18

− Check airline (air supply) and replace it when it is worn.

−

Check gaskets of couplings for wear and replace them if

necessary.

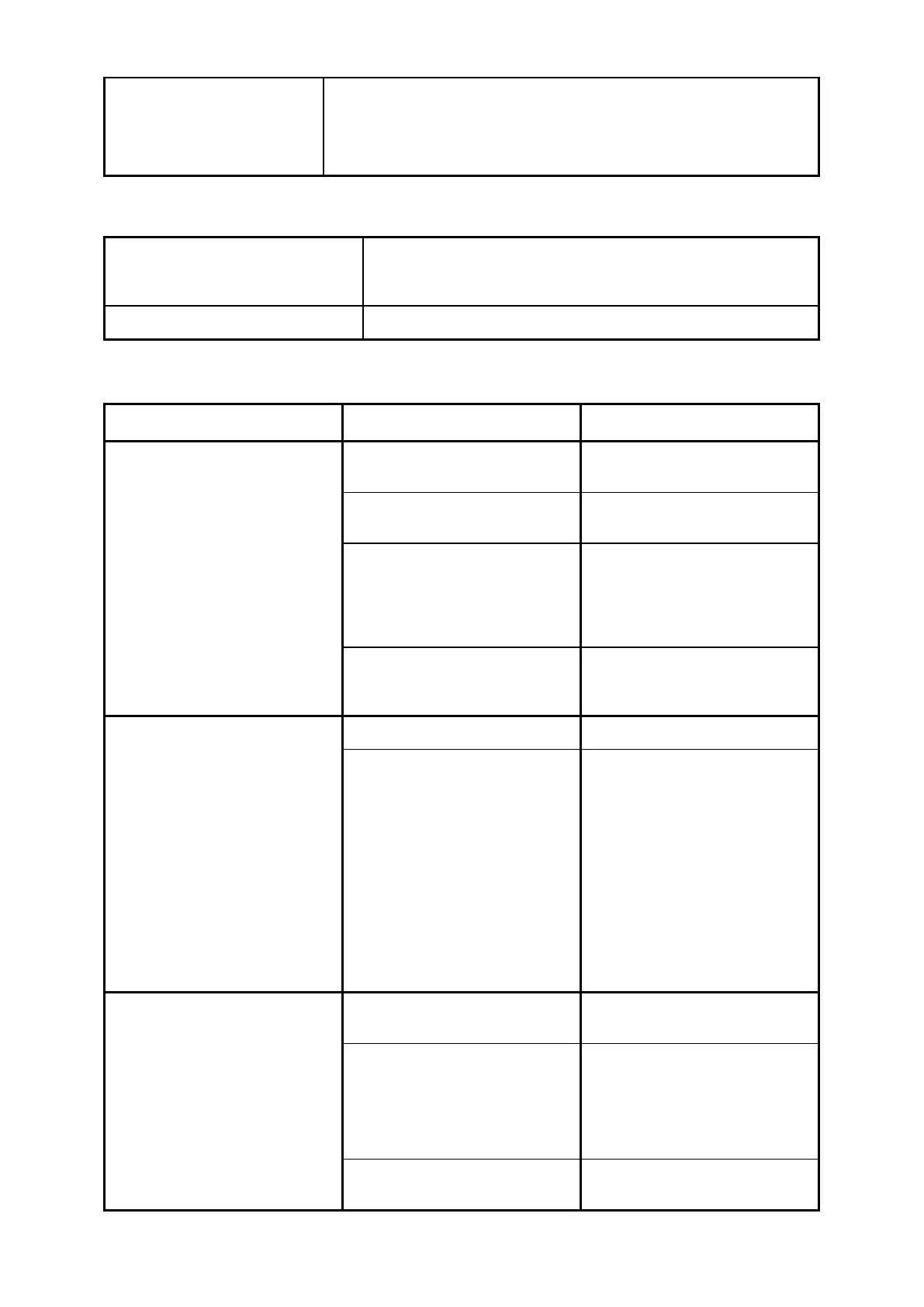

6.4 Monthly check list

(1) Remote control valve RMS-

2000A (RMS 1500+500) or

Check all fittings and connections of remote control valve for

leakage.

Check condition of muffler and corresponding piping.

