BNP PRESSURE BLAST CONVERSION KIT Page 12

8.11.9 Check the 4-way valve per Sections 8.10.4 and

8.10.5.

8.11.10 Inspect the check valve for obstruction or broken

flap.

8.12 Static Shocks

8.12.1 Cabinet and/or operator not grounded. Abrasive

blasting creates static electricity. The cabinet must be

grounded to prevent static build-up. If shocks persist, the

operator may be building up static. Attach a small

ground wire (such as a wrist strap) from the operator to

the cabinet.

9.0 ACCESSORIES AND REPLACEMENT

PARTS

9.1 Optional Accessories

Description Stock No.

Storage segment, 16": Fits between the

reclaimer and blast machine. Provides nearly 2

additional cubic feet of media storage .................... 21128

Vortex cylinder assembly, adjustable

for exhauster mounted reclaimer

600 cfm ......................................................... 19062

900 cfm ......................................................... 23047

Flex hose, heavy lined, for heavy usage with

aluminum oxide. Available in 15 ft. lengths only

5" ID ................................................................. 12465

6" ID ................................................................. 12457

Boron carbide nozzle

CTB-2, 1/8" orifice ............................................. 21090

CTB-3, 3/16" orifice ........................................... 21091

CTB-4, 1/4" orifice ............................................. 21092

Lock pins (pkg of 25) for twist-on hose couplings .. 11203

Safety cable, blast hose ......................................... 15012

Manometer kit ......................................................... 12528

Abrasive trap .......................................................... 02011

Conversion kits, Sentinel metering valve

To convert from fine mesh media to coarse .... 22848

To convert from coarse mesh media to fine .... 22849

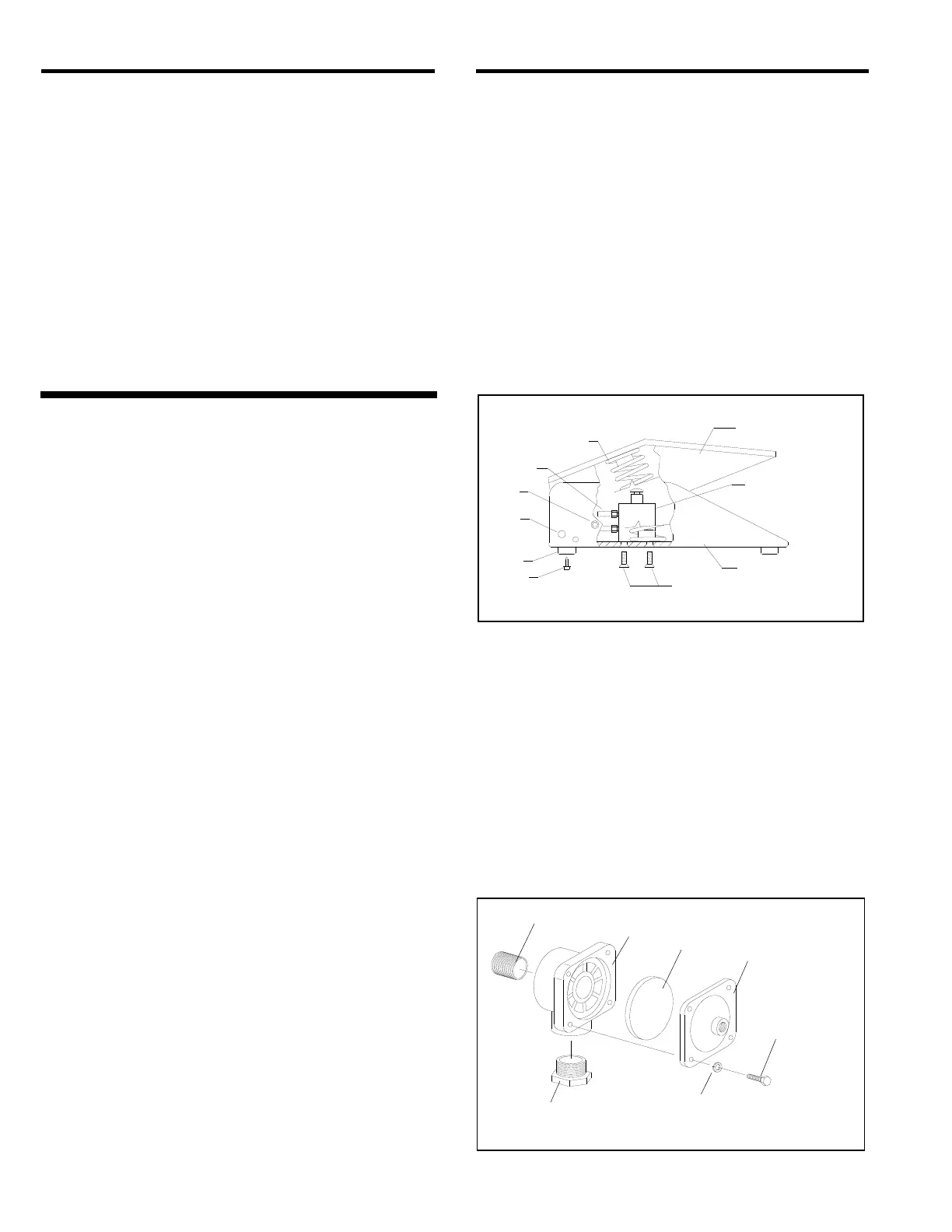

9.2 Foot Pedal Assembly, Figure 5

Item Description Stock No.

