence.

The fastening time exceeds the stan-

dard time by 10 seconds.

Increase the fastening time

Tool exceeds the angle setpoint

Check the fastening sequence to

ensure that the torque shutoff value

and/or angle setpoint are correct.

Adjust as necessary.

Check whether the screwed joint

has changed significantly.

Tool does not change

speed

Speed is the same in all stages used

Make sure that the speed and the

switching angle in the stages are

correct.

LEDs on the tool start to

flash when the reverse

switch is operated.

This is a normal function which is

defined in the default parameters.

Activate or deactivate the check

box Blink Lights when Tool

in Reverse (Advanced > Tool

Setup)

Warning in menu RUN

SCREEN: Offset

Transducer 1/2 NOK

The transducer does not return to a

zero torque vale

Transducer has been overloaded

and must be replaced

Faulty wiring in tool or in cable

Check tool with different cable. The

offset and calibration values can be

checked in the Diagnosis menu.

Warning in menu RUN

SCREEN:

Tool Offline!

Tool has not been accepted in the tool

settings

Check the Tool List menu to make

sure that the tool has been

accepted. If it has not been

accepted, the status will show

Manual acceptance needed.

The correct line must be marked

before the setting can be accepted

in the Tool Settings menu.

A faulty cable will prevent the tool from

being recognized by the nutrunner con-

trol

Repair or replace cable

Different torque display in

the control and external

transducer

Torque calibration factor (Torque Cal.)

in Tool Settings must be adjusted.

Adjust Torque Cal. (Tool Setup >

Tool Settings > Accept) using the

following formula:

New calibration value =

(external value / tool value) × cali-

bration value used

Customer's angle attachment was

added to tool. Tool memory must be

updated.

Reprogram tool memory

Tool cable does not fit in

tool handle

Wrong cable. Tools in use with nutrun-

ner control mPRO400GC use an Air-

LB connector. Connector has different

size to previously used Matrix connec-

tor.

Use the right cable for the tool used

Problem Possible cause Measure

Loading...

Loading...