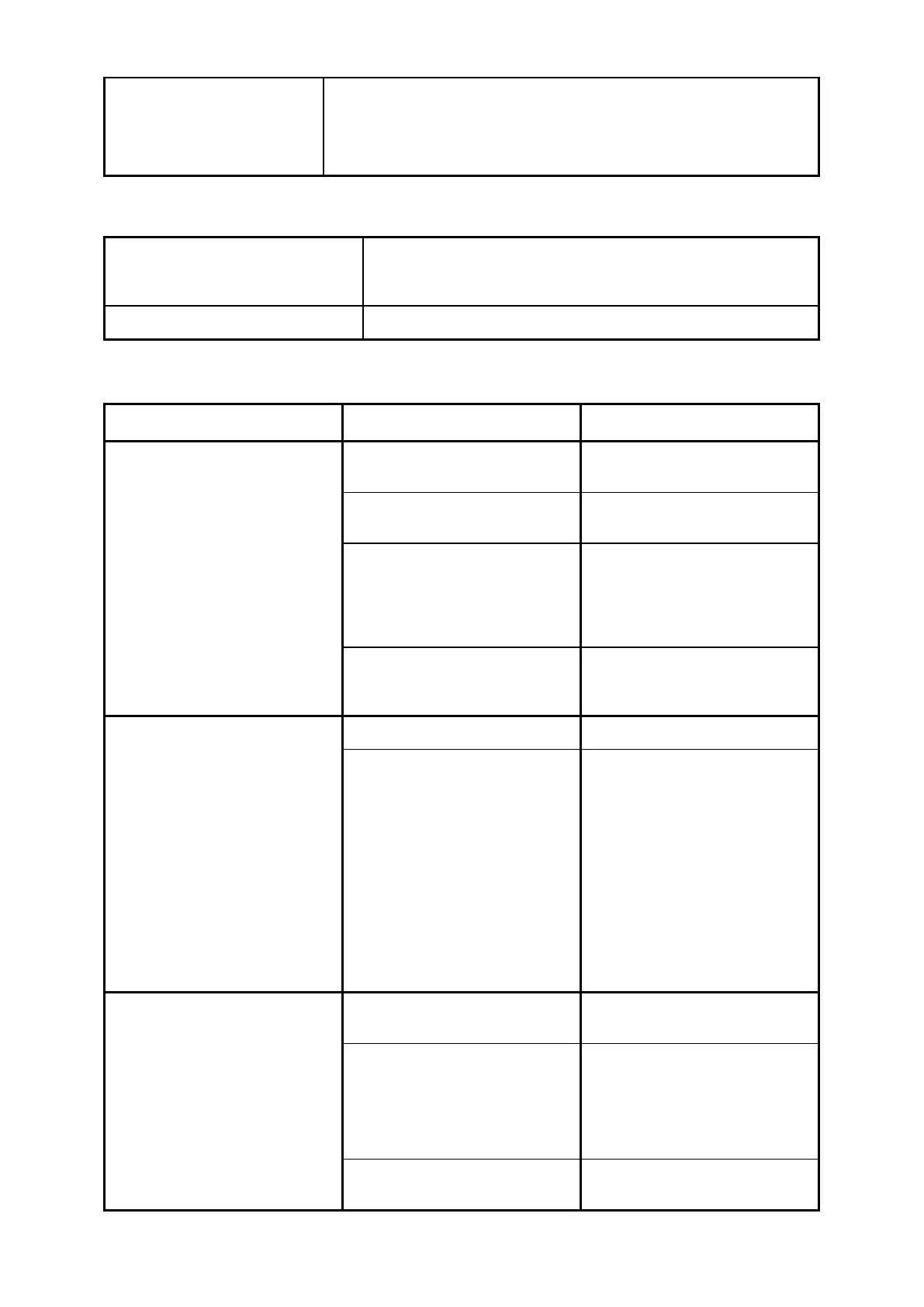

7 Trouble-shooting

(1) Neither abrasive nor air

Air valve of compressor is

Open air valve.

Blocked moisture separator. Check and clean moisture

Remote control valve RMS-

2000A (RMS 1500+500) or

RMM-50A (item 2) doesn’t work.

Check remote control valve and

remote control hoses for loose

conn

ections while outlet valve is

closed (depressed deadman

handle).

Electric remote controls:

magnetic valve of electric panel

RME (item 15) is blocked.

Disassemble and clean it.

(2) Air but no abrasive comes

out of nozzle.

Closed abrasive metering valve.

Open abrasive metering valve.

− Moist abrasive blocks

abrasive flow at bottom of

pot.

− No screen or cover.

− Several times open and close

choke valve (item 7) rapidly.

Attention! This measure

leads to increased wear of

the rubber nipple in the

abrasive metering valve

FSV (service life <50h)

− Open inspection door and

clean pot.

− Install an after cooler for air

(3) Irregular flow of abrasive

Incorrectly adjusted abrasive

Check adjustment and open it

Clogging.

− Check nozzle and gasket for

wear and replace them if

necessary.

− Open inspection plate of

metering valve and clean it.

Choke valve incorrectly

Correctly adjust choke valve.

Loading...

Loading...