(-) Foot pedal assembly, less tubing ................. 20483

1. Top, foot pedal .............................................. 20017

2. Base, foot pedal ............................................ 19991

3. Valve, 3-way n/c ........................................... 20026

4. Drive pin, grooved ........................................ 20109

5. Screw, 1/4 nf x 3/4" soc. hd. ......................... 03086

6. Screw, 10-32 x 1/2" fh .................................. 19571

7. Adaptor, 10-32 thrd. x 1/8" barb ................... 11731

8. Spring, 1-1/4" x 3-1/2" .................................. 20121

9. Screw, 8-32 x 3/8 thread cutting ................. 11389

10. Bumper, rubber (feet) ................................... 21522

Figure 5

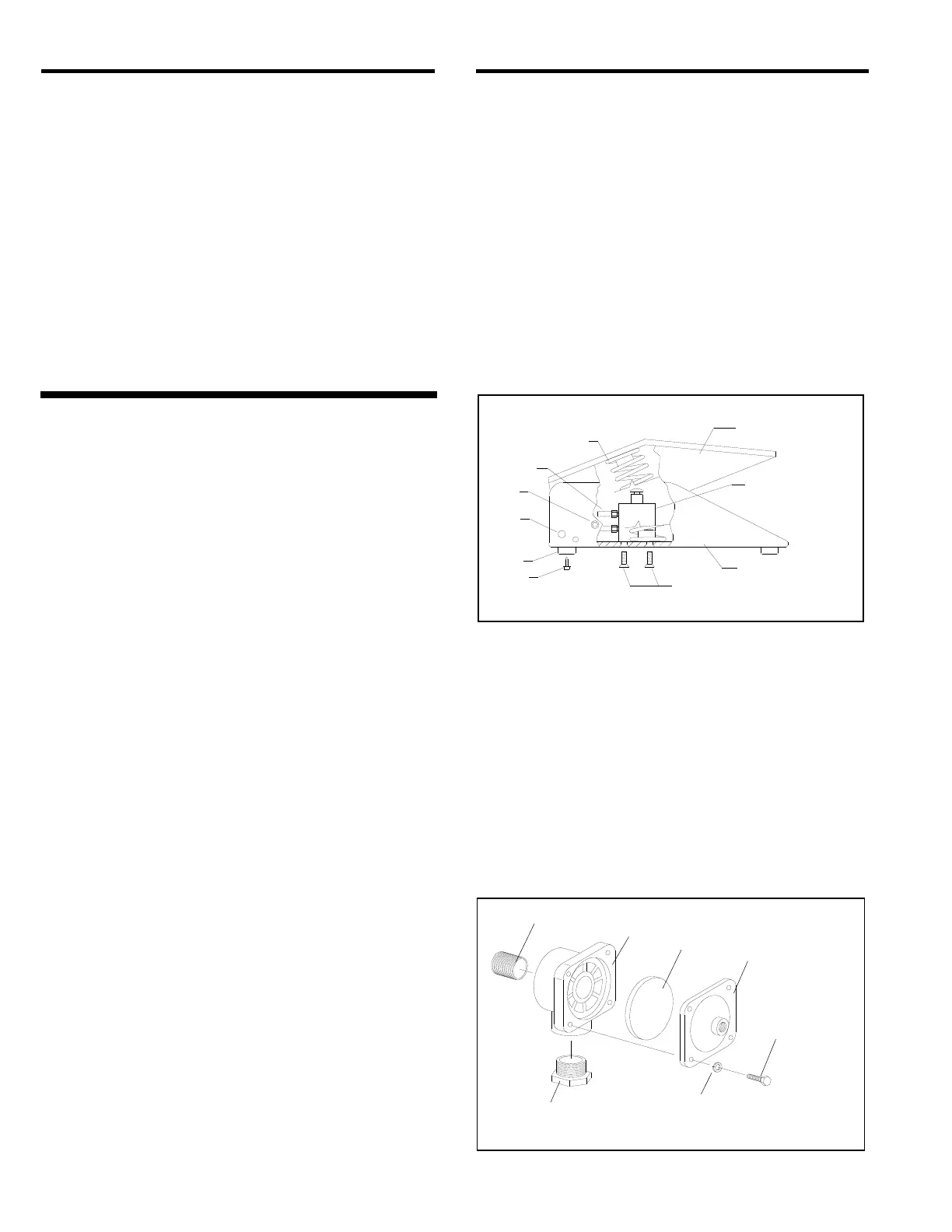

9.3 1" Diaphragm Outlet Valve, Figure 6

Item Description Stock No.

(-) 1" Diaphragm outlet valve, complete ............ 03371

1. Nipple, 1" x close .......................................... 01701

2. Diaphragm, outlet valve ................................ 06149

3. Lock washer, 1/4" ......................................... 03117

4. Cap screw, 1/4"x 1" ...................................... 03053

5. Cap, diaphragm outlet .................................. 03393

6. Body, diaphragm outlet ................................. 06135

7. Bushing, 1-1/4" x 1" ...................................... 01804

Figure 6

1

8

3

2

5

4

6

7

9

10

1

2

6

5

3

4

7

Loading...

Loading...