14

5 Set-up and operation

5.1 Requirements

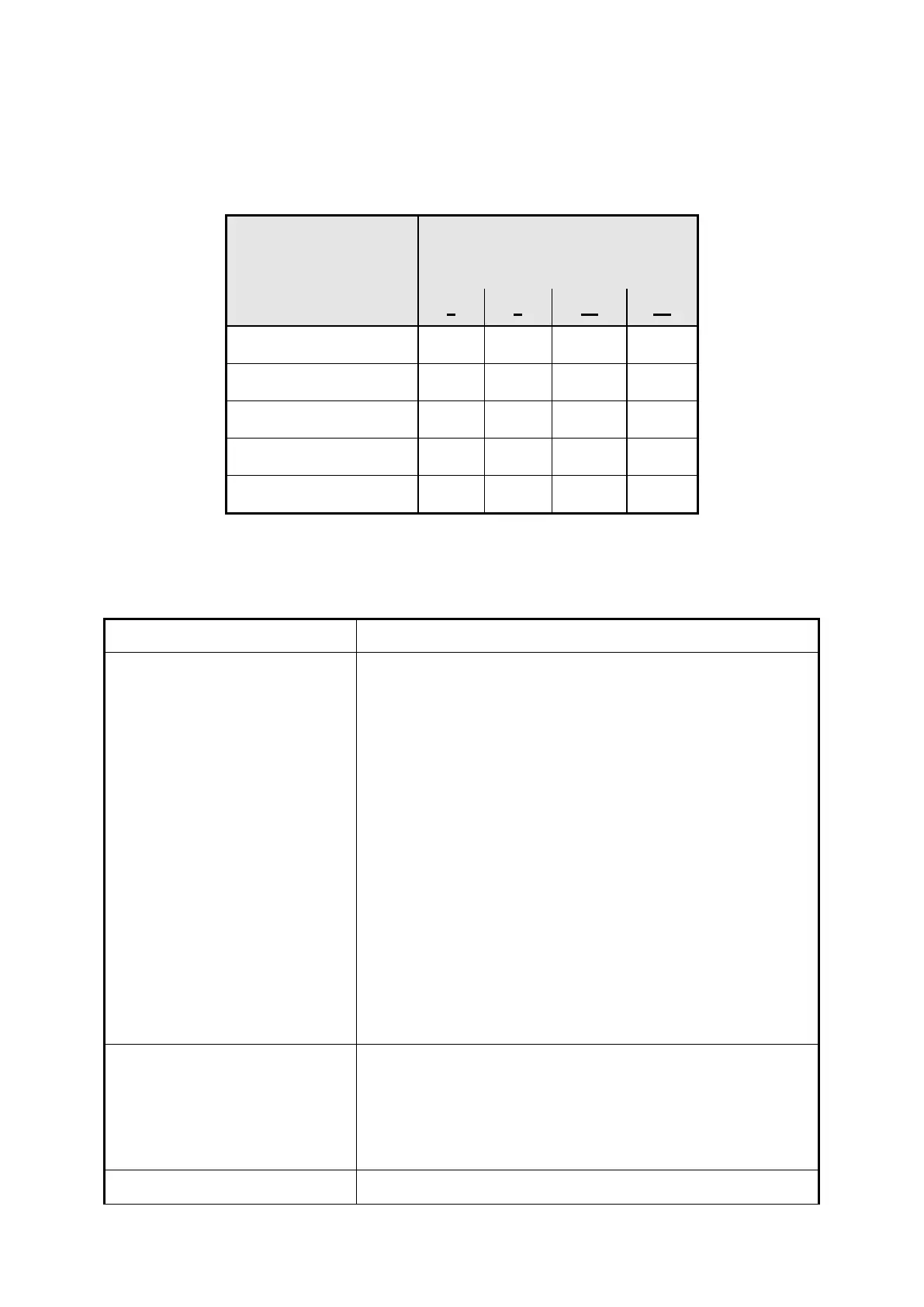

For a proper function of the blast machine, a sufficient air supply is necessary (see table 2).

Nozzle

size [mm]

Air consumption [m

3

/min.]

Pressure at the nozzle [bar]

6 8 10 12

6.5

2.0 2.6 3.2 4.7

8

3.4 4.8 5.4 6.4

9.5

4.8 6.2 7.6 9.0

11

6.4 8.3 10.1 12.0

12.5

8.4 10.7 13.1 15.4

Table 2: Air consumption

5.2 Set-up for initial installation or reinstallation

On an even and firm ground.

(2) Install an air supply for working

pressure indicated on pot.

− Place compressor upwind near blast machine (

contaminated air should enter compressor).

− Start compressor and bring it up to operating temperature (5

to 10min.). Only use compressors whose rating does

exceed the maximum working pressure of the pot!

− Attach airline

(appropriate dimension) with all necessary

gaskets in place to air outlet of compressor and safety lock

couplings.

Escaping air is dangerous and lowers

efficiency!

− Carefully open air valve of compressor to blow debris and

moisture out of attached airline.

− Close air valve.

−

Install an appropriate coupling to air inlet of blast machine

(safety coupling).

− Connect airline to blast machine and safety lock it.

− For trouble free blasting we recommend an air supply free of

oil and water (air cooler with cyclone and automatic drain).

(3) Attach blast hose and nozzle to

blast machine.

− Check gasket of coupling for wear.

− Connect blast hoses to length needed (All gaskets

in place!), attach them to blast machine and safety lock them.

− Choose an appropriate nozzle and attach it to nozzle holder

(4) Install a deadman handle and

− Pneumatic remote control:

Loading...

Loading...